Evaporator temp (f) – Carrier 38SE User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 6 — Refrigerant Charging Methods (Carrier Approved Systems)

COND UNIT ;

METHODS OF CHECKING

OR ADJUSTING CHARGE

METHODS FOR

COMPLETE RECHARGING

System Refriqerant Control

System Refrigerant Control

AccuRater^M Capillary Tube

TXV

AccuRater Capíllary Tube

TXV

38GR

Chargemaster®

Charging Chart

er

Sight Glass

Weight Method

Plus

Chargemaster

Weight Method

Plus

Charging Chart

or

Sight Glass

38SE

Chargemaster

or

Charging Chart

Sight Glass

Weight Method

Plus

Chargemaster or

Charging Chart

Weight Method

Plus

Sight Glass

r

NOTE; 38SE operates at lower head pressure than comparable units Do not expect as high pressure when charging or adding charge

Table 7 — Chargemaster Charging Chart

(38GR Capillary Tube or AccuRater Systems)

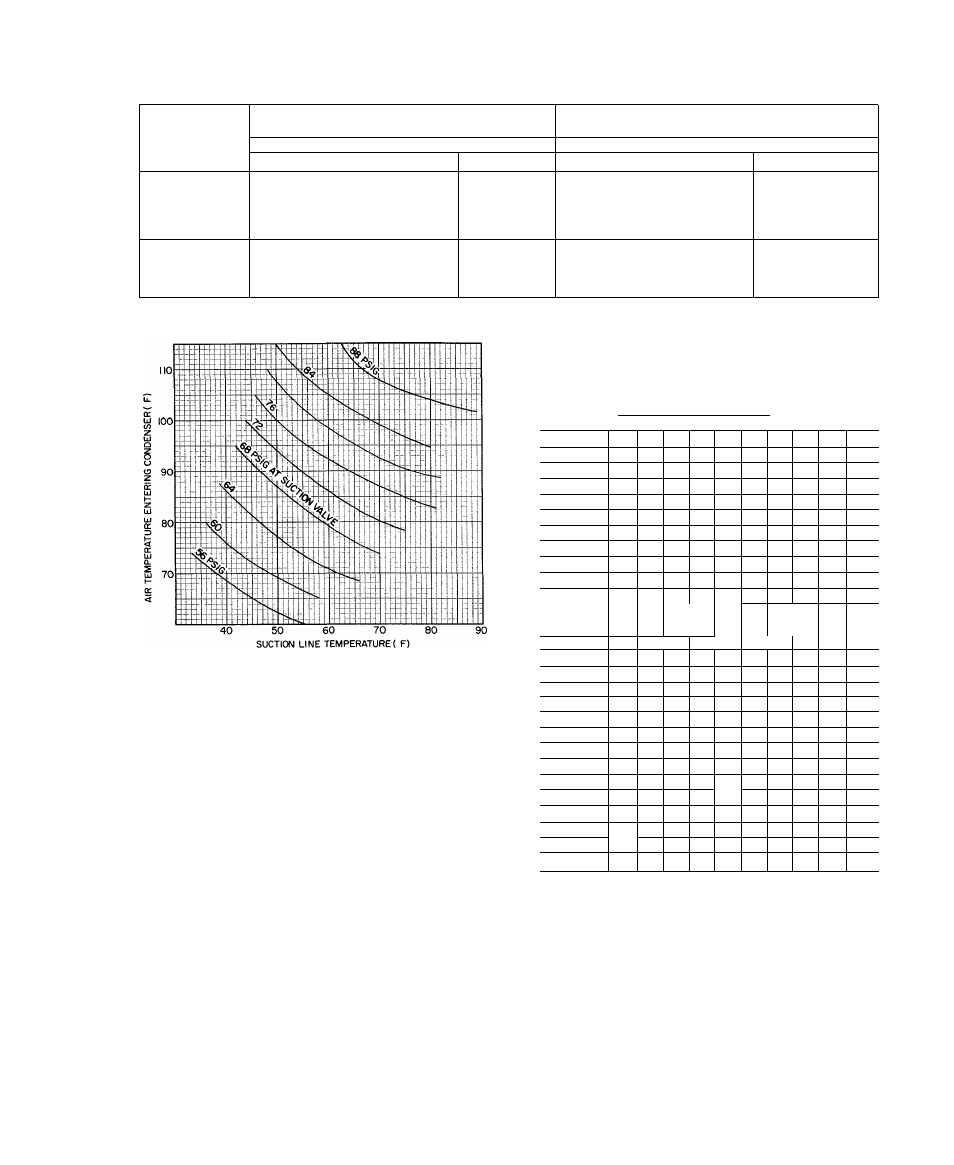

Fig. 6 — 38SE Charging Chart

(Capillary Tube or AccuRater Systems with or

without Suction-Liquid Line Heat Interchange)

7. Enter Chargemaster Charging Chart, Table 7 or 8, at

outdoor air temperature (step 5) and evaporator temper

ature (step 6). Find the suction line temperature

required for correct system charge. If actual suction line

temperature (step 6) is higher than table value, the

system is undercharged. If suction line temperature is

lower than table value, the system is overcharged.

Example: At outdoor air temperature of 85 F and

evaporator temperature of 44 F, the system will be

correctly charged at 71 F ±2 F suction line temperature.

See Table 8.

8. Add charge by slowly opening Chargemaster valve. If

necessary, reduce charge by bleeding at liquid line

service valve. Check outdoor air and evaporator temper

ature during procedure. If they change, refer back to

Suction Line Temperature table for new value.

Correct use of Chargemaster ensures an optimum refrig

erant charge will be in system when conditions and system

components are normal. However, the Chargemaster does

not solve or fix system abnormalities. It indicates correct

charge for condition of system. It will not make corrections

for dirty filters, slow fans, excessively long or short suction

lines or other abnormal conditions. This charging device

ensures that a correct relationship exists between outdoor

temperature, evaporator temperature, and suction line

temperature on a specific system.

OUTDOOR

TEMP (F)

EVAPORATOR TEMP (F)

21

I

25

I

28

I

31

I

34

I

37

Ml

43

I

45 48

Suction Line Temperotures

60

32

40

51

m

62

30

38

49

64

28

37

47

60

66

27

35

45

57

68

34

43

54

67

70

32

41

52

64

72

31

39

50

61

72"

74

30^

37

48

58

69"

76

29

36

46

56

66

78

27

35

44

54

63..

80

_

26

33

42

52

61 " w-

82

m

39

40

.50

80

76

—

86

29

37

46

55" "63

73

85

88

35

44

53

61

70

81

90

34

42

51

59

68

78

90

92

33

41

49

57

65

75

86

94

39

47

55

63

72

83

96

38

45

53

61

70

80

98

36

44

51

59

67

77

100

42

49

57

65

75

102

41

48

55

63

73

104

39

46

53

61

70

106

45

51

59

68

108

43

49

57

65

110

41

47

55

63

112

46

53

61

114

50

59

Example

*Saturated evaporator temperature which is the equivalent tem

perature of pressure taken at the condensing unitsuction service

valve

Sight Glass Method

— A satisfactory operating charge can

he obtained on thermal expansion valve systems by

charging to a clear sight glass. For optimum charge, elevate

high-side pressure to 380 ±10 psig by blocking condenser

fan discharge or condenser entering air. Charge to a clear

sight glass while holding high-side pressure constant. For

peak efficiency, adjust charge to yield a liquid refrigerant

temperature at the evaporator that is approximately the

same as outdoor dry-bulb temperature.