A warning – Carrier 58TUA User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

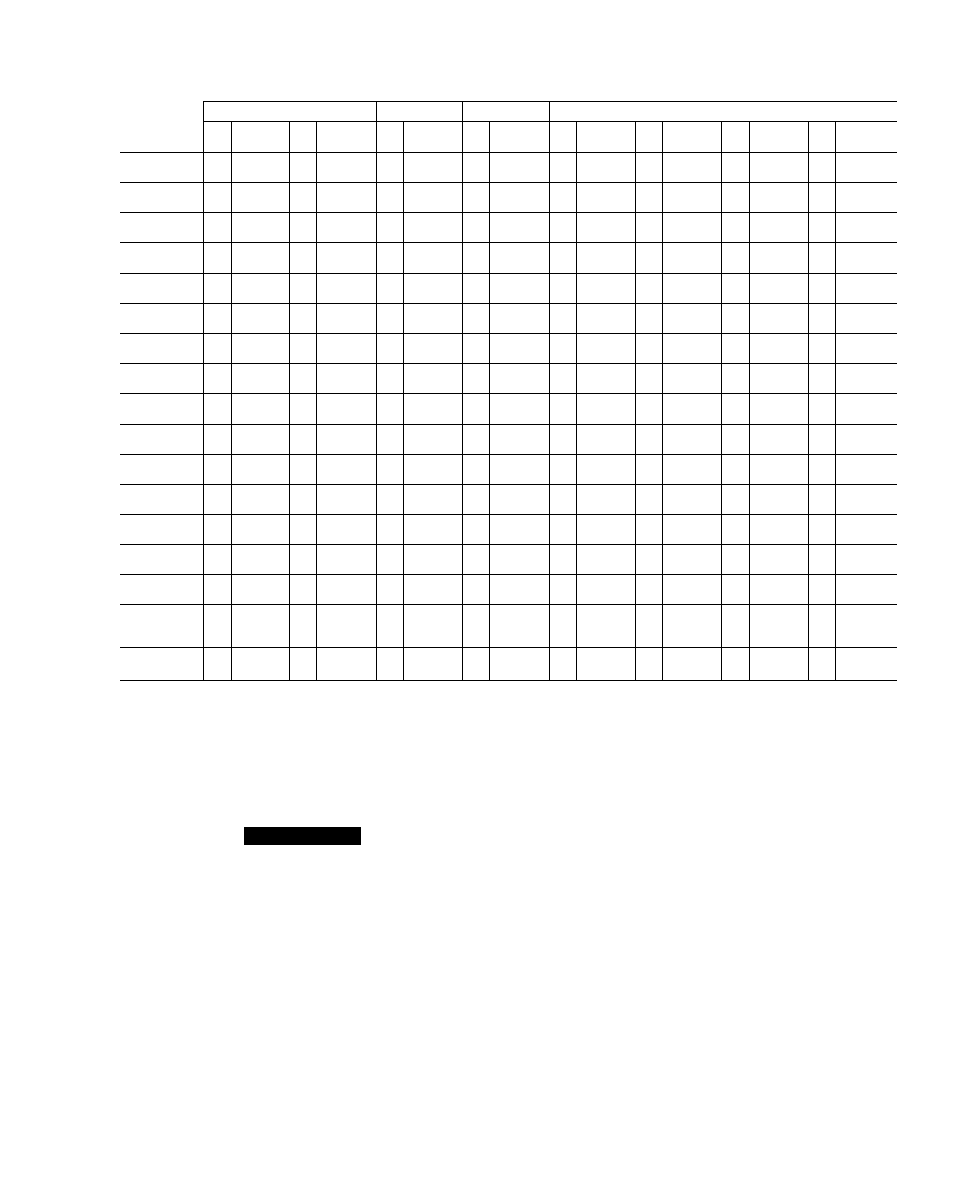

Table 11—Model 58TUA Orifice Size and Manifold Pressure for Correct Input Rate (Tabulated Data Based on

Altitude Up to 2000 ft and 20,000 Btuh High Heat/13,000 Btuh Low Heat Per Burner)

GAS HEAT

VALUE

(BTU/CU FT)

