Caafsoi be, Compressor removal — 50qt112, 115, 118, Coupi.{(«5aocif – Carrier 50QT User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

AccuRater™

Device

(Dual-Piston

Type)

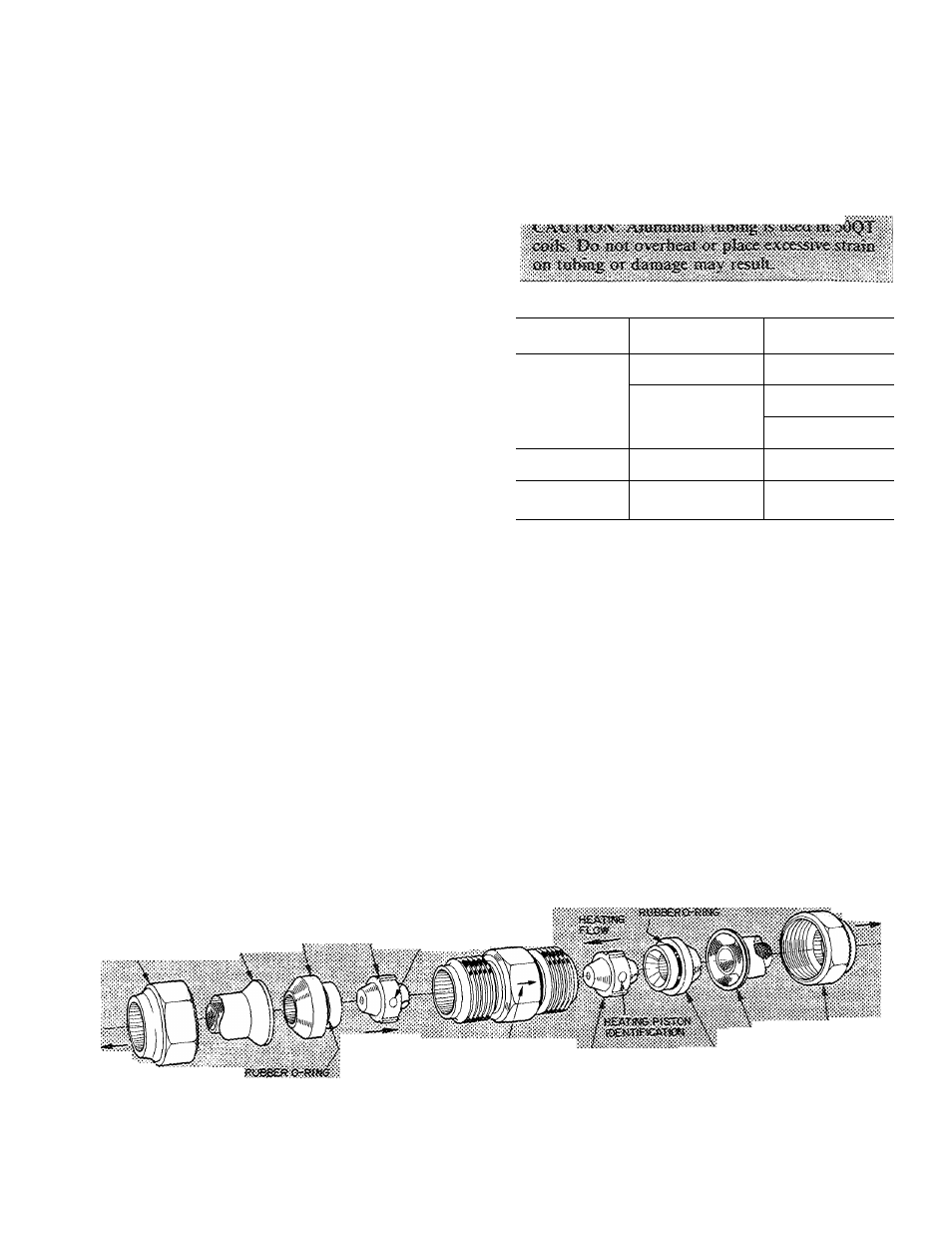

Servicing — See Fig. 15 for dual-piston AccuRater

components. The pistons have a refrigerant meter

ing orifice through them. The retainers form a stop

for the pistons in the refrigerant bypass mode, and

a sealing surface for liquid line flare connection.

To clean or replace piston;

1. Shut off power to unit.

2.

Protect area around unit to prevent damage to

interior, furnishings, etc.

3. Remove refrigerant from unit.

4.

Remove liquid line flare connections from

AccuRater. See Fig. 3 for AccuRater location.

5. Note position of arrow on AccuRater body in

relation to unit.

6.

Pull retainer out of body. Be careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use locking pliers to

remove retainer. Replace scratched or damaged

retainer.

7. Slide piston out by in.serting a small soft wire

through

metering

hole

(18-gage

thermostat

wire). Check that metering hole, sealing surface

around

piston

cones and

fluted

portion of

piston are not damaged.

8. See chart on indoor blower scroll for illustration

of proper arrangement and sizes of pistons.

9. Clean piston refrigerant metering orifice.

10.

Replace retainer O-ring before reassembling

AccuRater.

Carrier

O-ring

Part

No.

is

99CC501052.

LIQUID LINE STRAINERS (protect AccuRater),

are made of wire mesh and located in the liquid line

on each side of the AccuRater. The strainers are

pressed into the line. Remove strainer by threading

a #10 sheet metal screw into strainer and pulling

the screw with pliers.

Compressor Removal — (Refer to Fig. 2.)

caafsoi

be

xaoVfiiS fmm aa btsislied cfesssis* Rmove

fnbi» sleeve, feratg. io &eTvice ijttcfe

or deales' sJiojr T^efore retaoviag coiap-ressor.

See Table 3 for compressor information. Follow

safety codes and wear safety glasses and work

gloves. Have quenching cloth available.

Table 3 — Compressor Data

UNIT 50QT

CONIPRESSOR

OIL RECHARGE

(oz)

112

Copeland

RE-Z30150-PFV

20

115

Tecumseh

AB5515H

32

118

Copeland

CRB1-0175 PFV

51

124

Copeland

CRD-10200-PFV

51

130

Copeland

CRF1-0250-PFV

51

Compressor Removal — 50QT112, 115, 118

1. Shut off power to unit. Remove chassis indoor

cover, Fig. 1.

2. Remove chassis to truck or shop.

3.

Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service

Techniques

Manual,

Chapter

I,

Refrigerants.

4.

Remove core from suction and discharge line

Schrader valves.

5. Remove compressor guard.

#

mr

CQCSL»i&

coociweEssTOii

iOQiTirtCATiOM

'50

(«BOOR

TO

COOytiiS STA»P££f

coupi.{(«5aocif ,

STRiawes

i«>T£.

are too&iec « s i d e c i P A c c v R i a w

ssi cosi>t>0oeRt& ¡s ««(cai-fijr

correct

Fig. 15 — AccuRater Device (Dual-Piston) Components