Carrier 58PAV User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

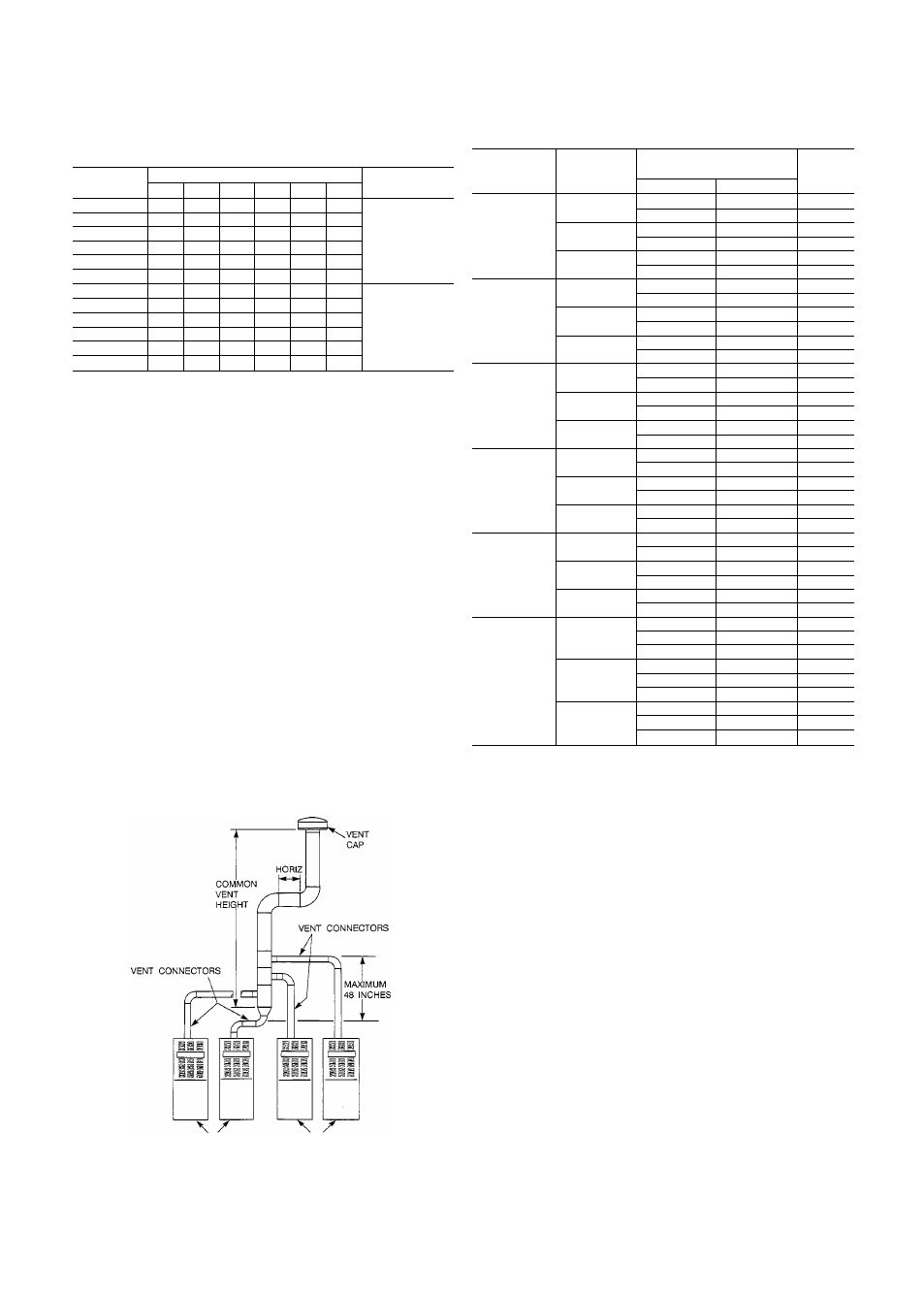

Table 11—Dedicated Type B-1 Vent For

58PAV125-LC Maximum

Horizontal Length Allowed (Ft)

Table 12—Common Venting Of Furnaces

(Typicai instaliation)

Height

Number of 90° Elbows

Vent

Pipe

0

1

2

3

4

5

5

NA

NA

NA

NA

NA

NA

5-IN.

