Start thermistor (ptc device) – Carrier 38SE User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carrier Standard Service Techniques Manual, Chapter 2, for

details. Use a 130 mfd start capacitor. Connect wires with

insulated probes to each capacitor terminal. Touch probes

to each side of run capacitor or to compressor motor

terminals R and S. Start compressor;

pull probes away after

3 seconds. Discharge start capacitor.

Run compressor for 10

minutes, then shut off and allow system pressure to

equalize. Try restarting without boost capacitor. If after 2

attempts (without boost capacitor) the compressor does

not start, add an accessory start capacitor relay package.

Unit Single-Phase Compressors

that are equipped with a

compressor

start thermistor (PTC device).

If compressor

will not start, check the thermistor with an ohmmeter as

follows;

1. Shut off all power to unit and wait 5 minutes for

thermistor to cool to outdoor temperature.

2.

Measure resistance of thermistor with ohmmeter.

Normal resistance readings are 50 to 90 ohms at 75 F

outdoor temperature.

3. If ohmmeter resistance reading is 0 or much higher than

90 ohms, the thermistor is defective and must be

replaced.

If start thermistor (PTC device) is good and compressor

will not start, disconnect the thermistor from starting circuit

and give compressor a temporary capacitance boost as

described above. Run compressor for 10 minutes, then shut

off and allow system pressure to equalize. Reconnect start

thermistor and try restarting compressor without boost ca

pacitor. If after 2 attempts the compressor does not start,

remove thermistor and add an accessory start capacitor re

lay package.

