Load recycle ■ □ n, N□ n, Press on-stop button (light goes on). ■ □ n – Carrier 17CB User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Start chilled water and

condenser water pumps.

Press ON-STOP button

(Ught goes on).

6. Press OIL PUMP button

for several seconds. Pump

should raise pressure 25 to

27 psi above refrigerant

pressure

at

machine

shutdown

condition.

SAFETY CIRCUIT and

lights should go on.

7.

R e l e a s e O I L PUMP

button.

SAFETY

CIR

CUIT light and LOAD

RECYCLE light should go

out.

■

□

n

ON

STOP

START

OIL

PUMP

■

□ □

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

■

□

■

ON

STOP

START

OIL

PUMP

■ ■ ■

□

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

LOAD RECYCLE

■

□

n

ON

STOP

START

OIL

PUMP

■

□ □

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

8. With OIL PUMP button

depressed, alternately stop

and restart chilled water

and

condenser

water

pumps. SAFETY CIR

CUIT and LOAD RE

CYCLE lights should go out as each pump

stops. (Continuous operation of oil pump is

unnecessary during these checks.)

■

□

■

ON

STOP

START

OIL

PUMP

■ □ □

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

9. Shut off water pumps. Re

lease OIL PUMP button.

Press ON-STOP button

(light out). Replace tagged

wire on terminal fl 7j.

10

.

n

□

n

ON

STOP

START

OIL

PUMP

■

□ □

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

Press ON-STOP button

(light goes on).

■

□

n

ON

STOP

START

OIL

PUMP

■

■ ■

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

11. Press machine START

b u t t o n ( m o t o r leads

disconnected).

Oil pump starts within 30

seconds.

Compressor motor start

contacts

will

close

30

seconds later. Starter will

transfer to its run condi

tion 30 to 60 seconds

after starter is energized.

■

■

n

ON

STOP

START

OIL

PUMP

■ ■ ■

■

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

■

■

■

ON

START

OIL

STOP

PUMP

■ ■ ■

■

POWER SAFETY LOAD

PROGRAM

CIRCUIT RECYCLE

TIMER

■

■

■

ON

STOP

START

OIL

PUMP

■ ■ ■

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

12. Open oil pump main dis

connect. Starter must de

energize. OIL PUMP light

will remain on for approxi

mately 5 minutes.

OIL PUMP light goes out.

■

□

■

ON

STOP

START

OIL

PUMP

■ □ □

■

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

■

□

□

ON

STOP

START

OIL

PUMP

■ □ □

■

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

13. Close oil pump discon

nect. In approximately 10

minutes the program timer

will complete the anti

recycle portion of its cycle

and machine is ready to restart. (Total recycle

time is 15 minutes.)

■

□

n

ON

STOP

STAffT

OIL

PUMP

■

■ ■

n

POWER SAFETY

LOAD

CIRCUIT RECYCLE

PROGRAM

TIMER

14. Remove all power.

Restore power.

Reconnect motor leads.

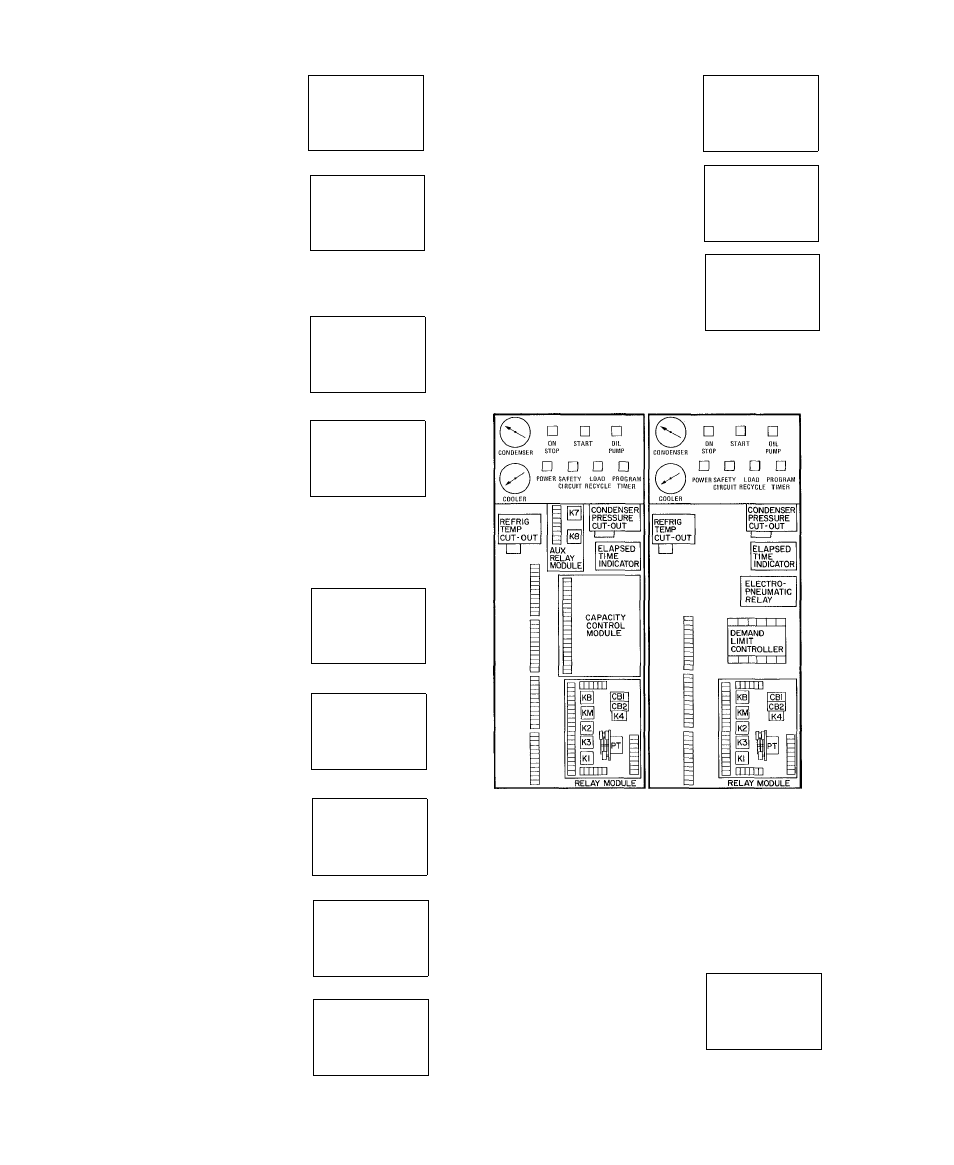

ELECTRONIC CONTROL

PNEUMATIC CONTROL

Fig. 6 — Control Center Components

(Electric Motor Drive)

Check Safety Control Operation (Gas Engine or

Turbine Drive)

Refer to machine control schematic in the

Operating and Maintenance Instructions for loca

tion of electrical terminals listed.

As checks are made, control panel lights

should appear as indicated in the diagrams.

1. Turn off main steam or

gas supply to prevent

drive from starting. Place

jumpers across oil switch

terminals (67} and

and flow switch terminals [69j and [70] inside

the control center.

□ □ □

POWER

ON

STOP

START

o

T

p

(g) □

OIL

PUMP

□

SAFETY

CIRCUIT