A warning, Fig. 9—blower control center – Carrier 58PAV User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

-------------------FIELD 24-VOLT WIRING

—~ FIELD 115-, 208/230-, 460-VOLT WIRING

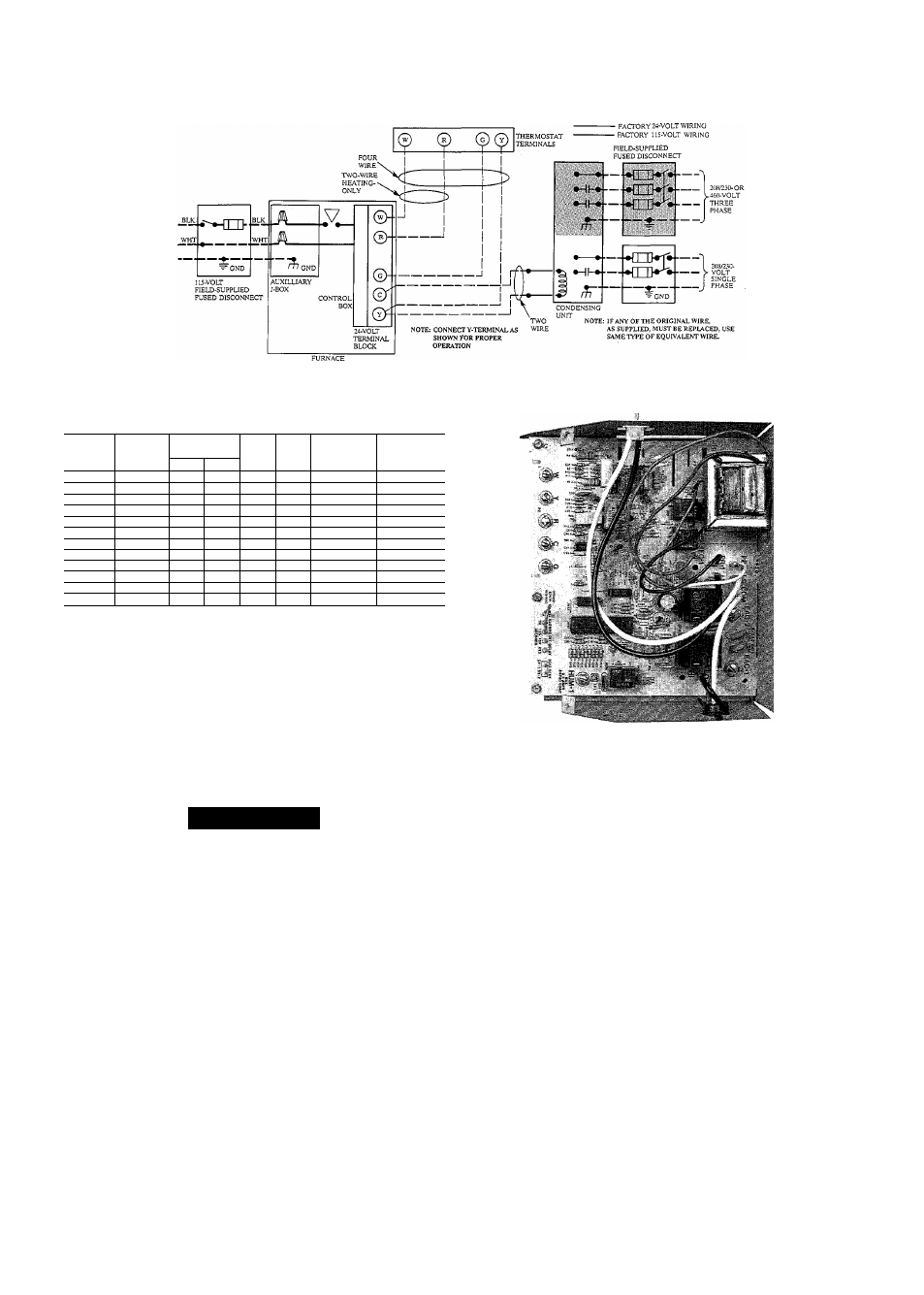

Fig. 8—Heating and Cooling Application Wiring Diagram

Table 5—Electrical Data

Furnace

Volts-

Operating

Max.

