Ob&îïêctéd betwëèù tbe ìkmti;|ìiiì – Carrier 58GS User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

m

OVERHEAT FUSE LINK — The furnace is

equipped with a fusible element to protect against

overtemperature conditions in the vestibule that can

result from inadequate combustion air supply.

WARNÌNG: 0o

rtot

bjpass tììc fusible element

4ÏÎÉ:

ob&îÏÊCtéd betwëèù tbe ÌKmti;|ÌIIÌ

lì

ii;i©pe}3Sÿi)Sîaife^:

the combiìi!tìou: air soppìy:..

etemeut vwth au idejRîicaîpari;

HYïOLFm.

m

REGULATOR

ADJUSTMENT

PILOT

ADJUSTMENT

PILOT

TUBE

CONNECTION

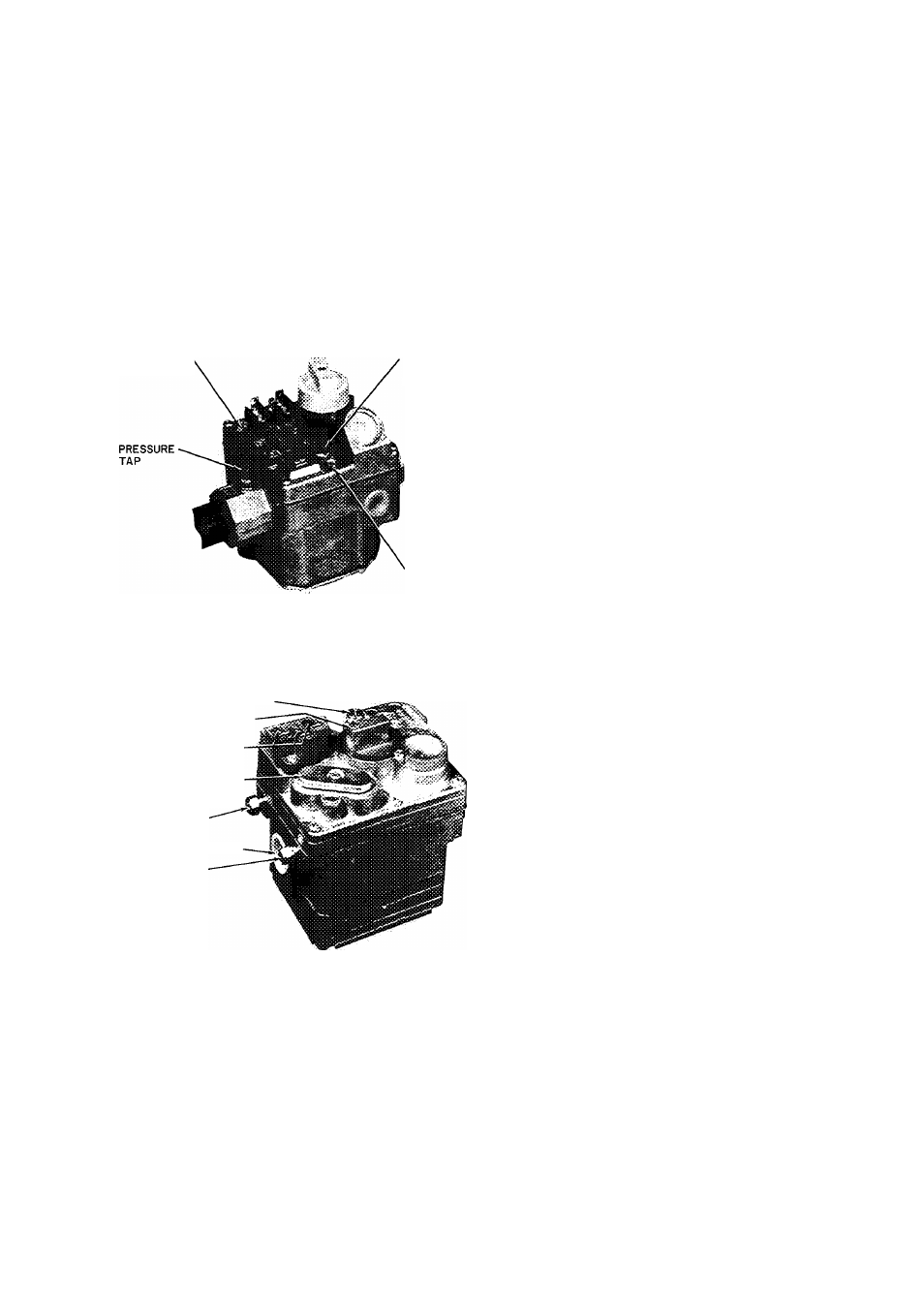

Fig. 10 - BDP 646AW Gas Valve

PILOT ADJUSTING SCREW CAP

MANUAL SHUTOFF VALVE

AND PILOT COCK

LOW VOLTAGE

CONNECTIONS

REGULATOR ADJUSTING

COVER (ADJUST "Hi"

SIDE SCREW)

PILOT GAS LINE

CONNECTION

MAIN GAS CONNECTION

PRESSURE TAP

Fig. 11 — Essex 242 Gas Valve

COOLING — When the thermostat calls for cool

ing, power from the transformer energizes the

blower relay coil, closing its normally open contacts,

and energizing the blower motor on its cooling

speed. It continues to operate until the thermostat

is satisfied.

When the thermostat is satisfied, the circuit to

terminal (G) is broken, de-energizing the blower

relay coil which, in turn, opens its contacts, stopping

the blower motor.

AUTOMATIC GAS CONTROL VALVE The

automatic gas valve controls the flow of gas to both

pilot and main burners. All models have the manual

valve built into the automatic valve body. The

manual valve has only 2 positions: OFF and ON. It

does not have an intermediate position for pilot gas

flow only.

To shut off the gas manually, turn knob from ON

to OFF position. When in OFF position, the main

burners and the pilot flame are extinguished.

Starting Procedure

— Check to be sure that all

connections have been properly made, then pro

ceed as follows:

Use the procedure outlined on the Lighting In

struction Plate attached to the furnace. See Se

quence of Operation and perform the following

additional steps:

1. If supply line was not purged before connecting

furnace, it will be full of air. It is recommended

that pilot supply line be disconnected at pilot

shutoff valve or main gas valve, and supply line

be allowed to purge until odor of gas is detected.

Never purge gas lines into combustion chamber.

Immediately upon detection of gas odor, re

connect pilot supply tube. Allow 5 minutes to

elapse before lighting furnace.

2. Pilot flame should be soft blue in color.

For natural gas controls, flame should be of

sufficient length to provide good impingement

on element of pilot. Flame should extend upward

between carryover ports of 2 adjacent burners.

3. Pilot adjusting screw is located on main gas

valve, or pilot shutoff valve.

a. Remove capscrew; turn pilot gas full on and

adjust adjusting screw until desired appear

ance is obtained.

b. Replace capscrew.

Gas Input

— Determine the gas input as follows:

1. Natural Gas

a. Turn off all other gas appliances and pilots.

b. Measure time (in seconds) for gas meter test

dial to complete one revolution.

c. Divide 3600 by time noted and multiply result

by number of cu ft per revolution of test dial

(read off meter test dial).

________3600________ ^

seconds per revolution

cu ft per _ cu ft

revolution per hr