A warning – Carrier 58TUA User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A WARNING

When this furnace is converted to Category III it must have its

own dedicated vent. DO NOT common vent with any other

appliance. Common venting with other appliances will result

in spillage of flue gas and failure of vent system which may

cause property damage, personal injury, or death.

A gastight heat dissipator, condensate drain tube and clamps,

condensate trap and mounting bracket, and draft safeguard modi

fication plate

are provided in the kit. No substitution for any of the components

may be made when installing furnace with a Category III vent

system.

A WARNING

Table 6 lists the required vent size for furnace sizes based on

high-fire input. Refer to the furnace rating plate and Table 6

to determine size of Special Gas Vent pipe. An incorrectly

sized vent may cause inadequate wind resistance, poor

operation, or vent failure. Vent failure may result in property

damage, or flue gas spillage, resulting in personal injury or

death.

Table 6—Vent Pipe Size*

HIGH-FIRE INPUT

(BTUH)NORMAL POSITION

PIPE DIAMETER

40,000—84,000

3 in.

85,000—140,000

4 in.

*Only Category III conversion kit specified on furnace and pipe size listed for

furnace input shall be used.

All joints in the vent system, between vent system and heat

dissipator, and between heat dissipator and furnace must be sealed

airtight with only the high temperature RTV specified by the

special gas vent pipe manufacturer. The accessory kit contains

provisions for vent condensate drainage. Drain and trap must be

installed pet kit instructions. Incorrect drain installations may

cause furnace component failure. Furnace installations in uncon

ditioned spaces where temperature may fall below 32°F REQUIRE

freeze protection (heat tape) on condensate trap.

HIGH TEMPERATURE PLASTIC, SPECIAL GAS VENT IN

STALLATION

Cutting

1. Hand cut piping with a sharp saw. Saw blade must have at

least 24 teeth pet in.

2. Cut pipe squarely. Use of a miter box when cutting pipe is

recommended.

NOTE:

DO NOT cut with power saw. Doing this may cause

immediate or eventual cracking or shattering of pipe. DO NOT cut

or alter fittings.

Adhesive Joining

Pipe and fittings are joined together using high temperature RTV

adhesive/sealants. Use ONLY adhesives listed by vent manufac

turer. Do not use any other adhesives or sealants. Do not use

solvent cements.

Do not drill holes in pipe or fittings. Do not use sheet metal or

other types of screws to join plastic piping or fittings. Do not use

rivets to join piping or fittings.

Before applying sealant, pipe ends must be smooth and clean.

1. Apply minimum 1/4-in. bead of adhesive/sealant entirely

around pipe end no more than 1/8-in. from end.

2. Push pipe and fitting together while twisting pipe into fitting.

3. Inspect joint for complete seal. Full curing of joints takes 24

hr.

A WARNING

Failure to ensure complete seal of all joints between furnace,

heat dissipator, vent pipes, and fittings will allow spillage of

flue gas, which may result in personal injury or death.

Inspect each joint after the adhesive/sealant has cured to ensure

that all joints are sealed. Reapply adhesive/sealant to any joints

that are suspected of flue gas leakage.

Vent Installation

Minimum vent length is 5 ft of straight pipe, one 90° long-radius

(sweep) elbow or equivalent, condensate drain assembly, and

termination (coupling and bird screen).

Maximum vent length is 40 ft of straight pipe, four 90° long-radius

(sweep) elbows, condensate drain assembly, and termination

(coupling and bird screen).

Length and number of elbows may be adjusted according to

equivalent ft of pipe for fittings shown in Table 7.

Example: If adding an additional 90° long-radius (sweep)

elbow, in a 3-in. diameter vent system, maximum vent length

must be reduced to 35 ft.

A coupling and bird screen are the recommended vent termination

for both horizontal and vertical vents. If a tee and 2 bird screens are

required for vertical vents, the allowable vent length must be

adjusted according to Table 7. No elbows shall be used as

terminations.

