Carrier 17CB User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

DEMAND LIMIT CONTROL

CALIBRATION

ADJUSTMENT

BANDWIDTH

DIAL

% LOAD DIAL

COVER

1. Set percent load dial at 100%.

2. Set Band Width dial at 3.

3.

Turn Calibration Adjustment screw fully

clockwise.

4. Run machine at 100% LLA by adjusting dial on

chilled water thermostat.

5. Turn Cahbration Adjustment screw counter

clockwise until guide vanes just begin to close.

6.

If hunting occurs, increase band width and

repeat steps 4 and 5.

7.

If control cannot be calibrated with above

procedure, check voltage signal from resistor in

starter. At 100% full load, voltage between

terminals 23 and 24 inside control center must

be 3.0 ± 0.1 volts. If not in this range, check

sizing of resistor in starter.

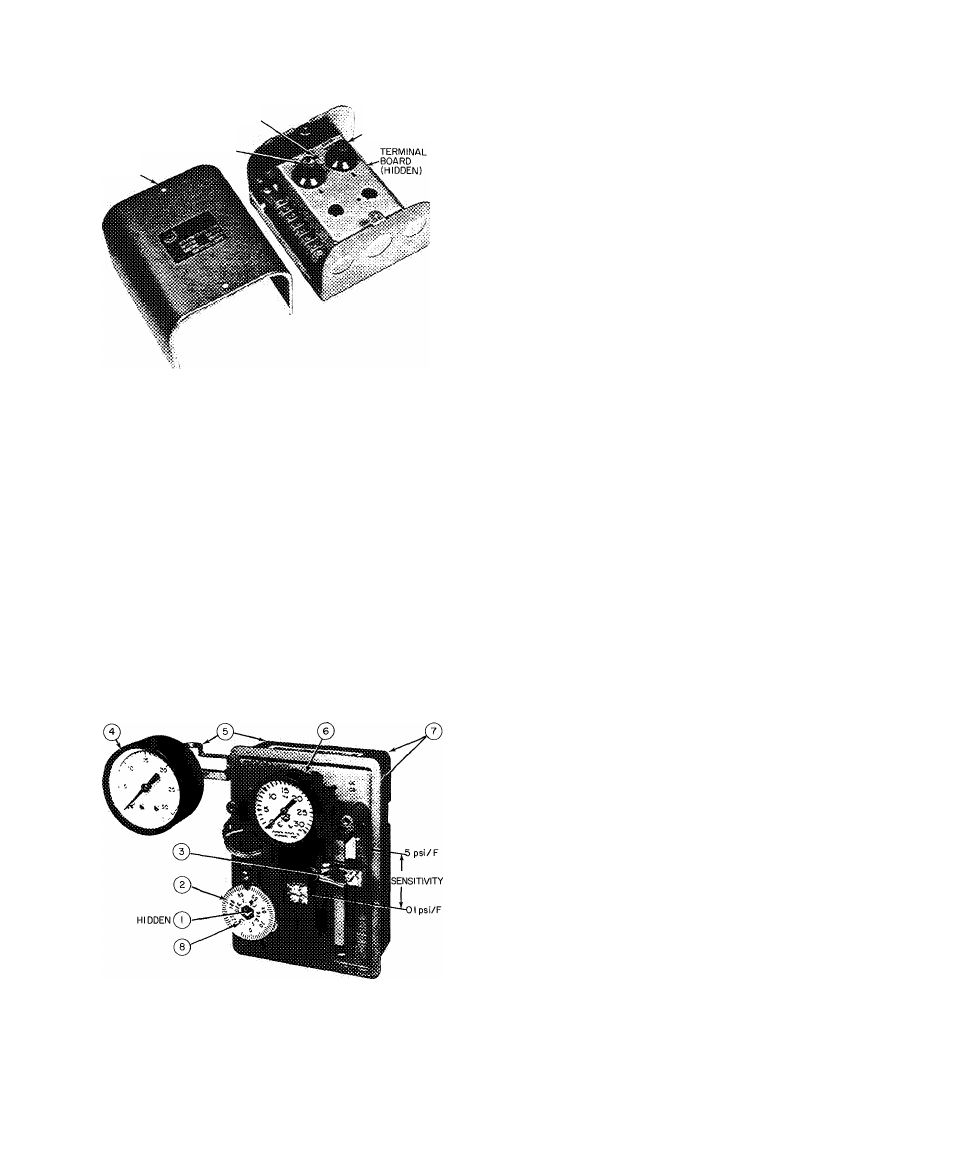

CHILLED WATER THERMOSTAT (PNEUMATIC)

ITEM

DESCRIPTION

1

SET POINT ADJUSTING SCREW

2

THERMOSTAT DIAL

3

SENSITIVITY SLIDER

4

SUPPLY AIR PRESSURE GAGE

5

SUPPLY AIR CONNECTIONS

6

CONTROL AIR PRESSURE GAGE

7

CONTROL AIR CONNECTIONS

8

DIAL RETAINING SCREW (2)

Preparation;

1. Ensure 25 psi supply air to thermostat.

2. Loosen Allen setscrew in sensitivity slider and

move slider halfway between midpoint and DA.

Re tighten screw.

Cahbration:

1. Turn thermostat dial until control air registers

15 psi.

2. Operate machine to reach design chilled water

temperature at design load. Maintain 15 psi

control air during pulldown by adjusting ther

mostat dial as required.

3. On reaching design chilled water temperature,

turn dial until control air pressure holds

machine at design conditions.

4. Hold setpoint adjusting screw stationary within

the dial post and set the thermostat dial at

design chilled water temperature.

^ Completion:

If vane hunting occurs, move sensitivity slider

away from DA. Sensitivity decreases as slider is

moved from 5 psi/F to the lower limit of 0.1 psi/F.

Trimming Refrigerant Charge

— After machine is

placed in operation, it may be necessary to adjust

the refrigerant charge to obtain optimum machine

performance.

When machine full load is available, slowly add

a sufficient amount of the remaining 200 lb of

refrigerant until the difference between leaving

chilled water temperature and cooler temperatures

reaches design conditions or becomes a minimum.

Shut down machine. Mark maximum refrigerant

level. Maintain refrigerant at this level.

Hot Alignment Check

— When all machine com

ponents have reached operating temperature (after

running near full load for approximately two

hours), a hot alignment check must be made.

1. Shut down machine.

2. Quickly disassemble couplings between com

pressor and drive (and gear, if used).

3. Check angular and parallel alignment in plan and

elevation. Indicators may be mounted as in Fig.

10. Refer to coupling manufacturer’s instruc

tions and to Carrier Standard Service Tech

niques, Chapter 15, for applicable procedures.

4.

After making adjustments, reassemble the

couplings and run the machine until it reaches

operating temperature.

5. Repeat steps 1 thru 3 until angular and parallel

alignment is within coupling manufacturer’s

specified tolerances.

14