Carrier 38SE User Manual

Air-cooled condensing units, Number one air conditioning mater

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Number One

Air Conditioning

Mater

e

Division of Carrier Corporation

Carrier Parkway ♦ Syracuse NY 13201

Air-Cooled Condensing Units

SUCTION LINE CONN (ON SERVICE VALVE)

LIQUID LINE

CONN.(ON SERVICE,!

VALVE)

5." |3'*

16 “ ' 8

MTG SLOTS

(USE ANY 2) ------- ------- 10^

uSl SPACE REQUIRED FOR SERVICE

38SE,GR

DIAM

HOLE

FOR

CONTROL

WIRIN(3

CONCRETE MOUNTING PAD^(SQUARE OR CIRCULAR)

^CONCRETE PAD SHOULD WEIGH |-| TO 2 TIMES WEIGHT OF UNIT

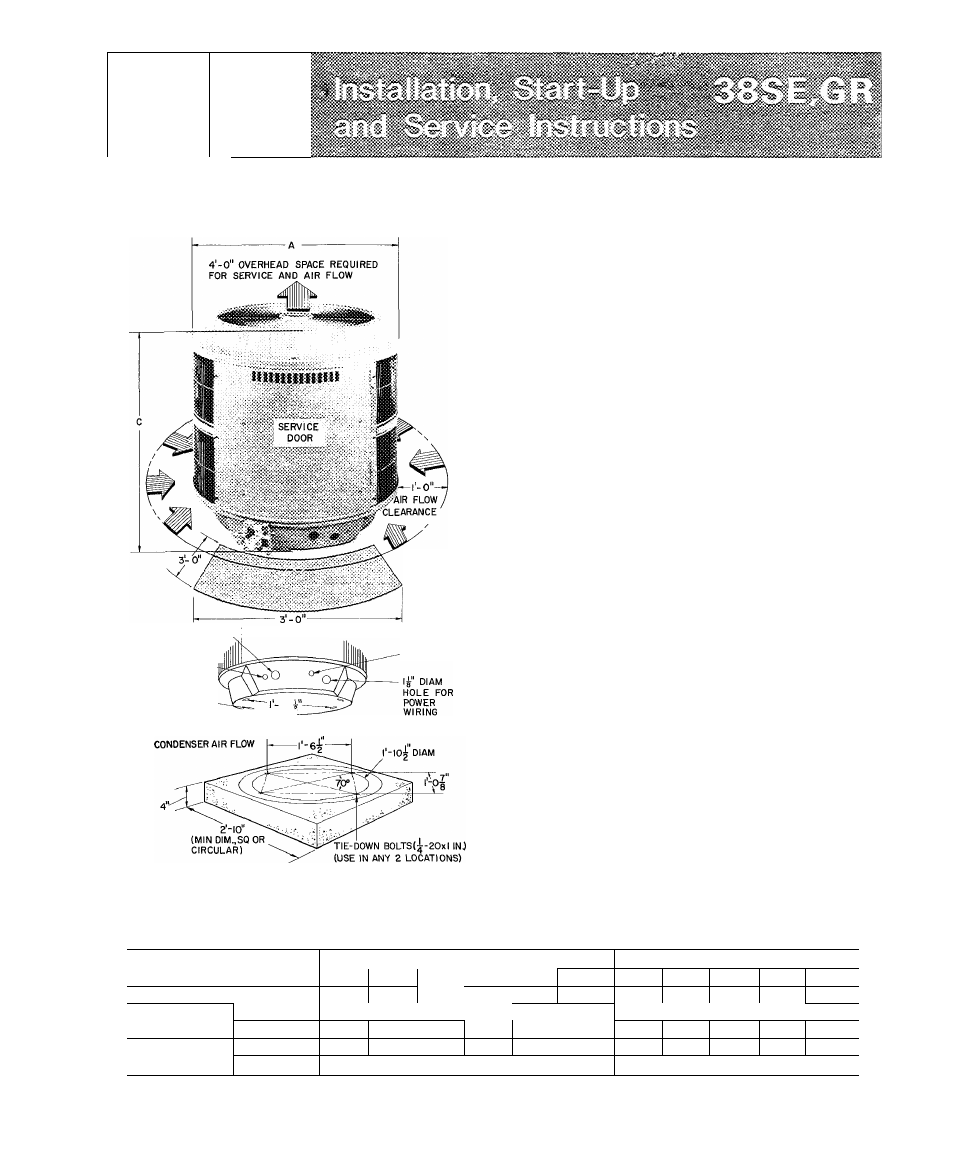

Fig. 1 — Dimensions, Connections and Mounting Pad

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is

damaged or incomplete.

