Start-up. adjustment and safety check, Sequence of operation – Carrier 58GS User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

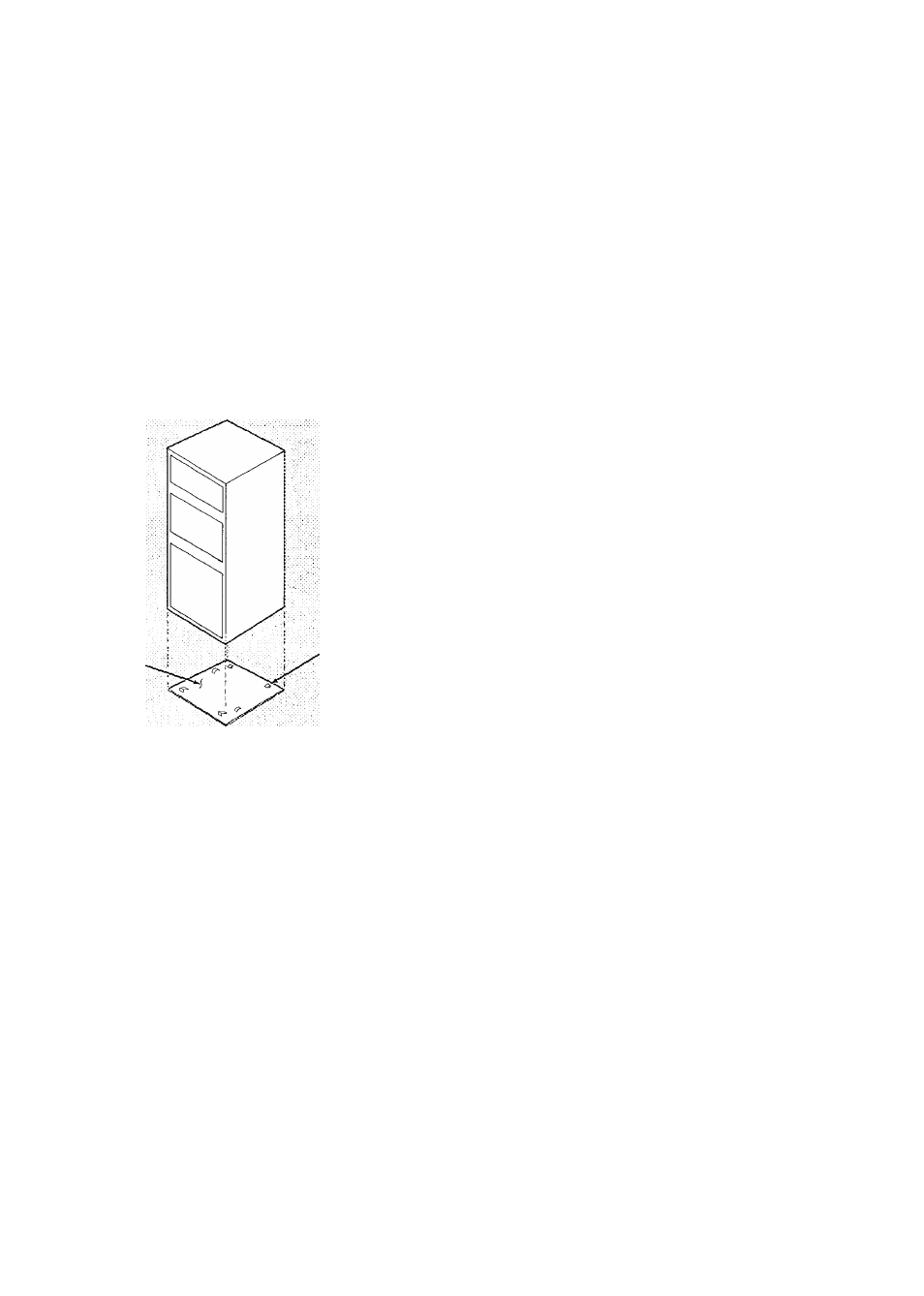

BOTTOM CLOSURE PANEL — When the side

inlet is used, the bottom opening must be properly

sealed by installing a bottom closure panel shipped

under the filter in each furnace. To install the

bottom closure panel, perform the following steps:

1

.

After filter has been installed for side return, re

move bottom closure panel from furnace.

With furnace either tilted or raised, install panel

in opening on bottom of furnace, making certain

that locating tabs rest securely against sides

of cabinet. See Fig. 9.

WARNING: Never operate unit without a iiiter

or with filler acce.ss door removed-

eorroM

aosu!^ PANEL

LOCATING TASS

Fig. 9 — Installing Bottom Closure Panel

START-UP. ADJUSTMENT AND

SAFETY CHECK

Sequence of Operation

HEATING — Sizes 050 thru 150 (BDP 646AW gas

valve)

TIME (sec)*

ACTION

0

35

“”45'’

11b

20

75

Thermostat calls for heat. The control circuit be

tween R and W is closed: power from transformer

simultaneously opens solenoid of pilot gas valve

(inside main gas valve) and energizes spark

igniter

PiTot^as ignites

TTlof coritacTslnbffnaTly closed) open.'Spark

igniter ceases to spark

Pilot contacts (normally open) close, energizing

heat motor in main gas valve and solid-state

timing circuit in printed circuit control centejr^______

Heat motor opens main gas valve; main Burners

ignite from pilot flame

SoHd^itife tirning'cnxuiUswitches iti contacts

and blower motor starts

Thermostat is satisfied. Circuit between R and W

is broken; automatic gas valve is de-energized,

closing solenoid valve Solid-state timing circuit

is de-energized

T^in gas "valvelmd pilot valve close, extinguishing

flame

Piiot safety contacts open.

PIloTcontacts cioseTready for new cycle Solid-

state timing circuit switches its contacts, stopping

blower motor

‘Times are approximate: variance ±20%

HEATING — Size 175 (Essex 242 gas valve)

TIME (sec)*

0

75

1

75

ACTION

Thermostat calls for heat, power from transformer

simultaneously opens solenoid of pilot gas valve

(inside main gas valve) and energizes spark

igniter Solid-state timing circuit is energized

Pilot gas ignites

Once pilot flame is proven electrically, igniter

ceases to spark, main gas valve opens and mam

burners ignite from pilot flame

Solid-state timing circuit switches its confacfs

and blower motor starts

Thermostat is satisfied Pilot and main gas valves

are de-energized Solid-state timing circuit is

de-energized

_

_

Pilot and main burners are extingmsh^_ ____________

Solid-state timing circuit switches its contacts,

stopping blower motor

‘Times are approximate, variance ±20%

LIMIT SWITCH — If the furnace overheats for

any reason, the limit switch will open, breaking the

circuit to automatic gas valve, so the gas valve

closes immediately. Without low-voltage current

applied to heat relay, its normally closed contacts

energize blower motor.