A warning – Carrier 58PAV User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

total input for all equipment within the confined space.

For Example:

58PAV Furnace

Input Btuh

Free Area per Opening

(square ins.)

Round Pipe

(ins. dia)

44,000

22.0

6

66,000

33.0

7

88,000

44.0

8

110,000

55.0

9

132,000

66.0

10

154,000

77.0

10

When ducts are used, they must be of the same cross sec

tional area as the free area of the openings to which they

connect. The minimum dimension of rectangular ducts must

not be less than 3-ins. See Fig. 3.

A WARNING

Do not install the furnace on its back; safety control

operation will be adversely affected. Never connect

return-air ducts to the back of the furnace. A failure to

follow this warning can cause a fire, personal injury, or

death.

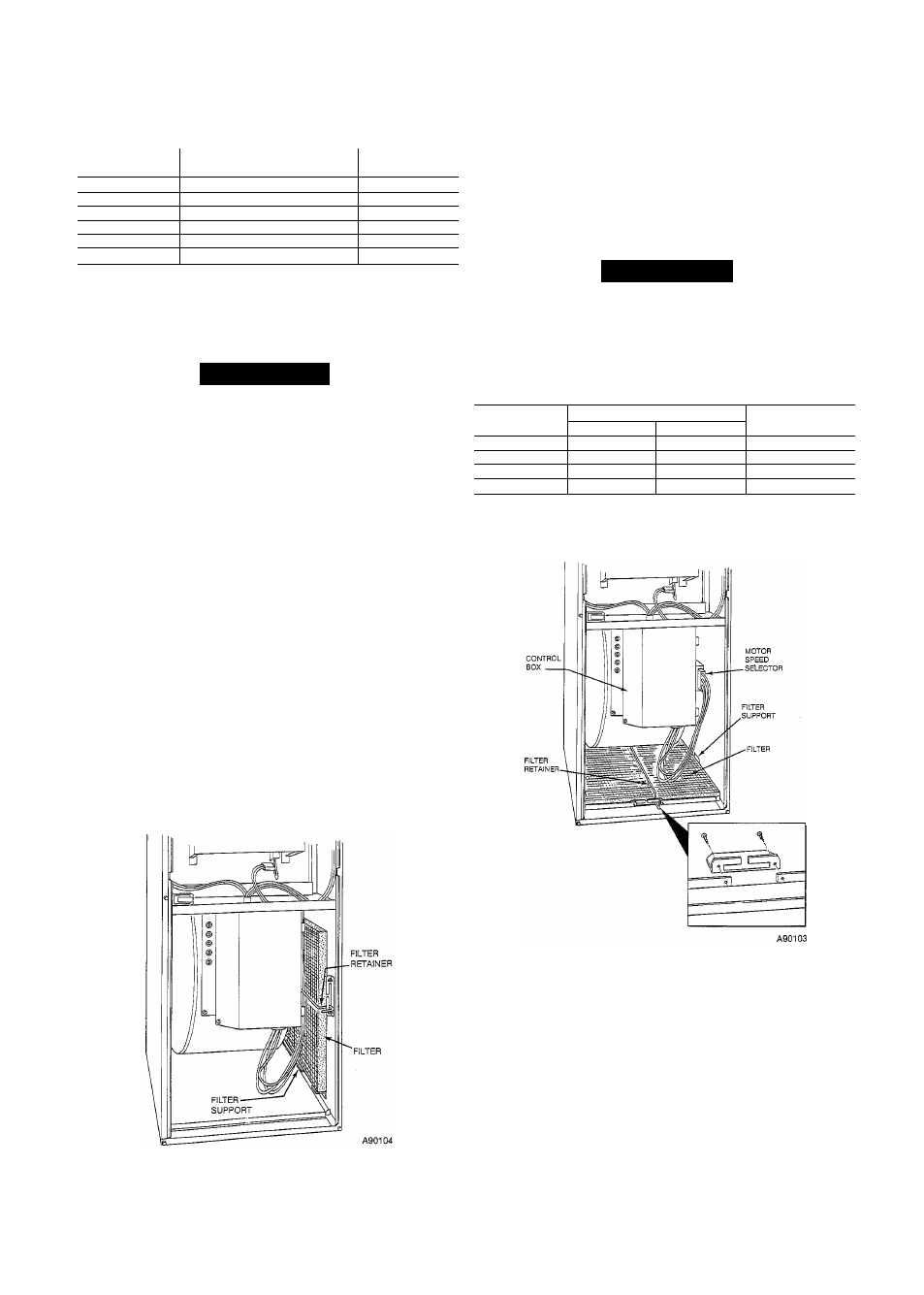

III. FILTER ARRANGEMENT

The factory-supphed filter(s) is shipped in the blower com

partment. Deterrnine location for the filter and move filter

retaining hardware, if necessary, before attaching the

return-air duct. After the return-air duct has been connected

to the furnace, install the filter(s) inside the furnace blower

compartment. See Fig. 4 for side return apphcation and Fig.

5 for bottom return application.

A bottom closure panel is factory-installed in the bottom of

the furnace. When bottom return inlet is desired, remove

and discard the enclosure panel.

Filter retaining brackets, supports, and retainers are fac

tory assembled and shipped installed for side return appUca-

tion, with one set of all required hardware provided. See Fig.

4.

For bottom return appHcations, remove the brackets

(front and back) and supports from each side. The back

bracket(s) are installed in the rear of the furnace casing

(dimples are provided to mark mounting screw locations).

The front bracket(s) are installed on the bottom front plate

as shown in Fig. 5, once the bottom enclosure has been

removed. Rotate filter supports 180 degrees so filter will

rest on support emd reinstall. (Do not reinstall in 17-1/2-in.

casing.) Install the filter retaining rod (small U-shaped end)

in the rear bracket, and the front of the filter retainer rod as

shown in Fig. 5. Two sets of hardware are needed for fur

naces in 24-1/2-in. casings using one filter for bottom return.

All hardware is provided for filter installation.

A WARNING

Never operate unit without a filter or with filter access

door removed. A failure to follow this warning can

cause a fire, personal injury, or death.

Table 3—Filter Information

Furnace

Fiiter Size*

Fiiter

Casing Width

Side Return

Bottom Return

Type

14-3/16

(1)16x25x1

(1)14x25x1t

Cleanable

17-1/2

(1)16x25x1

(1)16x25x1t

Cleanable

21

(1)16x25x1

(1)20 x 25x1t

Cleanable

24-1/2

(2)16x25x1

(1)24 x 25x1t

Cleanable

*Filter can be field-modified by cutting to the desired size. Aiternate sizes

can be ordered from your Distributor or Deaier.

fFactory provided with the furnace.

Fig. 4—Side Filter Arrangement

Fig. 5—Bottom Filter Arrangement

IV. LEVELING LEGS (If Required)

When the furnace is used with side inlet(s), and leveling legs

are required, refer to Fig. 6, and install field-supplied

corrosion-resistant 5/16-in. machine bolts and nuts.

NOTE;

The maximum length of the bolt should not exceed

1-1/2 ins.

1. Lay furnace on its back, locate and drill 5/16-in. diame

ter hole in each bottom corner of furnace as shown in

Fig. 6.

2. Install nut on bolt and install bolt and nut in hole.

(Install flat washer if desired.)