Fig-3, R~hn – Carrier 58PAV User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I

Combustion air requirements are determined by whether

the fiunace is in an UNCONFINED or CONFINED space.

A confined space is a space whose volume is less than 50

cubic ft per 1000 Btu per hour of the total output rating for

aU appliances installed in that space.

A. Unconfined Space

An unconfined space must have at least 50 cubic ft for each

1000 Btuh of input for all the appliances (i.e. furnaces,

clothes dryer, water heaters, etc.) in the space.

For Example:

58PAV Furnace

Input Btuh

Minimum Sq Ft

with

7-1/2 Ft Ceiling

44,000

293

66,000

440

88,000

587

110,000

733

132,000

880

154,000

1026

If the unconfined space is of unusually tight construction,

air for combustion and ventilation MUST come from either

the outdoors or spaces freely communicating with the out

doors. Combustion and ventilation openings must be sized

the same as for a confined space. A minimum opening hav

ing a total of not less than 1 square in. per 5000 Btuh of

total input rating for all equipment must be provided.

Return air must not be taken from the room, unless an equal

or greater eimount of air is supplied to the room.

B. Confined Space

A confined space MUST have two permanent openings, one

within 12-ins. of the ceiLing, and the other within 12-ins. of

the floor. See Fig. 2.

NOTE:

In deterniining the free area of an opening, the

blocking effect of the louvers, grilles and screens must be

considered. If the free area of a louver or grille design is

unknown, it may be assumed that wood louvers have a 20

percent free area and metal louvers or grilles have a 60 per

cent free area. Screens, when used, must not be smaller than

1/4-in. mesh. Louvers and grilles must be constructed so

they cannot be closed.

The size of the openings depend upon whether the air comes

from inside or outside of the structure.

SUPPLY

AIR

r~Hn

VENT TO ROOF

12 MAX

^ 1 SQ INCH

PER 1000

I BTUH*

INTERIOR

HEATED

SPACE

-6 MIN

(FRONT)

A89012

♦Minimum opening size is 100 square ins.

tMinimum of 3 ins. when type-B vent is used.

Fig. 2

1. All air from inside the structure

Each opening MUST have at least 1 square in. of free

area per 1000 Btuh of the total input for all equipment

within the confined space, but not less than 100 square

ins. per opening. See Fig. 2.

For Example:

58PAV Furnace

Input Btuh

Free Area per Opening

(square ins.)

44,000

100

66,000

100

88,000

100

110,000

110

132,000

132

154,000

154

If the building is of unusually tight construction, a perma

nent opening directly communicating with the outdoors

shall be provided. This opening shall have a minimum free

area of 1 square in. per 5000 Btuh of total input rating for

all equipment in the enclosure.

If the furnace is installed on a raised platform to provide a

return air plenum, and return air is taken directly from the

hallway or space adjacent to the furnace, aU air for combus

tion must come from outdoors.