Compressor Removal

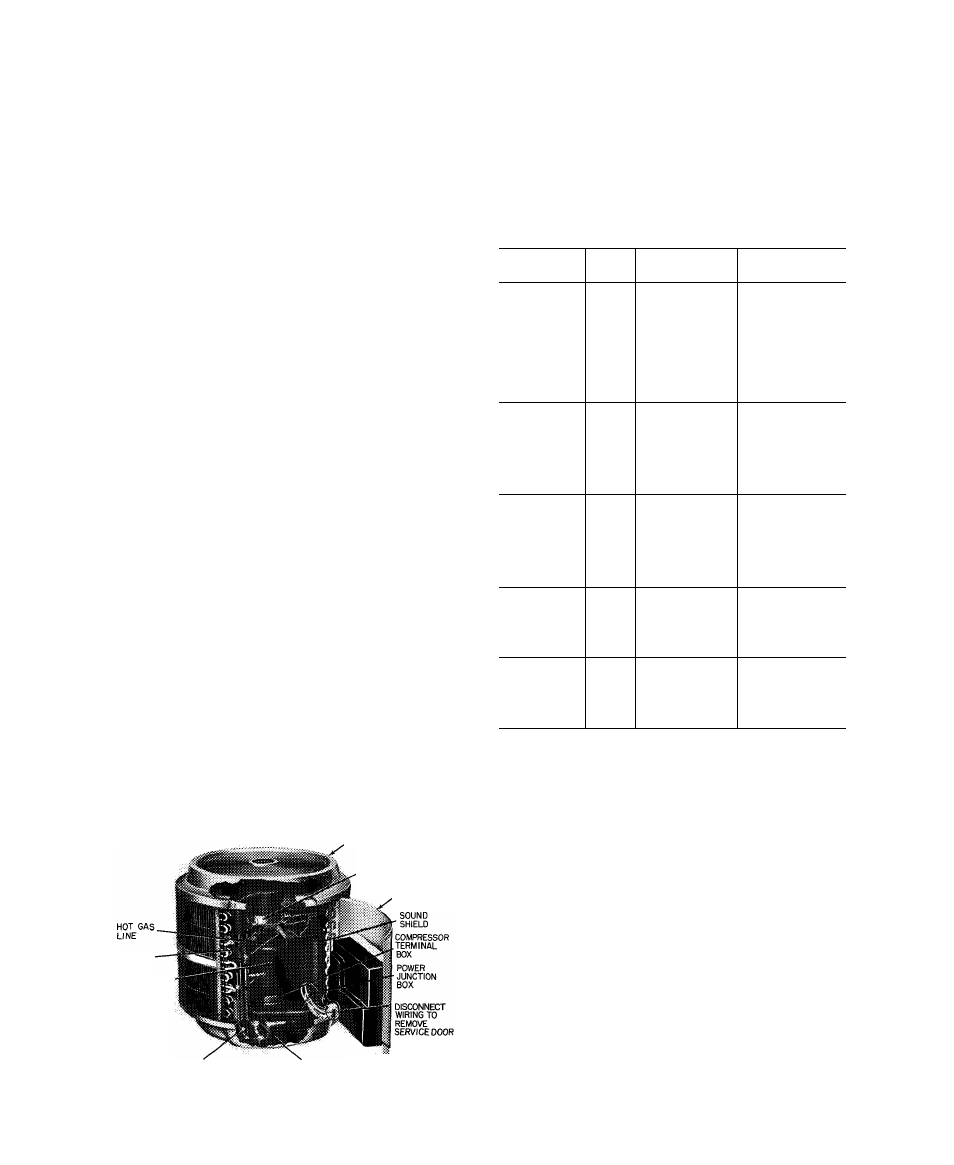

38GR; 38SE002,003,004 UNITS - See Table 9 for

compressor information and Fig. 8 for component location.

Shut off power to unit. Vent refrigerant to atmosphere or

use refrigerant removal methods shown in Carrier Standard

Service Techniques Manual, Chapter 1.

1. Remove unit top cover (grille). Open or remove service

door.

2. Disconnect fan motor leads from control panel located

on service door. See Fig. 7 and refer to Service Door on

page 3. Remove 6 screws holding fan motor orifice

assembly in place and lift assembly from unit.

3. Compressor outer sound shield is fastened to tube sheets

and to base pan. Loosen screws and remove sound shield

by sliding it straight up using tube sheets as guides.

4. (38SE only) — Warp top cover of inner compressor

sound shield upward to clear compressor process tube.

Carefully slide cover over the tubing.

.TOP GRILLE COVER

FAN MOTOR-ORIFICE

ASSEMBLY

SERVICE

DOOR

SUCTION

LINE

COMPRESSOR

5. (38SE only) — Slide inner compressor sound shield

terminal box cover upward and out.

6. Remove compressor terminal box cover, disconnect and

remove compressor power leads.

7. (38SE only) — Lift off inner compressor sound shield.

8. Unsweat suction and hot-gas lines.

9. Remove compressor hold-down bolts. Lift compressor

out thru top of unit.

Table 9 — Compressor Data

COND

V/PH

PRODUCTION

OIL RECHARGE

UNIT

COMPRESSOR*

(oz)

38GR002---

38GL400324

40.5

38GR002320

MD2723CB

43.2

38GR003---

38GR400234

31.5

38GR0033I0

MC3423CB

43.2

38GR004---

230/1*

38GC401564

45.0

38GR0043IO

MC4023CB

43.2

38GR045---

PC4Ó26AD

76 0

38GR005---

PC5326AD

76.0

38GR006---

PC6725AB

76 0

38GR003---

RF3522CJ

50.4

38GR0034Í0

MF3423CB

43 2

38GR004---

RF3922CJ

50 4

38GR0044Í0

200/3

MF4023CB

43.2

38GR045---

PF4626AD

76.0

38GR0£)5---

PF5326AD

76.0

38GR006---

PF6725AA

76 0

38GR003---

RG3522CJ

50.4

38GR0035I0

MG3423CB

43 2

38GR004---

RG3922CJ

50.4

38GR0045Í0

230/3

MG4023CB

43.2

38GR045---

PG4626AD

76.0

38GR005---

PG5326AD

76 0

38GR006---

PG6725AA

76 0

38GR004---

RH3922CJ

50 4

38GR0046Í0

MH4023CB

43 2

38GR045---

460/3

PH4626AD

76.0

38GR005---

PH5326AD

76.0

38GR006---

PH6725AA

76.0

38SE002---

MD2023CB

43 2

38SE003---

MD2723CB

43.2

38SE004---

230/1

MC3423CB

43.2

38SE045---

PC4Ó26AD

76 0

38SE055---

PC5326AD

76.0

LIQUID VALVE

SERVICE PORT

SUCTION VALVE

SERVICE PORT

JCONTROL

»PANEL

COVER

Fig. 8 — 38GR Condensing Unit with Service Door Open

shown italicized

000.

* Refer to Service Parts catalog for replacement compressor model

numbers.

The 38GR.SE single-phase compressors include start

assist.

38SE045,055 UNITS

1. Open and remove service door. See Fig. 7 and refer to

Service Door on page 3.

2. Disconnect fan motor leads and crankcase heater leads

from control panel located on service door.

3. Remove cover plate on compressor terminal box and

disconnect all leads.

4. Remove 4 screws holding compressor plastic sound

shield in place. Slide shield upward 6 to 10 inches.

5. Unsweat suction and hot-gas lines at compressor (dis

connect convenient connection at sight glass or filter-

drier).

6. Remove 3 screws holding coil to base pan.

7. From front of unit (coil-emblem side) hft complete

disconnected coil-fan-top cover assembly off from

compressor-base pan assembly.

10