A warning, A caution – Carrier 58PAV User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Install another nut on other side of furnace base.

(Install flat washer if desired.)

4. Adjust outside nut to provide desired height, and

tighten inside nut to secure arrangement.

V. GAS PIPING

Gas piping must be installed in accordance with national

and local codes. Refer to the current edition of the National

Fuel Gas Code. Canada installations must be installed in

accordance with CAN/CGA.B149 Installation Codes, and all

authorities having jurisdiction.

The gas supply line should be a separate line running

directly from the gas meter to the furnace, if possible. Refer

to Table 4 for the recommended gas pipe size. Risers must

be used to connect to the furnace and the meter.

Table 4—Maximum Capacity of Pipe*

Nominal

Iron Pipe

Size

Ins.

Internal

Diameter

Ins.

Length of Pipe, Ft

10

20

30

40

50

1/2

0.622

175

120

97

82

73

3/4

0.824

360

250

200

170

151

1

1.049

680

465

375

320

285

1-1/4

1.380

1400

950

770

660

580

1-1/2

1.610

2100

1460

1180

990

900

*Cubic ft of gas per hour, for gas pressures of 0.5 psig (14 ins. wc) or less,

and a pressure drop of 0.5 in. wc (based on a 0.60 specific gravity gas).

Ref; Table C-4 NFPA 54-1988.

A CAUTION

If a flexible connector is required or allowed by the

authority having jurisdiction, black iron pipe shall be

installed at the gas valve and extend a minimum of 2-

ins. outside the furnace casing.

Piping should be pressure-tested in accordance with local

and national plumbing and gas codes before the furnace has

been attached. If the pressure exceeds 0.5 psig (14 in. wc),

the gas supply pipe must be disconnected from the furnace

and capped before the pressure test. If the test pressure is

equal to or less than 0.5 psig (14 in. wc), close the manual

shut-off valve located on the gas valve before the test. It is

recommended that the ground joint union be loosened

before pressure testing. After all connections have been

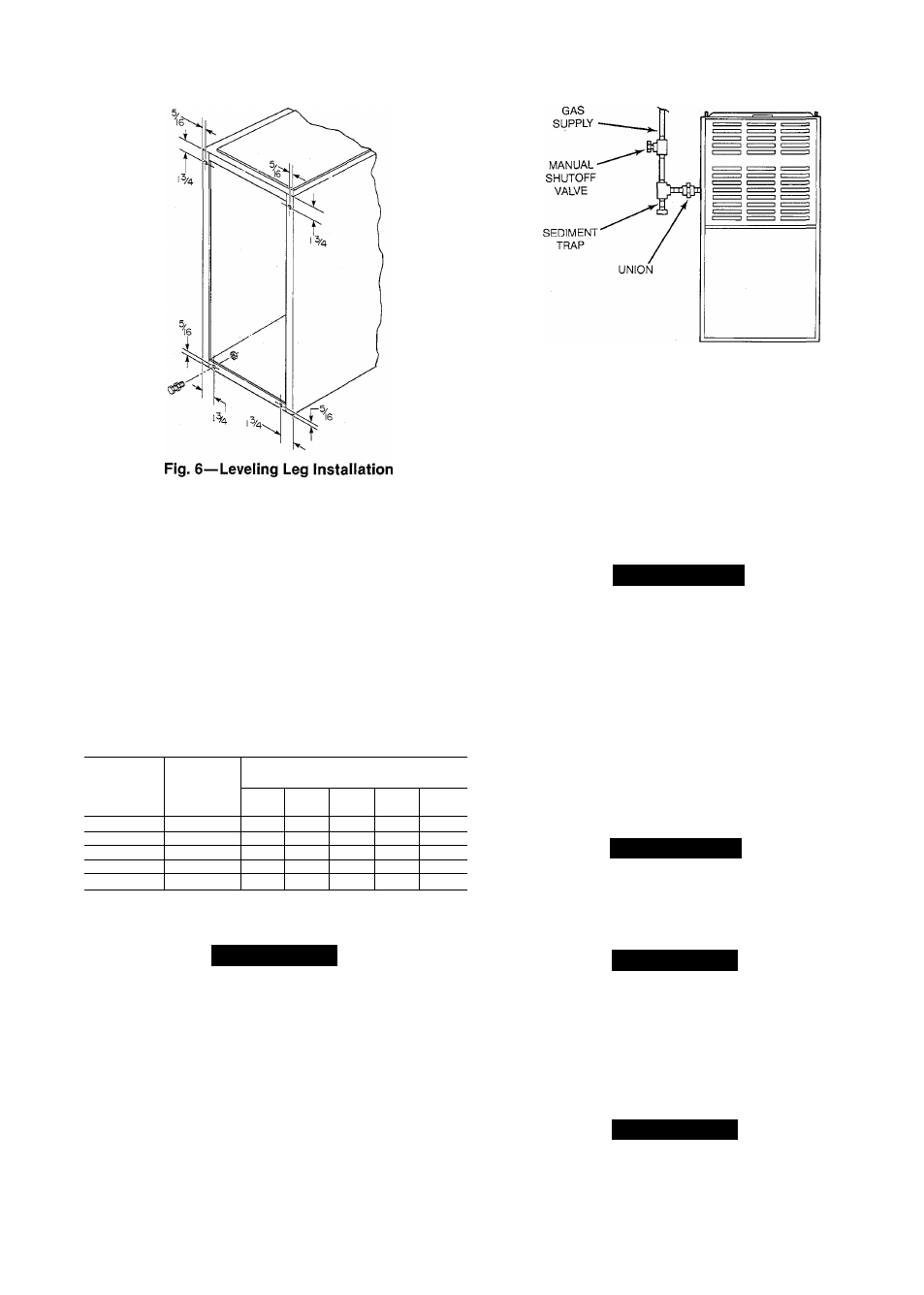

Fig. 7—Typical Gas Pipe Arrangement

made, purge the lines and check for leakage with regulated

gas supply pressure.

Install a sediment trap in the riser leading to the furnace.

The trap can be installed by connecting a tee to the riser

leading from the furnace. Connect a capped nipple into the

lower end of the tee. The capped nipple should extend below

the level of the gas controls. See Fig. 7.

Apply joint compound (pipe dope) sparingly and only to the

male threads of each joint. The compound must be resistant

to the action of propane gas.

A WARNING

Never purge a line into a combustion chamber. Never

use matches, candles, flame, or other sources of ignition

for the purpose of checking leakage. Use a soap-and-

water solution to check for leakage. A failure to follow

this warning can cause a fire, explosion, personal

injury, or death.

An accessible manual shut-off valve shall be installed

upstream of the furnace gas controls and within 6 ft of the

furnace. A 1/8-in. NPT plugged tapping, accessible for test

gauge connection, must be installed immediately upstream

of the gas supply connection to the furnace and downstream

of the manual shut-off valve. Place ground joint union

between the gas control manifold and the manual shut-off

valve.

A WARNING

Use the proper length of pipes to avoid stress on the

gas control manifold. A failure to follow this warning

can cause a gas leak resulting in a fire, explosion, per

sonal injury, or death.

A CAUTION

Use a backup wrench when connecting the gas pipe to

the furnace to avoid damaging gas controls.

VI. ELECTRICAL CONNECTIONS

A. 115-Volt Wiring

Refer to the unit rating plate or Table 5 for equipment elec

trical requirements. The control system requires an earth

ground for proper operation.

A CAUTION

Do not connect aluminum wire between disconnect

switch and furnace. Use only copper wire.