Carrier 38QE User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

If the thermostat displays a hardware, software, heat pump,

or fan coil error code (HF,SF,HP or FC followed by a two

digit number), refer to the HydroTech 2000 Start-up and

Service Manual for further instruction on how to isolate and

clear system problems.

At initial start-up, thermostat(s) and bypass controller func

tions must be manually configured. This may be accom-

pHshed per the instructions located under the thermostat

cover with addressing exceptions as Hsted below:

NOTE: Be sure to correctly configure system for a variable

speed system and single- or multiple-zone application as

detailed in the instructions for rotary switch position F8, F9

and F13.

The proper configuration, programming and setup for

single- and multiple-zone installations are described here:

1. Address numbers 1 thru 2 are reserved for the 38QE

controls. No other devices can use address 1 thru 2. Be

sure the 38QE compressor section control module is set

to address 1 and the 40QE fan section control module

is set to address 2.

2. The monitor thermostat used for single-zone applica

tions should use address 3.

3. For multiple-zone apphcations the monitor thermostat

MUST BE addressed to the highest number followed

by the bypass controller (required) and then the slave

thermostats in any order (example: monitor thermostat

is address 6, bypass controller is address 5, zone 2

slave thermostat is address 4, zone 3 slave thermostat

is address 3.)

4. Power to indoor unit must be cycled after any change

to monitor thermostat address.

After all device features have been set or checked, return all

rotary switches to position 0 then, start-up and check the

operation of the 38QE variable speed system. Refer to

HydroTech 2000 Start-up and Service Manual.

To check the configm-ation:

1. Power up the thermostat.

2. Remove the thermostat cover.

3. Turn the rotary switch to the position indicated in

Table 5.

4. Check that the configuration settings are correct.

After the configuration values are correctly set:

1. Turn the rotary switch to position “0”.

2. Replace the thermostat cover.

These configuration items are the minimum required to get

the system running. There are many other options and fea

tures available through the remaining configuration set

tings. Refer to the Parker Reference Manuals for a complete

description and correct use of these additional features.