Min.

Max. Wire

Max. Fusef or

Size

Hertz-

Voltage Range

Unit

Wire

Length

HACR-Type

Phase

Max*

Min.*

Amps

Gage

Ftt

Ckt Bkr Amps

035-EC

115—60—1

127

104

6.7

14

53

15

035-GC

115—60—1

127

104

8.3

14

43

15

055-EC

115—60—1

127

104

7.1

14

50

15

055-GC

115—60—1

127

104

8.7

14

41

15

075-GC

115—60—1

127

104

9.0

14

40

15

075-JC

115—60—1

127

104

10.4

14

35

15

090-GC

115—60—1

127

104

7.9

14

45

15

090-JC

115—60—1

127

104

9.6

14

37

15

090-LC

115—60—1

127

104

14.4

12

40

20

110-JC

115—60—1

127

104

10.0

14

36

15

110-LC

115—60—1

127

104

13.3

12

43

20

125-LC

115—60—1

127

104

14.0

12

41

20

♦Permissible limits of the voltage range at which the unit will operate

satisfactorily.

tTime-delay fuse is recommended.

ifLength shown is as measured one way along wire path between unit

and service panel for maximum 2% voltage drop.

Make all electrical connections in accordance with the

National ElectriceJ Code ANSI/NFPA 70 and local codes or

ordinances that might apply. For Canadian installations, all

electrical connections must be made in accordance with

CSA C22.1 Canadian Electrical Code, or authorities having

jurisdiction.

A WARNING

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code, ANSI/

NFPA 70 and Canadian Electrical Code, CSA C22.1 or

local codes to minimize personal injury if an electrical

fault should occur. This may consist of electrical wire or

conduit approved for electrical ground when installed in

accordance with existing electrical codes. Do not use

gas piping as an electrical ground.

The auxihary junction box can be moved to the right-hand

side of the furnace when a right side power supply is

desired. Remove the two screws holding the auxihary junc

tion box. Mount the junction box on the right-hand side of

the furnace (holes have been predrüled in casing). The

blower door interlock switch must also be moved to the

right side of the furnace due to the length of the wiring har

ness. When moved, tuck the wiring harness behind the clip

provided to keep extra wire lengths out of the way.

NOTE;

Proper polarity must be maintained for 115-VAC

wiring. If polarity is incorrect, the microprocessor wiU shut

off gas flow shortly after the completion of ignition trial

period.

Fig. 9—Blower Control Center

B. 24-Volt Wiring

Make field 24-volt connections at the 24-volt terminal strip.

See Fig. 8. Connect terminal Y as shown in Fig. 8 for proper

cooHng operation. Use only AWG No. 18, color coded cop

per thermostat wire.

C. Accessory

1. Electronic air cleaner

Two screw terminals (EAC-1 and EAC-2) are provided

for electronic air cleaner connection. The terminals are

energized with 115-VAC, 1 amp maximum during

blower motor operation.

2. Humidifier

Screw terminals (HUM-1 and C) are provided for 24-

VAC humidifier connection. The terminals are ener-

, gized with 24-VAC, 0.5 amp maximum during heating

blower motor operation.

VII. VENTING

These instructions are to be used only for 58PAV Furnace

vent systems. These furnaces are equipped with induced-

combustion blowers, and are classified as Category I type

furnaces in accordance with ANSI/A.G.A. Z21.47 Central

Furnace Standards. Category I furnaces use nonpositive,

noncondensing vent systems, and may be connected to Hned

masonry chinmeys sized and installed per the National Fuel

Gas Code.