PRELIMINARY SURVEY

Consult local building codes and National Electrical

Code (NEC) for special installation requirements.

When installing unit, allow sufficient space for airflow

clearance, wiring, refrigerant piping and servicing unit.

Recommended minimum requirement is 3 ft (Fig. 1).

Position unit so water from roof or eaves will not pour

directly on top of unit.

Install unit on a solid, level mounting pad. Position

tie-down bolts in pad. Any 2 holes in unit base may be used

to fasten unit to pad.

38GR Condensing Units Connected to Carrier-Approved

Evaporators with Carrier Accessory Tubing

— 38GR units

contain correct refrigerant charge when evaporator is same

size, or one size larger than condensing unit and are

connected with Carrier accessory tubing. Check refrigerant

charge when tubing lengths are above 50 feet. See Refrig

erant Charging for details.

38SE Condensing Units Connected to Carrier-Approved

Evaporators

— 38SE units contain correct system refrig

erant charge when evaporator is same size as condensing

unit, and they are connected with 25 ft or less of

field-supplied tubing of recommended size (see Piping

Connections) or 50 ft or less of Carrier accessory tubing.

Check refrigerant charge for maximum system efficiency.

See Refrigerant Charging for details.

38GR,SE Condensing Units Connected to Non-Carrier

Evaporators

— Check refrigerant charge when the 38GR,SE

is added to a system in which other than a Carrier approved

evaporator is being used or where the evaporator has been

previously installed. Field-supplied refrigerant piping must

be in accordance with Refrigerant Piping Data table.

Use an evaporator coil with a bleed-type expansion

device. If coil does not have a bleed-type expansion device

it may be necessary to add an accessory start capacitor and

relay to condensing unit. This would require removing

compressor start thermistor (PTC device) on units so

equipped.

PIPING CONNECTIONS

The 38GR,SE condensing units can be connected to

evaporator sections using Carrier accessory tubing package

or field-supplied tubing of refrigerant grade (Accessory

Table 1 — Installation Data

CONDENSING UNIT

38GR

38SE

002

003

004

045

005

006

002

003

004

045

055

OPERATING WT (lb)

151

170

182

194 1 234

260

176

180

192

248

255

DIMENSIONS

Diam A

2-5У4

2-5У4

(ft-in.)

Height В

2-4

2-4

2-4

2-4

2-8

2-8

2-4

2-4

2-8

3-8

3-8

REFRIG

Suet ODF

%

y.

L

V

'A

’/

4*

3/*

V

4

У

4

У

4*

3/*-

4

%*

CONN.

Liq ODF

V

4

Ys

*38GR005,006 and 38SE004,045,055 supplied with 3/4-in to 1 1 /8-in suction valve connection adapter (field installed) for 1 1 /8-in suction

line (field supplied)

© Carrier Corporation 1975

Fornn 38SE-3SI

Document Outline

- Air-Cooled Condensing Units

- TRANSPORTATION DAMAGE

- PRELIMINARY SURVEY

- PIPING CONNECTIONS

- Table 2 — Accessories

- PART NO.

- HH07AT070,

- DESCRIPTION

- 32LT900301

- 38GB900021

- UNIT

- UNIT

- 38SE002,003

- 38GR002,003,004,045

- 38SE004

- 38GR005,006

- SERVICE DOOR

- ELECTRICAL DATA AND WIRING

- Fig. 2 — Line Power Connections

- START-UP INSTRUCTIONS

- Start Procedure

- SERVICE

- REFRIGERANT CHARGING

- EVAPORATOR TEMP (F)

- UNIT PROTECTION

- PUMPDOWN PROCEDURE

- COMPRESSOR SERVICE

- COMPATIBLE FITTING REPAIR

- Fig. 9 — Repair of Mechanical Connection

- Fan Motor Removal

- CONDENSER

- LUBRICATION