Step 17—Adjust Refrigerant Charge

38QE refrigerant charge adjustment or recharge must be

made by weighing-in the proper amount of refrigerant. Serv-

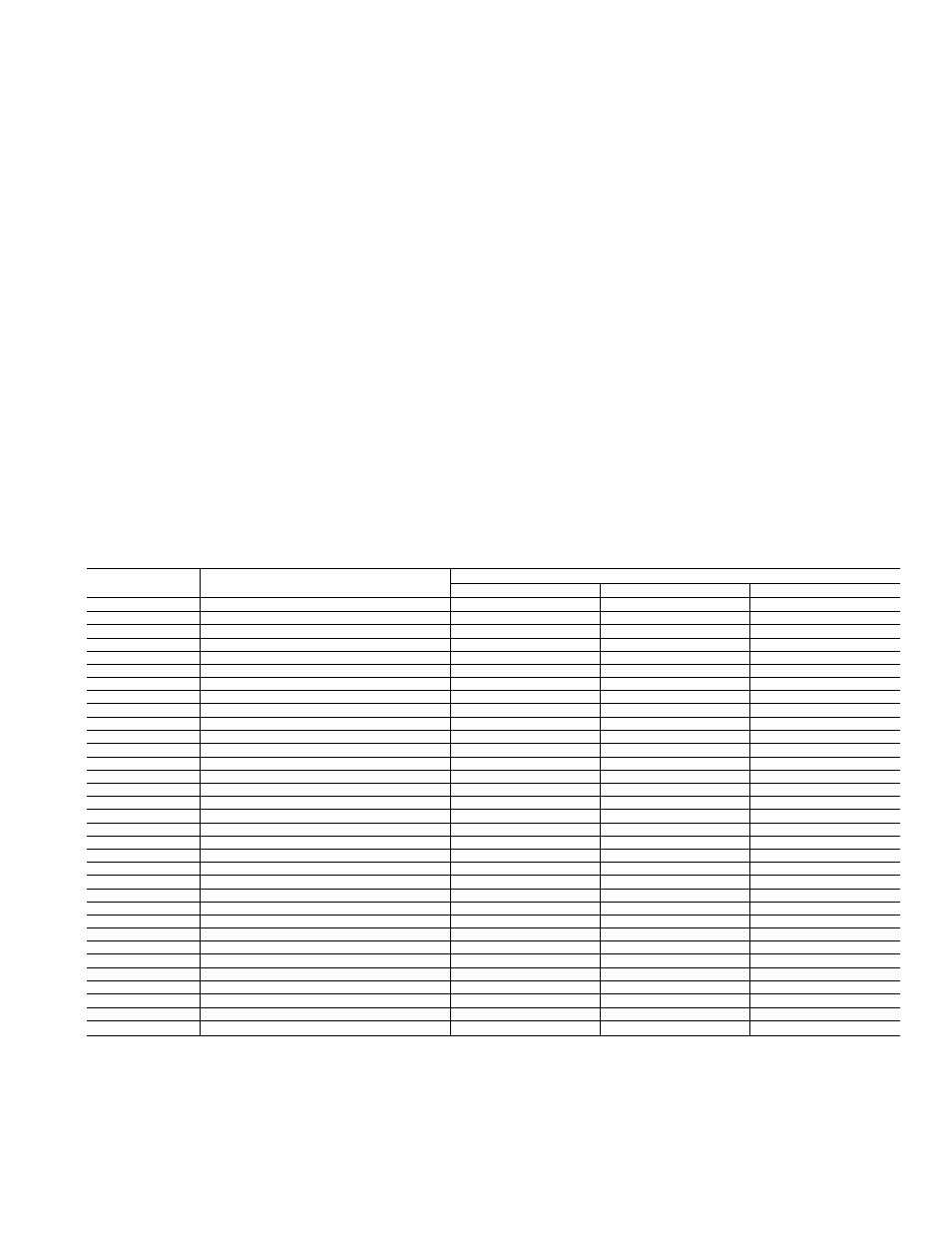

Table 5—Carrier/Parker HT2000 Home-Zone® Thermostat Configuration

ROTARY SWITCH

DISPLAY

POSITION

ROTARY SWITCH SETTING

FACTORY SET.

SINGLE ZONE

MULTIPLE-ZONE

0

COMFORT SETPOINTS

74 74

74 74

74 74

1

DEVICE ADDRESS

3

3

m*

2

SETBACK OVERRIDE TIME LIMIT

60

60

60

3

SETBACK SETPOINTS

85 65

85 65

85 65

4

DAMPER MAXIMUM OPEN POSITION

15

15

15

4

DAMPER VENTILATION POSITION

05

05

05

5

ZONE TEMP. SENSOR CALIBRATION

*

*

*

6

SUPPLY AIR TEMP. SENSOR CALIBRATION

*

*

*

7

COMMUNICATION CHECK

OFF

OFF

OFF

8

PRESSURE SENSOR ERROR CORRECTION

*

*

*

9

MAXIMUM PRESSURE SETPOINT

100*

100*

100*

A

HUMIDITY SETPOINT

50

50

50

B

SYSTEM MODE DEMAND/LARGE DEMAND

1

1 4

1 4

c

VARIABLE SPEED EQUIPMENT CONFIG.

*

«

*

D

NOT USED

BLANK

BLANK

BLANK

E

NOT USED

BLANK

BLANK

BLANK

F1

HTG./CLG. TIMEGUARD OVERRIDE

OFF

OFF

OFF

F2

CELSIUS TEMPERATURE DISPLAY

OFF

OFF

OFF

F3

ERROR CODE DISPLAY

ON

ON

ON

F4

2400 BAUD RATE

ON

ON

ON

F5

HEAT PUMP SYSTEM

ON

ON

ON

F6

LOCAL OUTSIDE AIR TEMP. SENSOR**

OFF

OFF

OFF

F7

DX COIL TEMPERATURE SENSOR

OFF

OFF

OFF

F8

MULTIPLE ZONE SYSTEM

OFF

OFF

ON

F9

VARIABLE SPEED EQUIPMENT

ON

ON

ON

F10

LOCAL HUMIDITY SENSOR

OFF

OFF

OFF

F11

EFFICIENCY OPERATING MODE

OFF*

OFF*

OFF*

F12

ALTERNATE INFORMATION DISPLAY

OFF

OFF

OFF

F13

HIGH/LOW TEMPERATURE LIMITS

OFF

OFF

OFF

F14

AUTO FAN OFF FOR HEAT

ON

ON

ON

F15

TEMPERATURE TREND STAGING

ON

OFF

OFF

F16

SETBACK LOCKOUT

OFF

OFF

OFF

FI 7

BYPASS CONTROLLER

OFF

OFF

ON

*VSE PARAMETERS ARE USED TO CONFIGURE OR TROUBLESHOOT THE VARIABLE SPEED SYSTEM. FOR DETAILS, REFER TO THE START-UP

AND SERVICE MANUAL FOR THE COMPRESSOR BEARING SYSTEM.

NOTE: ADDRESS THERMOSTAT FOR MULTIPLE-ZONE OPERATION AS FOLLOWS: SLAVE

2 ADDRESS

= m-3

MONITOR ADDRESS

= m

I

BYPASS CONTROL ADDRESS =

m-1

I

SLAVE 1 ADDRESS

= m-2

SLAVE x ADDRESS

= 3

X =

NO. OFZONES-1

4 ZONES MAX. (MONITOR -I- SLAVES)

(REFER TO COMPRESSOR UNIT INSTRUCTIONS

FOR OTHER ZONING LIMITATIONS)

13