A caution – Carrier 58TUA User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

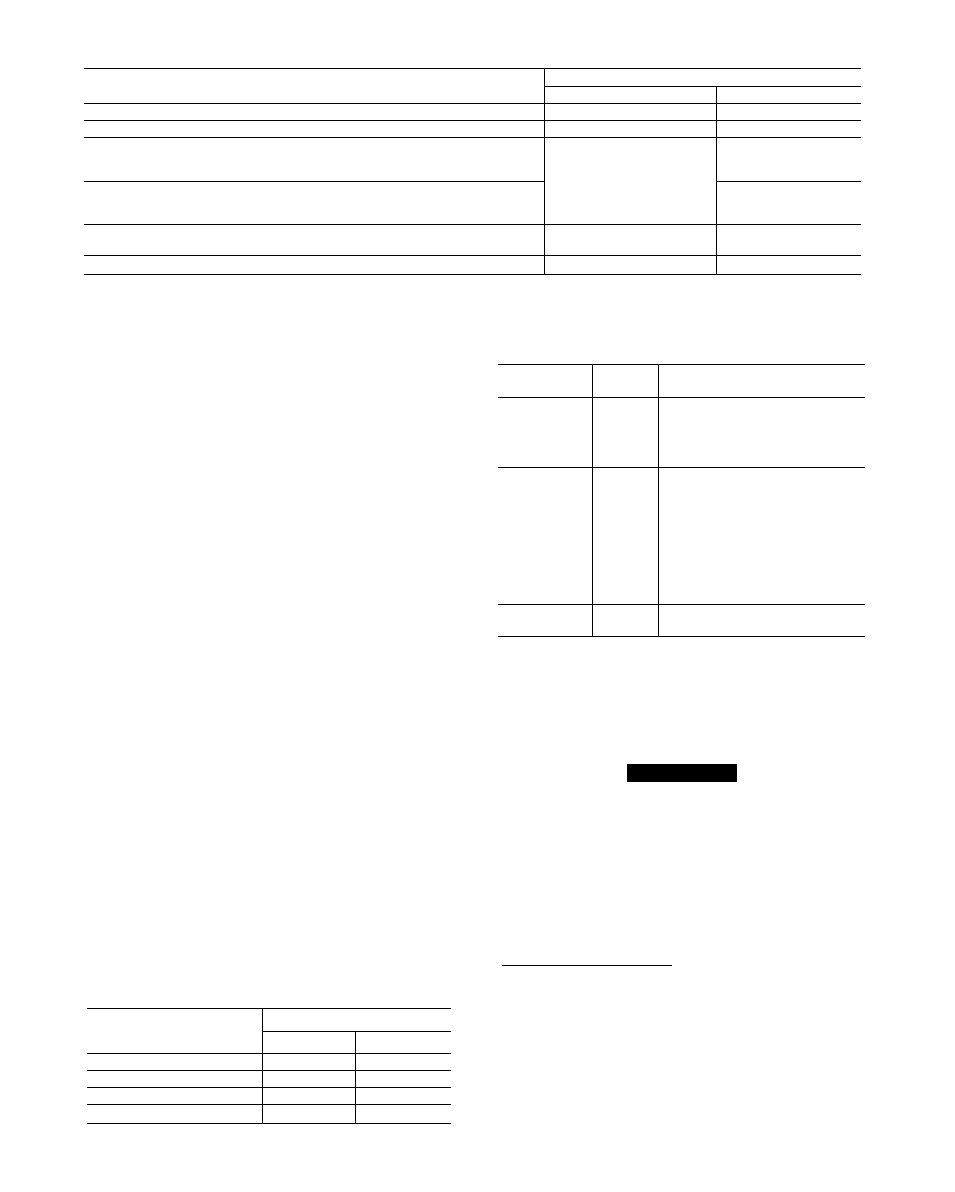

Table 8—Horizontal Vent Termination Clearances

LOCATION

CLEARANCE (FT)

U.S.A.

Canada

Above anticipated snow depth

1

1t

From mechanical fresh air intake

1

6

For furnaces with an input capacity less than 100,000 Btuh

from any nonmechanical air supply (such as a door or win

dow) or combustion-air opening

4 below

4 horizontally

1 above

i

For furnaces with an input capacity greater than 100,000 Btuh

from any nonmechanical air supply (such as a door or win

dow) or combustion-air opening

3

From service regulator vent, electric and gas meters and re

lief equipment

4*

6t

Above grade when adjacent to public walkway

7

7

‘Horizontal distance.

t36 in. to electric meter.

its in. above roof surface in Canada.

