Adjustment of blower speed – Carrier 58GS User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

d. Multiply cu ft per hour times heating value of

gas (Btu/cu ft). Obtain heating value of gas

from local utility.

X heat value of gas

= gas input, Btuh

Example:

Time for one revolution of 2 eu ft dial = 72

seconds.

Heat value of gas = 1070 Btu/cu ft

3600

72

X 2 = 100 cu ft/hr

100 X 1070 = 107,000 Btuh

e. To adjust input rate, remove cap that con

ceals regulator adjustment. Turn adjusting

screw counterclockwise (out) to decrease

input. When adjusting, DO NOT change

manifold pressure more than 0.3 in. wg. Any

major adjustment should be made by chang

ing orifices.

2. High Altitude

Ratings are approved for altitudes to 2000 ft

for all gases. Ratings for altitudes over 2000 ft

are 4% less for each 1000 ft above sea level.

Adjust Main Burner Flame

— The main burner

flame should be clear blue, almost transparent, with

a well-defined inner cone. If there is too much pri

mary air, the flame will be well defined, but with a

tendency to float or lift off the burner ports.

1. Allow unit to operate 5 minutes.

2. When burners are equipped with primary air

adjustment, adjust each burner by closing air ad

justment device until slight yellow tip appears on

flame; then open, just enough to clear yellow

from flame.

Temperature Rise

— Determine the air tem

perature rise as follows:

1. Place duct thermometers in return and supply

ducts as near furnace as possible. Be sure

thermometers do not “see” heat element so that

radiant heat will not affeet thermometer read

ings. This is particularly important with straight-

run ducts.

2. When thermometers stabilize, subtract return air

temperature from supply air temperature to

determine air temperature rise.

3. Adjust air temperature rise by adjusting blower

speed. Increase blower speed to reduce tempera

ture rise. Decrease blower speed to increase

temperature rise.

Adjustment of Blower Speed

WARN!N

changing speed, tap.

To change motor speed, remove the electric lead

from left side of Molex speed selector (see Fig. 7)

and relocate it on the desired terminal on the plug-in

terminal block/ speed selector located on the blower.

The white lead remains in the “C” (common) ter

minal at all times. The black lead (on heat/cool

models) is used to select the proper speed for

cooling mode and the red lead is used to select the

speed for heating mode.

CAOTTON: "Whien adjasisn^ ihe blower speed,

make cefiain that the temperature rise across

the heat exchanger does not exceed that speci

fied on the rating plate.

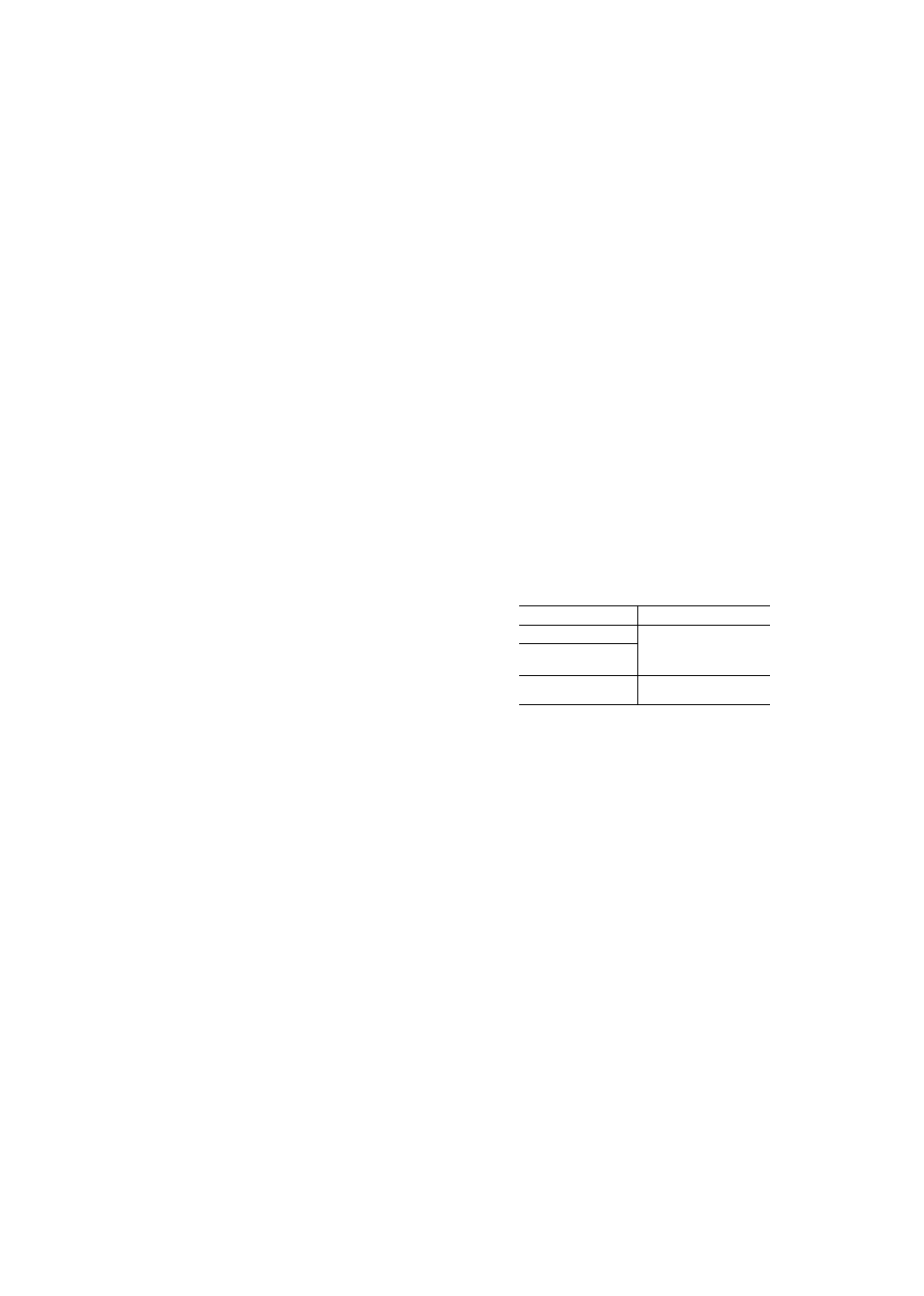

Table 3 — Speed Selector

SPEED

TAP NO

Common

C

Hi

...................... 1......................

Med-Hi

2

Med-Lo

3

Lo

4.......................

NOTE: Series 100 (heating only) and 150-200 have

3-speed motor.

Limit Control Safety Check

— This control

shuts off the gas and energizes the blower

motor if the furnaee becomes overheated.

The recommended method of checking the

limit control is to gradually block off the return

air after the furnace has been operating for a

period of at least 5 minutes. As soon as the

limit has proven safe, the return air opening

should be unblocked to permit normal air circu

lation. By using this method to check the limit

control, it can be established that the limit is

functioning properly and will “fail-safe” if there

is a motor failure.

10