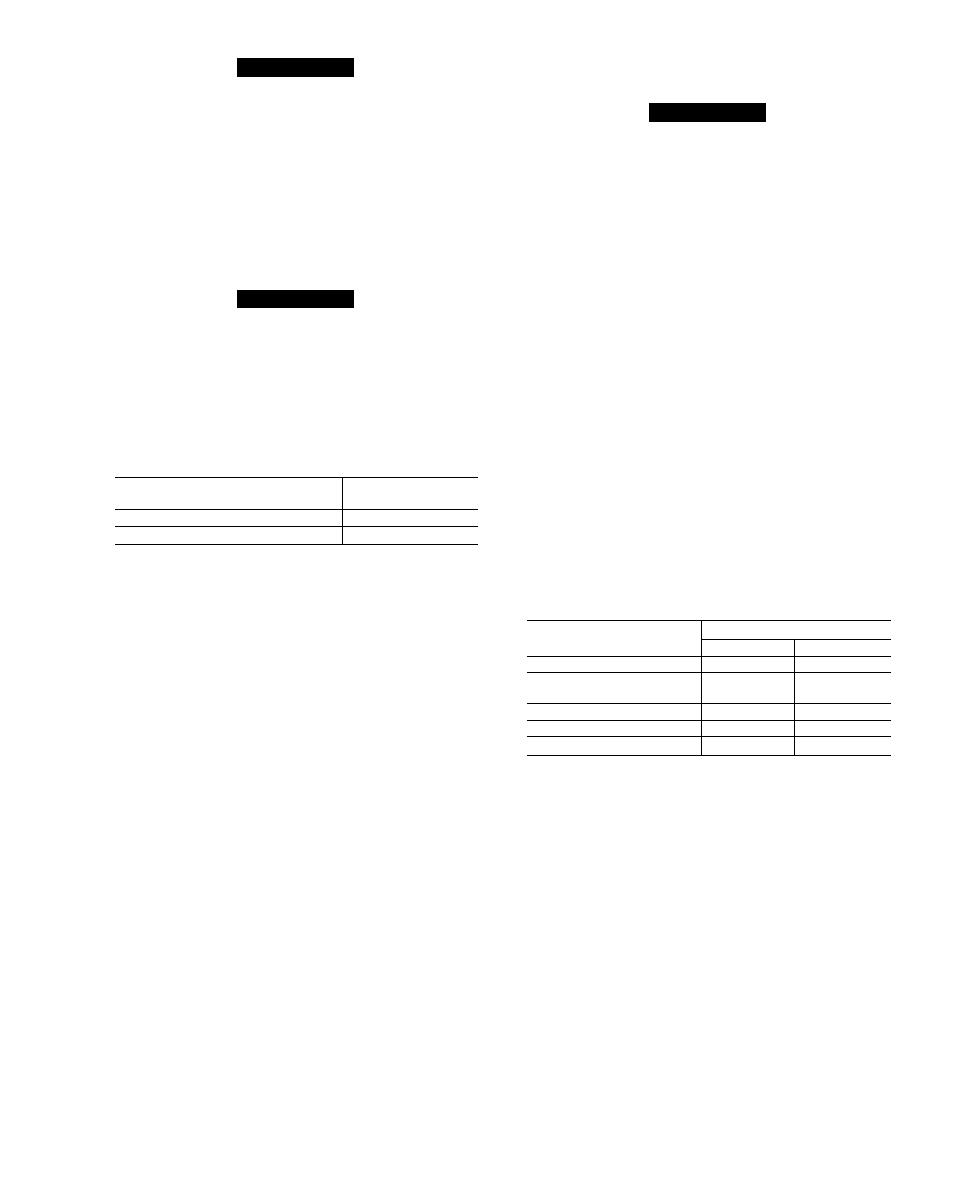

Table 7—Equivalent Pressure Drop in Length of

Straight Pipe for Fittings

FITTING

EQUIVALENT FT OF PIPE

3-In. Diameter

4-In. Diameter

90° Elbow

10

N/A

90° Sweep Elbow (Long-

Radius)

5

6

45° Elbow

5

5-1/2

Tee Used as an Elbow

10

10

Tee Used as a Termination

5

5

N/A—Not applicable

All horizontal mns of piping must slope backward towards drain

tee 1/4 in. per ft. The horizontal run between the drain tee and the

furnace must also slope towards the drain tee. Vent system must be

supported at least every 5 ft and at every elbow on horizontal mns.

Vertical mns must be supported at least every 10 ft by supports

listed by vent pipe manufacturer. Frame opening in floor using

lumber which is dimensionally consistent with stmctural members.

Framing must be level and must provide required air space

clearance to pipe.

Vertical Vent Termination

Where vent passes through roof, a listed flashing and storm collar

must be used to maintain required clearances and to keep weather

out. Framed opening must be large enough to maintain required air

clearance taking into account slope of roof. Install flashing and

storm collar as directed by vent manufacturer. Vertical termination

must be at least 2 ft horizontally from roof surface, at least 8 ft

away from any vertical wall, and must extend above roof as

required in kit instmctions. Vents extending 2-1/2 ft or more above

roof must be securely guyed or braced according to vent manu

facturer’s Installation Instructions. Terminate with a coupling and

a bird screen.