Jk caution, A caution, Caution – Carrier 38QE User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A89059

(Top)

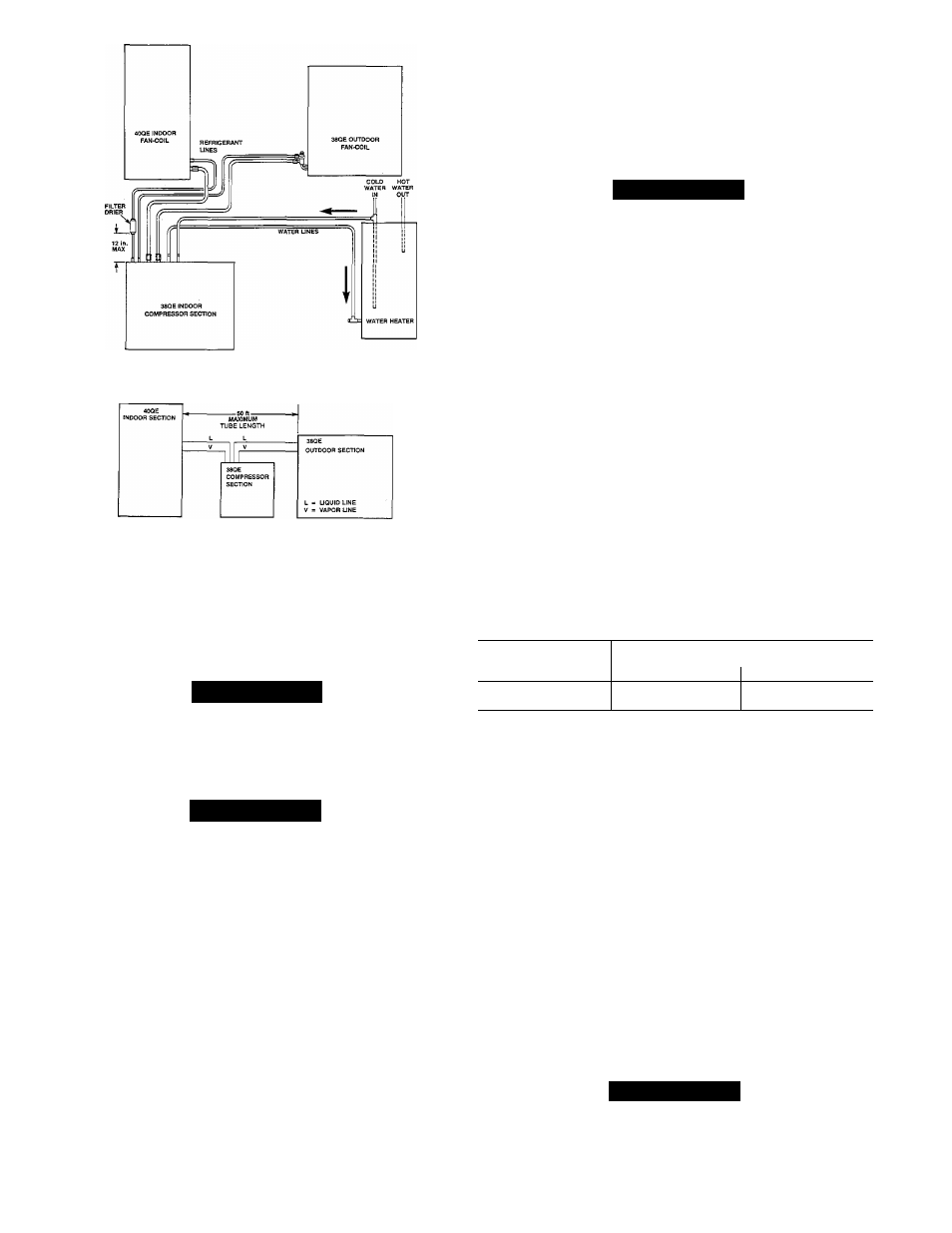

Fig. 5—38QE/40QE System Piping Schematic

A89059

(Bottom)

Fig. 6—Maximum Refrigerant Line Length

4. After wrapping the service valve with a wet cloth, the

tubing set can be brazed to the service valve using

either silver bearing or non-silver bearing brazing

material. Consult local code requirements.

Outdoor Fan Coil Section

Jk

CAUTION

A brazing shield MUST be used when tubing sets are

being brazed to the service valves to prevent damage to

the painted unit surface.

A

CAUTION

To avoid damage while brazing, service valves must be

wrapped with a heat-sinking material such as a wet

cloth.

Both the liquid emd vapor lines require sweat connections.

Use proper equipment and safety precautions when making

the sweat connection. The service valves on this unit are

both front and backseating. The service port does not con

tain a Schrader fitting. Do not attempt to connect manifold

until valve is fully backseated.

Service valves are closed from factory and ready for braz

ing. After wrapping the service valve with a wet cloth, the

tubing set can be brazed to the service valve using either sil

ver bearing or non-silver bearing brazing material. Consult

local code requirements.

Outdoor units contain correct system refrigerant charge for

operation with indoor unit of the same size when connected

by 25 ft of field-supplied or factory accessory tubing. Check

refrigerant charge for maximum efficiency (see Refrigerant

charging).

Indoor Fan Coil Section

The liquid and vapor tube fittings are flare and compatible,

respectively on the 40QE units. Use proper equipment and

safety precautions when making the flare connections.

Refer to the 40QE Installation Instructions.

Step 10—

Install Domestic Hot Water Piping

A CAUTION

Use only water piping, fittings and brazing material

that are suitable for Potable Water systems when con

necting the heat pump to the household water system.

Consult local codes.

The compressor section and domestic water heater should

be located as near as possible to each other. Total length of

interconnecting water piping between the compressor sec

tion and water heater should not exceed the lengths shown

in Table 3. The number of bends and pipe fittings should be

kept to a minimum. The use of shut-off valves in the water

lines between the domestic water tank and the compressor

section are not recommended as they may adversely affect

the system performance. (If valves are used, use only Ball or

Gate type). However compliance with local codes should be

followed. Failure to insulate pipes will result in performance

degradation..

Domestic Water Heating Tank

The 38QE can be installed with a conventional electric

water heater or with a gas water heater system. The basic

installation procedures are the same. However in the instal

lation with the gas water heater an insulated preheat tank

Table 3—Recommended Water

Piping Size

PIPE SIZE

ALLOWABLE TOTAL

ALLOWABLE TOTAL

PLUS

PIPING LENGTH (Ft)t

PIPING ELBOWS

1/2" nom (5/8" OD)

20

6^

3/4" nom (7/8" OD)

50

6**

♦Length can increase by 1.6 ft for each elbow less than 6.

♦♦Length can increase by 2.0 ft for each elbow less than 6.

tTotal length of cold and hot water pipes.

must be used. The preheat tank is essentially an electric

water tank without the electric heating elements.

Installation of the 38QE with a conventional electric water

heater is shown in Fig. 7a. Installation with a gas water

heater and preheat tank is shown in Fig. 7b.

Tank Water Temperature Sensor

The connection of the water heating lines to the tank

includes the installation of the tank water temperature sen

sor. The tank water temperature sensor is located within the

drain fitting of the tank. The fitting location is shown in

Fig. 7a,b. The detail for instaUing the sensor is shown in

Fig. 8.

Water connection tubes on the 38QE compressor section are

identified in Fig. 4. The two tubing stubs require field-

supplied sweat couplings or reducing couplings for connec

tion to water lines.

A CAUTION

A brazing shield must be used when tubing and fittings

are being brazed to the water stub tubes to prevent

damage to the painted unit surface.