0.58 0.60

0.62

0.64

0.66 0.68 0.70 , 0.72

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

860

43

3.7/1.6

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

42

3.4/1.5

41

42

3.2/1.4

3.6/1.5

41

42

3.3/1.4

3.7/1.5

41

42

3.4/1.4

3.8/1.6

875

43

3.6/1.5

43

3.7/1.6

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

42

3.4/1.4

41

42

3.2/1.3

3.5/1.5

41

42

3.3/1.4

3.6/1.5

890

43

3.5/1.5

43

3.6/1.5

43

3.7/1.6

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

42

3.4/1.4

41

42

3.2/1.3

3.5/1.5

905

43

44

3.3/1.3

3.7/1.5

43

3.5/1.4

43

3.6/1.5

43

3.7/1.5

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

42

3.4/1.4

920

43

44

3.2/1.3

3.7/1.5

43

44

3.3/1.4

3.8/1.6

43

3.5/1.4

43

3.6/1.5

43

3.7/1.5

43

3.8/1.5

42

3.2/1.3

42

3.3/1.3

935

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

43

44

3.3/1.4

3.8/1.6

43

3.5/1.5

43

3.6/1.5

43

3.7/1.5

43

3.8/1.6

42

3.2/1.3

950

44

3.5/1.5

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

43

44

3.3/1.4

3.8/1.6

43

3.4/1.5

43

3.6/1.5

43

3.7/1.5

43

3.8/1.6

965

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

43

44

3.3/1.4

3.8/1.6

43

3.4/1.5

43

3.5/1.5

43

3.6/1.5

980

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

43

44

3.3/1.4

3.8/1.6

43

3.4/1.5

43

3.5/1.5

995

44

45

3.2/1.3

3.8/1.6

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

43

44

3.3/1.4

3.8/1.6

43

3.4/1.4

1010

45

3.7/1.6

44

45

3.2/1.3

3.8/1.6

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

43

44

3.3/1.4

3.8/1.6

1025

45

46

3.6/1.5

3.8/1.6

45

3.7/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

43

44

3.2/1.4

3.7/1.6

1040

45

46

3.5/1.5

3.7/1.6

45

46

3.6/1.5

3.8/1.6

45

3.7/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

1055

45

46

3.4/1.4

3.6/1.5

45

46

3.5/1.5

3.7/1.6

45

46

3.6/1.5

3.8/1.6

45

3.8/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

1070

45

46

3.3/1.4

3.5/1.5

45

46

3.4/1.4

3.6/1.5

45

46

3.5/1.5

3.7/1.6

45

46

3.7/1.5

3.8/1.6

45

3.8/1.6

44

3.2/1.4

44

3.3/1.4

44

3.4/1.4

1085

45

46

47

3.2/1.4

3.4/1.4

3.8/1.6

45

46

3.3/1.4

3.5/1.5

45

46

3.4/1.5

3.6/1.5

45

46

3.6/1.5

3.7/1.6

45

3.7/1.5

45

3.8/1.6

44

3.2/1.4

44

3.3/1.4

1100

46

47

3.3/1.4

3.7/1.6

45

46

3.2/1.4

3.4/1.4

45

46

3.4/1.4

3.5/1.5

45

46

3.5/1.5

3.6/1.5

45

46

3.6/1.5

3.8/1.6

45

3.7/1.6

45

3.8/1.6

44

3.2/1.4

£. The gas valve and humidifier terminal HUM are not

energized for safety reasons.

NOTE:

The EAC terminals are energized when the blower is

energized.

2. Purge gas lines—After all connections have been made, purge

the lines and check for leaks.

A WARNING

Never purge a line into a combustion chamber. Never use

matches, candles, flame or other sources of ignition for the

purpose of checking leakage. Use a soap-and-water solution

to check for leakage. A failure to follow this warning can

cause a fire, explosion, personal injury, or death.

3. To operate furnace, follow procedures on operating instruc

tions label attached to furnace.

4. With furnace operating, set thermostat below room tempera

ture and observe that furnace goes off. Set thermostat above

room temperature and observe that furnace restarts.

ADJUSTMENTS

1. Set gas input rate.

The gas input rate must be set for both high-fire and low-fire.

Each adjustment is independently made at the gas control

regulators.

Therfe are 2 methods of adjusting the gas input rate. The

preferred method is by using Table 11 and item a. The second

method is by clocking the gas meter as outlined in item b.

The Procedure in item b. MUST be used for altitudes above

2000 ft.

The gas valve regulator has been nominally set at 1.5-in. wc

for low fire and 3.5-in. wc for high fire for natural gas.

a. Check gas input rate using Table 11.

(1.) Obtain average yearly heat value for local gas supply.

(2.) Obtain average yearly specific gravity for local gas

supply;

(3.) Verify furnace model. Table 11 can only be used for

Model 58TUA Furnaces.

(4.) Check and verify orifice size in furnace. NEVER

ASSUME THE ORIFICE SIZE. ALWAYS CHECK

AND VERIFY.

(5.) Find natural gas heat value and specific gravity in

Table 11.

(6.) Follow heat value and specific gravity lines to point of

intersection. Find orifice size and manifold pressure

settings for proper operation at given natural gas

conditions on low and high fire.

15