Table 4 — setting safety controls (cont), R^fiyc – Carrier 17CB User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 4 — Setting Safety Controls (cont)

SAFETY OR CONTROL DEVICE

SAFETY OR CONTROL DEVICE

STOP MACHINE, REMOVE JUMPERS AND PERFORM RE

MAINING CHECKS.

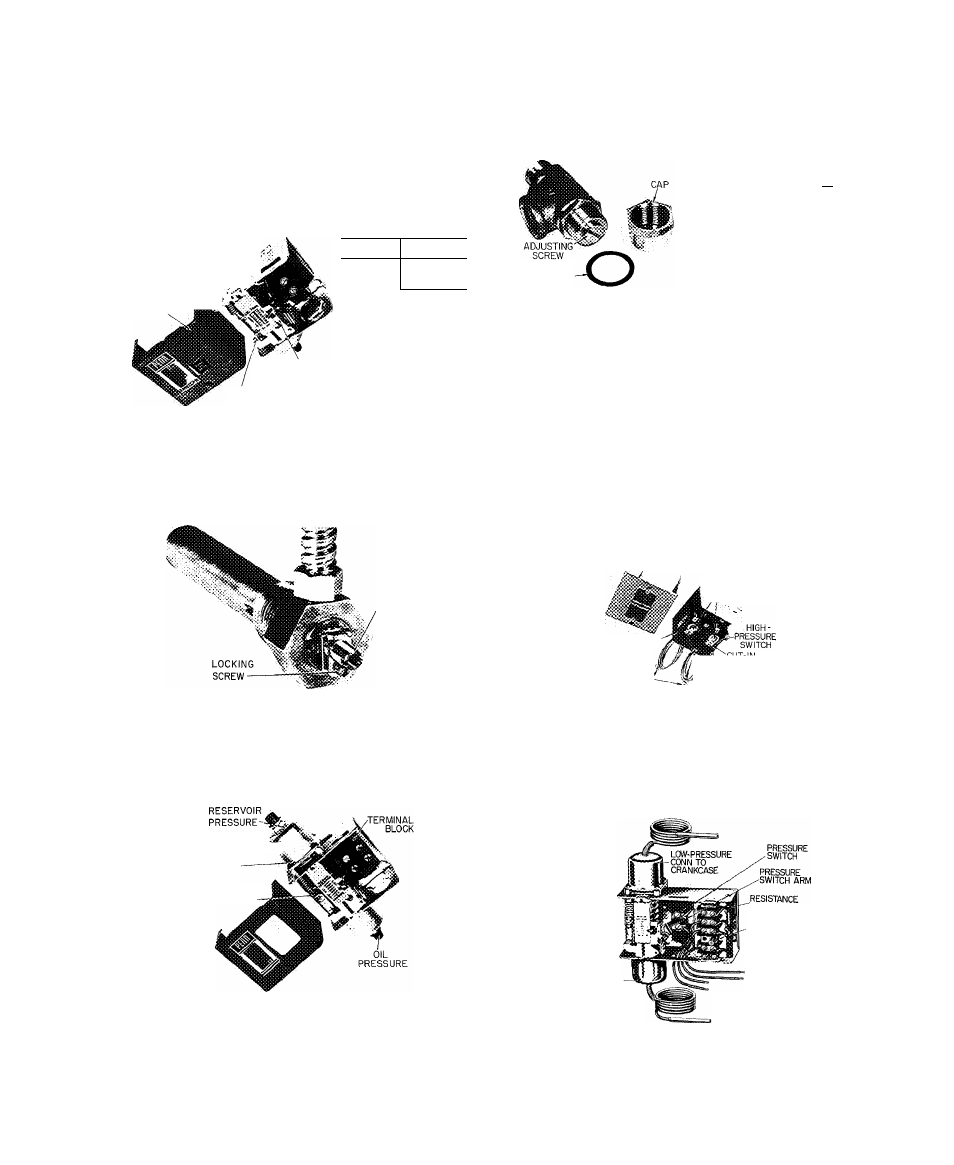

3. Condenser High-Pressure Cutout (Fig. 6 and 7).

CUTOUT ADJUSTM^T

COVER

REFRIG

SETTING

11

15 psig

114

45 psig

RESET

BUTTON

CUTOUT SCALE

The condenser high-pressure cutout is factory set to shut the

machine down when condenser pressure reaches setting listed.

Isolate the switch and check setting with a metered supply of air.

4. Oil Heater Thermostat (Fig. 2).

SCREW

Set the oil heater thermostat to maintain a minimum oil reservoir

temperature of 140 F at shutdown

5. Low Oil Pressure Cutout (Fig. 2).

RANGE

DIAL ADJUSTMENTT

î

:

REMOVE METAL

COVER

DIFFERENTIAL

Low oil differential pressure switch is factory set to open at 11 ± 1

psi and close at 15 ± 1 psi differential pressure Operate oil pump

manually Remove cap and gasket from regulating valve and loosen

locknut. Turn adjusting screw counterclockwise to lower oil

pressure to 11 psi differential If safety does not trip, turn range dial

clockwise until cutout occurs

6. Oil Pressure Regulating Valve (Item 20, Fig. 2).

R^FiyC

11

114

SETTING*

15 psid

1 5-20 psid

*Settings given are above

reservoir pressure

SEALING

GASKET

Remove cap and washer and loosen locknut Turn adjusting screw

clockwise to raise oil pressure.

7. Vane Speed Valve (Electronic Machine Only)

Angle valve is located between oil line to main bearing and "F" and

“G" solenoid valves (items 17 and 19, Fig. 2) Set valve at full open

position

8. Chilled Water Flow Switch

Field supplied and installed. Follow switch manufacturer's instruc

tions for adjustment and maintenance

9. Main Bearing Oil Temperature (item 11, Fig. 2)

During machine operation, gauge should read 150 to 165 F. Adjust

water flow thru oil cooler with plug cock (item 16, Fig 2). Do not

exceed 7 gpm or pressure drop of 5 psig. Do not exceed 100 psi

working pressure

10. Dual Pressurestat for R-114 Pump-Down Compressor

COVER

CUTOUT AND

CUT-IN PRESSURE

. ADJUSTMENT

LOW-PRESSURE

SWITCH

COMPRESSOR.

CONNECTIONS

\jp PRESSURE

l-ADJUSTMENT ONLY

CUTOUT PRESSURE

ADJUSTMENT ONLY

High-pressure switch to open on rise at 45 psig Low-pressure switch

to open on fall at 2 0 in. Hg vacuum.

Set high-pressure switch by operating compressor and throttling

pump-down condenser water while watching pressure gauge.

Set low-pressure switch by operating compressor and gradually

shutting suction valve while watching pressure gauge.

11. Oil Safety Switch for R-114 Pump-Down Compressor

HIGH PRESSURE

CONN TO

OIL PUMP DISCHARGE

MANUAL

RESET BUTTON

CONNECT IN

SERIES WITH

CONTROL CIRCUIT

(SEE WIRING

DIAGRAM)

CONNECT TO

II50R 230V SOURCE

(SEE WIRING DIAGRAM)

Contacts open on drop in oil pressure. Cutout 11-14 psi; cut-in

16-19 psi differential between pump discharge and compressor

suction

Preset switch with an external air source

11