Horizontal Vent Termination

NOTE:

Do not locate the vent termination close to shrubbery.

Flue gas may stunt growth or kill shrubs. Combustion products

may affect unprotected building material surfaces. Sealing or

shielding of exposed surfaces with a corrosion resistant material

may be required in these cases.

NOTE:

In U.S.A., vent must terminate 3 ft above any mechanical

, fresh air intake within 10 ft.

After vent system is installed, inspect all joints and supports. If all

joints are secure, fully seated, and well supported by straps,

furnace may be started, adjusted per furnace Installation Instruc

tions, and placed into operation. See vent pipe manufacture’s

Installation Instructions: cure time may be required before oper

ating furnace.

Step

8—START-UP,

CHECK

ADJUSTMENT, AND SAFETY

GENERAL

The furnace must have a 115-v power supply properly connected

and grounded. Correct polarity must be maintained to enable

operation.

The gas service pressure must not exceed 0.5 PSIG (14-in. wc), but

be no less than 0.16 PSIG (4.5-in. wc).

Thermostat wire connections at R and WAVl are the minimum

required for gas heating operation. W2 must be connected for

2-stage heating thermostats. COM, Y/Y2, and G are required for

cooling, heat pumps, and some clock thermostats. These must be

made at the 24-v terminal block on the control. (See Fig. 10.)

This furnace can be installed with either a single-stage heating or

a 2-stage heating thermostat. For single-stage thermostats, connect

thermostat R to W/Wl at the furnace control terminal block. (See

Fig. 8.) For single-stage thermostats, the control will determine,

based on length of previous heating cycles, when to operate in low

and high gas heat for optimum comfort. Setup switch-2 (SW-2)

must be in the factory-shipped OFF position. See Fig. 11 and

Tables 9 and 10 for setup switch information.

Table 9—Blower Off Delay Setup Switch Position

DESIRED HEATING

MODE BLOWER OFF

DELAY (SEC)

SETUP SWITCH

SW-3

SW-4

90

OFF

OFF

135

ON

OFF

180

OFF

ON

225

ON

ON

Table 10—Setup Switch (SW) Description

SETUP

SWITCH NO.

NORMAL

POSITION

DESCRIPTION

OF USE

SW-1

High Gas Heat

OFF

Turn switch ON to obtain high gas

heat operation on any call for heat

regardless of whether *R-W/W1, or

R-W/W1, -W2 is closed. SW-1 over

rides SW-2.

SW-2

Low Gas Heat

OFF

Turn switch OFF for installations

with single-stage thermostats; con

trol selects low gas heat or high gas

heat operation based on previous

cycles. Turn switch ON for installa

tions with 2-stage thermostats to

permit only low gas heat operation

in response to closing *R-W/W1.

High gas heat is supplied only when

R to W/W1 and W2 is closed.

SW-3, and

SW4

ON, OFF

Switches control gas heating mode

blower off delay. See Table 9.

K a 2-stage heating thermostat is to be used, move SW2 to the ON

position at the end of the furnace installation. This will override the

built-in control process for selecting high and low fire and allow

the 2-stage thermostat to select heating modes. The W2 from the

thermostat must be connected to W2 on the control terminal block.

(See Fig. 9.)

A CAUTION

This furnace is equipped with a manual reset limit switch in

the gas control area. The switch will open and shut off power

to the gas valve if a flame rollout or overheating condition

occurs in the gas control area. DO NOT bypass the switch.

Correct inadequate combustion-air supply, component fail

ure, or restricted flue gas passageway and reset the switch.

Before operating the furnace, check each manual reset switch for

continuity. If necessary, press and release the button to reset the

switch.

SEQUENCE OF OPERATION

Using the schematic diagram in Fig. 12, follow the sequence of

operation through the different modes. Read and follow the

diagram

very carefully.

NOTE:

If a power interruption occurs during a call for heat

(W/Wl or WAVl and W2) and if the thermostat is still calling for

gas heating, the control will start a 90-sec blower-only ON period

2 sec after power is restored. The LED red light will flash code 12

during the 90-sec period, after which the LED will be ON

continuous, as long as no faults are detected. After the 90-sec

10