DIAMETER

10

0

10

10

NA

NA

NA

15

0

15

15

15

15

15

20

0

20

20

20

20

20

25

0

25

25

25

25

25

30

0

30

30

30

30

30

5

0

5

5

5

NA

NA

6-IN.

DIAMETER

10

0

10

10

10

10

10

15

0

15

15

15

15

15

20

0

20

20

20

20

20

25

0

25

25

25

25

25

30

0

30

30

30

30

30

NA—Not allowed. Condensation

could occur.

or positive pressure in vent system

C. Venting Tables For Common Vented Furnaces (two,

three, or four 58PAV Furnaces)

The following information refers to installations where two,

three, or four 58PAV Furnaces are common vented into a

single vent system. Do not connect more than four 58PAV

Furnaces into a common vent system. See Fig. 12. Table 12

data is for a vent system where all the furnaces are the same

size. For common vent apphcations using various sizes of

58PAV Furnaces, contact your Distributor or Dealer for

more information.

To determine the proper common vent size, total the heat

input of all the apphemces to be connected to the vent sys

tem, next select the smallest vent size which wUl meet that

rated input.

NOTE:

A listed single-wall to T3?pe B-1 vent adaptor is

required to connect single-wall vent connectors to the com

mon vent.

1. Vent connectors should be as short and direct as possi

ble, and should be made of Type B-1 double-wall vent

pipe or insulated single-wall vent pipe.

2. Vent connectors shall be sized using dedicated venting

table in Section B of this publication. The length of hor

izontal run used in the vent connector and vent must

never exceed the height of the common vent.

FURNACE

A89018

58PAV

Size

Number

of

Furnaces

Common Vent Height (Ft)

Vent

Dia

(Ins.)

Minimum

Maximum*

035-EC

or

035-GC

2

8

40

5

6

40

6

3

14

40

5

8

40

6

4

14

40

6

8

40

7

055-EC

or

055-GC

2

14

40

5

8

40

6

3

14

40

6

8

40

7

4

14

40

7

10

40

8

075-GC

or

075-JC

2

10

40

6

8

40

7

3

14

40

7

8

40

8

4

14

40

8

10

40

9

090-GC,

090-JC,

or

090-LC

2

14

40

6

10

40

7

3

10

40

8

8

40

9

4

10

40

9

10

40

10

110-JC

or

110-LC

2

14

40

7

8

40

8

3

10

40

9

8

40

10

4

16

40

9

10

40

10

125-LC

2

10

40

7

6

40.

8

6

40

9

3

14

40

8

8

40

9

8

40

10

4

18

40

8

14

40

9

10

40

10

*For applications requiring

tion other than specified,

information.

vent heights greater than 40 ft, or

contact your Distributor or Dealer

combina-

for more

apart

Fig. 12—Common Venting Of Furnaces

(Typicai installation)

3. Vent connectors should be spaced at least 1 ft

when entering the common vent system.

4. Insulated vent connectors may be required for certain

applications. See Sections A.5. and A.6. for additional

information.

5. For multi-story installation, refer to Appendix G of

National Fuel Gas Code or Canadian standards CAN/

CGA.B149 for additional information in sizing the com

mon vent. Individual vent connectors should be sized

per the dedicated appliemce tables shown in Section B.

D. Venting Tables For Common Vents (One 58PAV

Furnace and Gas Hot Water Heater)

The information in this section refers to the installation of a

common vent serving a 58PAV Furnace and a gas hot water

heater. Tables 13 and 14 use typical hot water heater input

rates of 40,000 Btuh or 50,000 Btuh. Refer to the water

heater rating plate for input ratings of the installed

equipment.

1. Size common vent and vent connector lengths using

Tables 13 and 14.

2. Vent connectors should be as short and direct as

possible.

3. Size gas water heater vent connector per National Fuel

10