Pumpout procedures, refrig 114 units (see fig. 3) – Carrier 17CB User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

r ^

2.

Charge approximately 25 lb of the proper

refrigerant thru the cooler charging valve.

3. Pressurize machine to test pressure (Table 1)

using dry air or nitrogen, or purge or pumpout

unit. Do not exceed test pressure.

4. Test all joints, valves, fittings etc. with a halide

or electronic leak detector.

Check Leakage Rate

1. Install a mercury manometer (absolute pressure

type) on a tee at the cooler charging valve.

2. Pull 25 in. of vacuum on the machine.

3. Let machine stand with this vacuum for at least

8 hours.

4. If leakage rate is less than 0.1 in. Hg in 24 hours

(0.033 in. Hg in 8 hours), machine is suffi

ciently tight. Perform Machine Dehydration.

5. If leakage rate exceeds 0.1 in. Hg per 24 hours,

repeat Check for Small Leaks, repair leaks and

repeat this Leakage Rate Check.

6.

Remove or valve off manometer before re

peating any pressure test.

Machine Dehydration

Before dehydration, drain shipping oil and flush oil

reservoir. Shipping oil vaporizes under vacuum and

can greatly inhibit dehydration.

CAUTION: Do not attempt to start oil pump

or purge motor even for a rotation check, nor

apply test voltage of any kind while machine is

under

dehydration

vacuum.

Motor

insulation

breakdown and serious damage may result,

1. Connect dehydration pump to cooler charging

valve.

2. Ensure that all valves on purge assembly are

closed.

3. Install mercury thermometer (absolute pressure

type) at charging valve tee.

4. Operate pump until manometer reads 29.80 in.

Hg vacuum (0.1 psia). Continue to operate

pump for 2 more hours.

5. Close cooler charging valve; stop pump; record

manometer reading.

6. Wait 2 hours and read manometer again. If

vacuum has not decreased, dehydration is com

plete. If vacuum has decreased, repeat steps 4, 5

and 6.

7. If vacuum fails to hold after several dehydra

tion attempts, check for machine leak by

repeating the refrigerant pressure test.

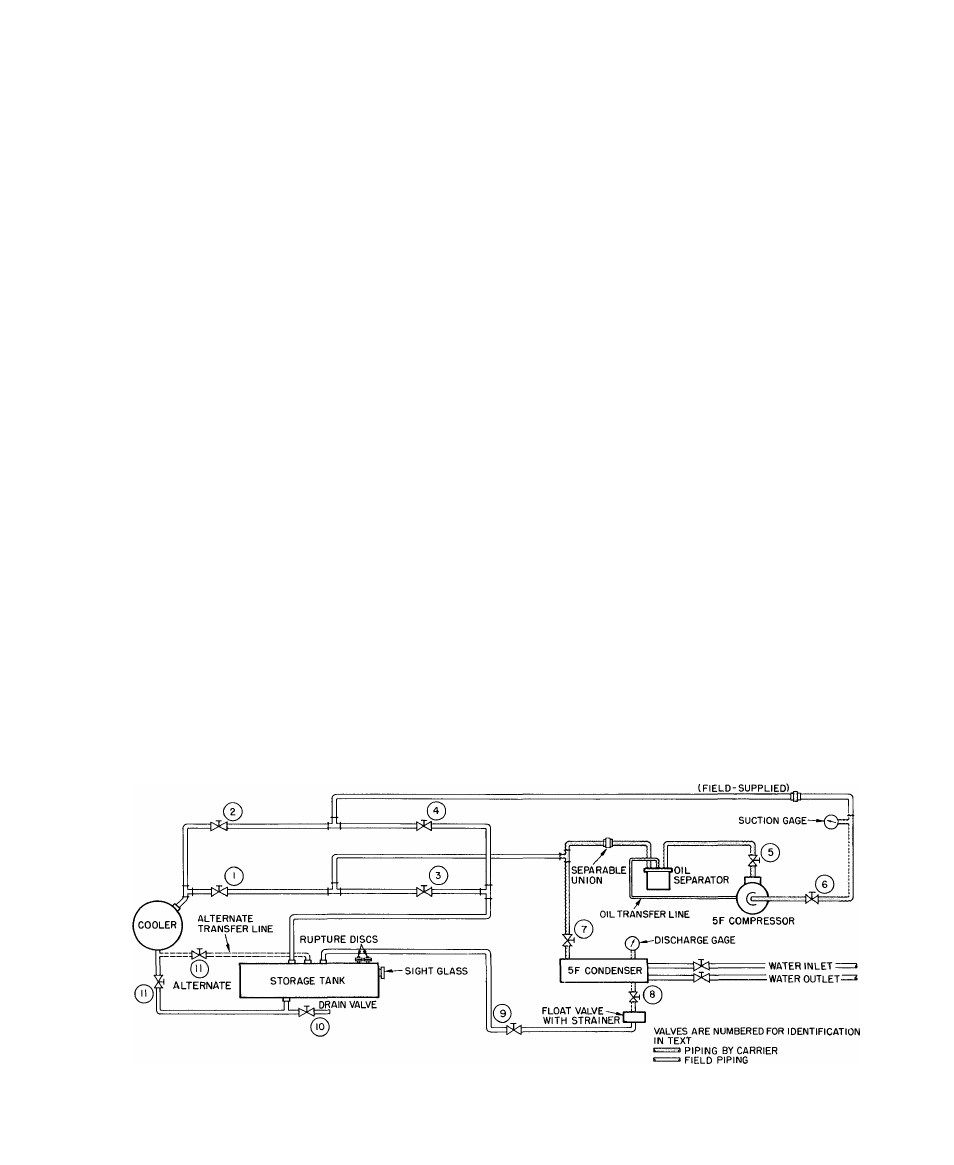

Pumpout Procedures, Refrig 114 Units (See Fig. 3)

MACHINE EVACUATION (No refrigerant in

system)

1. Set purge valves per operation 5 on purge valve

operation plate.

2.

Jumper low-pressure cutout on pumpout

compressor.

3. Close valves 1 , 3 , 7 and 10.

4. Open valves 2, 4, 5, 6, 8, 9 and 11.

5. Disconnect separable union between pumpout

condenser and oil separator.

6.

Run pumpout compressor until desired

machine vacuum is reached.

7. Close valve 5 and reassemble union.

8. Stop compressor.

9. Remove jumper.

PRESSURIZING THE MACHINE (No refrigerant

in system)

1. Set purge valves per operation 4 on purge valve

operation plate.

Close valves 2, 4 and 10.

Open valves 1 , 3 , 5 , 6, 7 , 8, 9 and 1 1 .

Disconnect separable union in pumpout com

pressor suction line.

Operate pumpout compressor until desired

pressure is reached. Do not exceed test pressure

listed in Table 1.

Shut off pumpout compressor.

Reassemble union.

Return purge valves to Normal-Auto condition

when pressurizing is completed.

2

.

3.

4.

5.

6

.

7.

8

.

SEPARABLE UNION

Fig. 3 — Pumpout System Schematic (R-114 Units)

5