Service door, Electrical data and wiring – Carrier 38SE User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

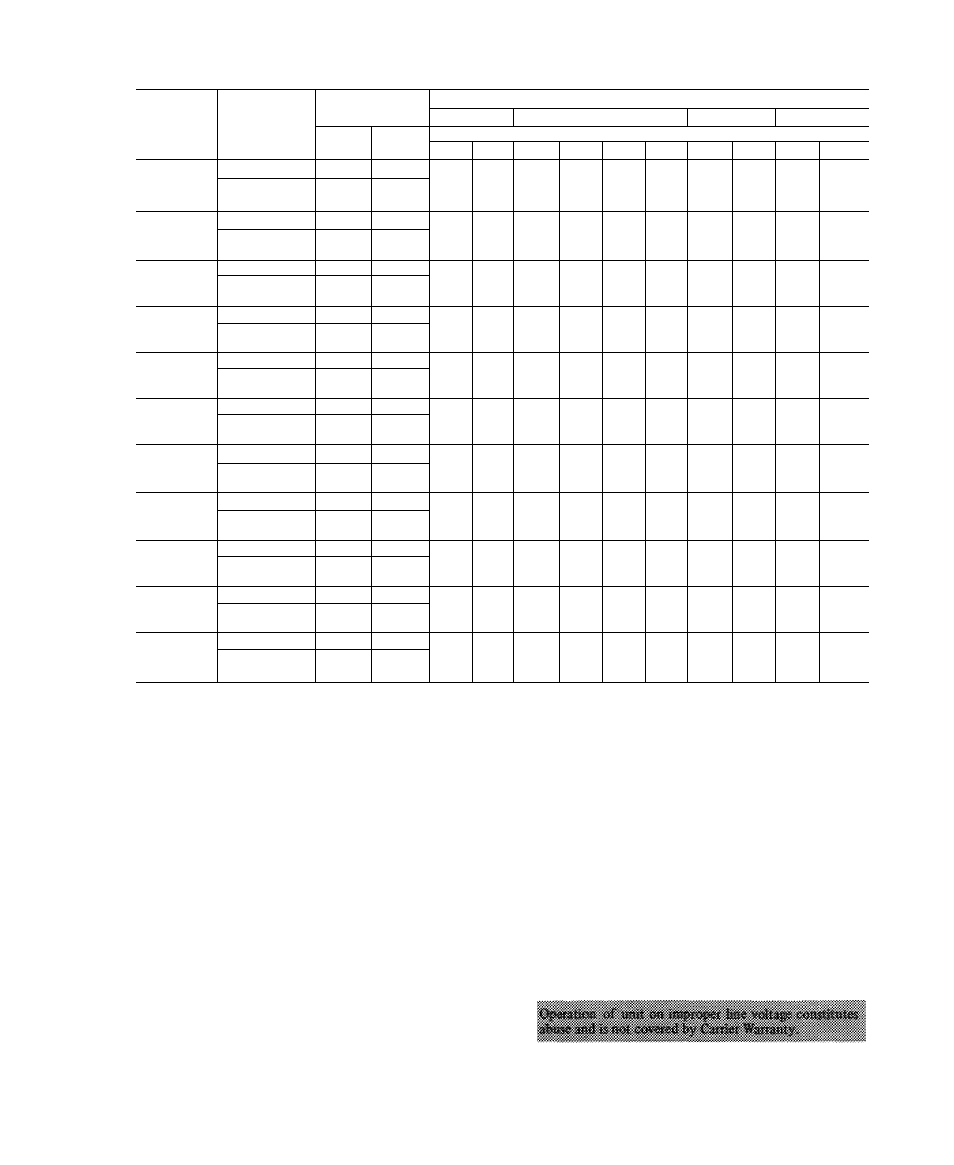

Table 3 — Field-Supplied Piping Data

COND

UNIT

REFRIG

CONTROL

MAX COND

UNIT HT (ft)

REFRIGERANT LINE LENGTH (ft)

25-50

51-75 76-100

101-125

126-150

Above

Evap

Below

Evap

Line Diameter (in. OD)

Suet

Liq

Suet

Liq

Suet

Liq

Suet

Liq

Suet

Liq

38GR002

TXV

90

90

%

V

4

Vs

V

4

Vs

V

4

Vs

V

4

Vs

Cap. Tube or

AccuRater'*'^

150

50

38GR003

TXV

90

90

%

%

V

4

Vs

V

4

Vs

V

4

Vs

V,

Vs

Cap. Tube or

AccuRater

150

50

38GR004

TXV

90

90

^4

%

V

4

Vs

Vs

Vs

Vs

V

2

Vs

Va

Cap. Tube or

AccuRater

150

50

38GR045

TXV

90

90

%

%

Vs

V

Vs

V.

Vs

V

Vs

Va

Cap. Tube or

AccuRater

ISO

50

38GR005

TXV

90

90

IVs

%

IVs

V

IVs

V

IVs

V

IVs

Vs

Cap. Tube or

AccuRater

150

50

38GR006

TXV

90

90

iVs

%

IVs

Vs

IVs

Vs

IVs

Vs

IVs

Vs

Cap. Tube or

AccuRater

150

50

38SE002

TXV

90

90

V

u

V

'8

V

/A

Vs

Vs

Vs

V

/8

Vs

Vs

Vs

Cap. Tube or

AccuRater

150

50

38SE003

TXV

90

90

Vs

V

'8

Vs

V'8

Vs

Vs

Vs

Vs

Vs

V'8

Cap. Tube or

AccuRater

150

50

38SE004

TXV

90

90

IVa

%

IVs

%

IVs

Vs

IVs

Vs

IVs

Vs

Cap. Tube or

AccuRater

150

50

38SE045

TXV

90

90

IVs

\

IVs

V

IVs

V

2

IVs

V

IVs

Va

Cap. Tube or

AccuRater

150

50

38SE055

TXV

90

90

iVa

%

IVs

V

IVs

V.

IVs

Va

IVs

Vs

Cap. Tube or

AccuRater

150

50

Cap. Tube — Capillary Tube

TXV — Thermal Expansion Valve

NOTES:

1 Systems with over 50 ft separation between condensing unit and evaporator require refrigerant

charge adjustment to ensure the proper superheat at compressor See Refrigerant Charging, page

5 Oil charge adjustment may also be required

2

Reduce liquid line diameter by 1/8-in OD (minimum 1/4-in OD) when evaporator is 20 ft or

more below condensing unit

3. Insert tube into compatible fitting. Wrap top and

bottom of service valves in wet cloth to prevent damage

by heat. Solder with low-temperature (450 F) silver

alloy solder.

4. Replace Schrader core.

5. Evacuate or purge system with field-supplied refrigerant.

SERVICE DOOR

Service door can be opened or removed for wiring or

servicing unit

Remove 3 screws from left side of service door (Fig. 1)

to swing door open.

Door Removal

— Turn power off. Disconnect wiring from

control panel mounted on door. Refer to Fig. 7 and 8.

After wiring is disconnected, lift door from roll pin hinges.

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and national fire,

safety and electrical codes. Voltage to unit must be within

± 10% of voltage indicated on nameplate. On 3-phase units,

phases must be balanced within 2%. Contact local power

company for correction of improper line voltage.

See Table 4 for recommended wire and fuse sizes. When

making electric connections, provide clearance at unit for

refrigerant piping connections.