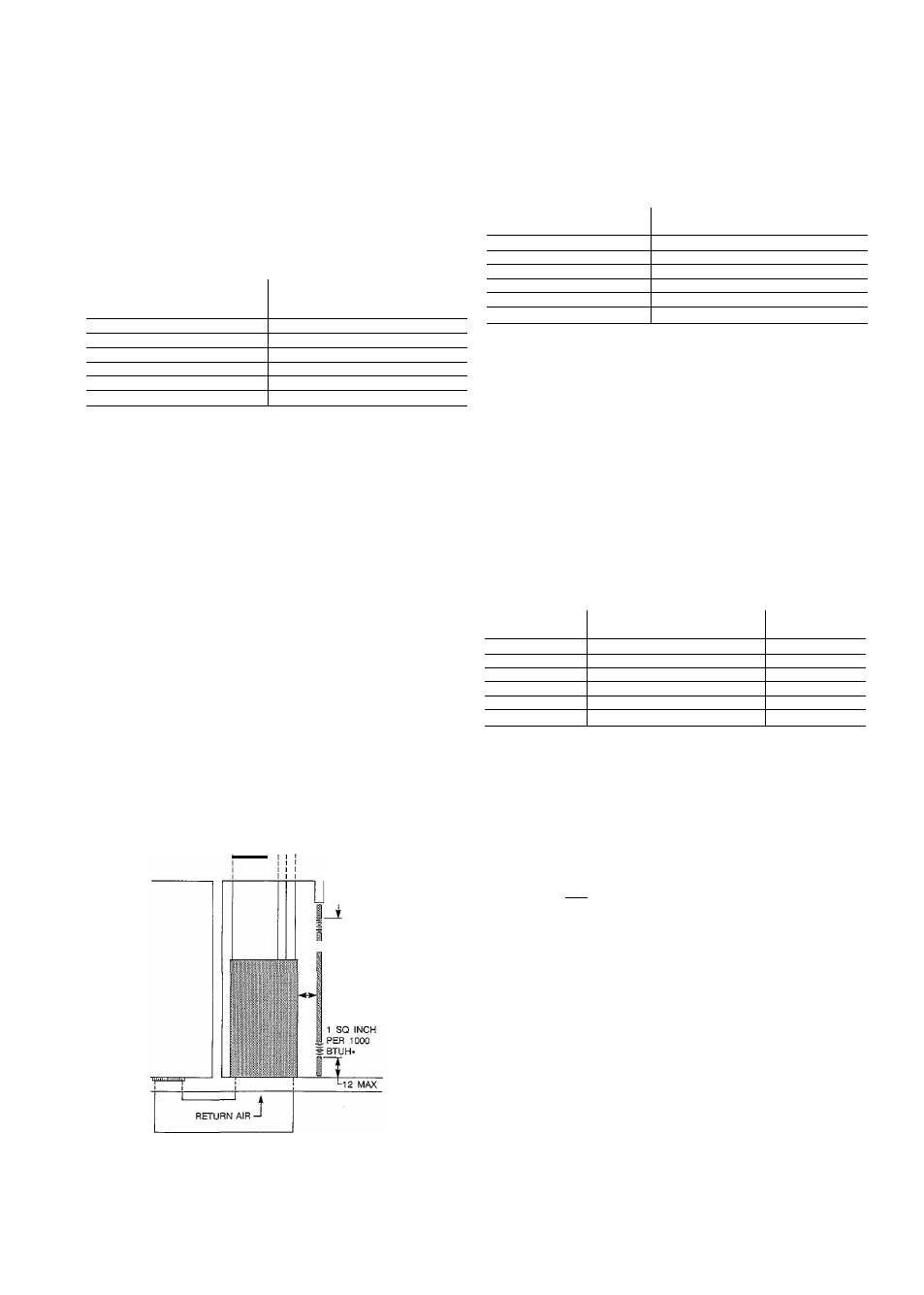

2. All air from outdoors

a. If combustion air is taken from outdoors through

vertical ducts, the openings and ducts MUST have

at least one square inch of free area per 4000 Btuh

of the total input for aU equipment within the con

fined space. See Fig. 3.

For Example:

58PAV Furnace

input Btuh

Free Area per Opening

(square ins.)

Round Pipe

(ins. dia)

44,000

11.0

4

66,000

16.5

5

88,000

22.0

6

110,000

27.5

6

132,000

33.0

7

154,000

38.5

7

b. If combustion air is taken from the outdoors through

horizontal ducts, the openings and ducts MUST have

at least one square in. of free area per 2000 Btuh of the

DUCTS

TO ROOF-

1 so INCH PER

4000 BTUH

I'. ".I

MAX 12

1 SQ INCH PERT

2000 BTUH

DUCTS TO

OUTS DE

1 SQ INCH PER

2000 BTUH ^

MAX 12

SUPPLY

D

AIR

A A VENT

T

TO ROOF

A

RETURN AIR

j

i

2 MAX

1 SQ INCH

,^PER 4000

BTUH

DUCT

TO OUTSIDE

USE ANY OF THE FOLLOWING

COMBINATIONS

OF

OPENINGS:

A&B C&D D&E

A89013

Fig-3