Iajiiage or re^val eati tessli, Aot iisre waiec, steam – Carrier 50QT User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

w

recharge. If necessary, refer to Carrier Standard

Service

Techniques

Manual,

Chapter

1,

Refrig

erants, page 1-21, for oil recharging procedure. Use

Carrier PP33-1, Texaco WF-32 or Suniso 3GS oil.

FAN MOTOR BEARINGS — Oiling holes are pro

vided at each end of condenser fan motor. Remove

fan motor and lubricate motor with 32 drops (16

drops per hole) of SAE 10 nondetergent oil at

intervals described below:

a.

Annually, when environment is very dirty,

ambient temperature is higher than 105 F and

average unit operating time exceeds 15 hours

a day.

b.

Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F and

unit operating time averages 8 to 15 hours a day.

c.

Every 5 years when environment is clean,

ambient temperature is less than 105 F and unit

operating time averages less than 8 hours a day.

INDOOR MOTOR — To oil indoor motor, remove

dust caps or plugs from oil holes located at each end

of the motor. Use a teaspoon, 5 cc (5 ml), 3/16 oz or

16 to 25 drops of a good grade of SAE 20 nondeter

gent motor oil in each oil hole. Allow time for total

quantity of oil to be absorbed into each bearing.

After oiling motor, be sure to wipe off excess oil

from housing and replace cap or plugs on oil port.

Outdoor Coil Cleaning — To be done at the

beginning of each cooling season or more often if

required.

aot iiSre

waiec, steam>

or voiatUe or coiro^xve

oji tass

m

"

1. Shut off power to unit.

2.

Remove chassis from sleeve by removing 6 bolts

and sliding chassis out. Transport chassis to an

appropriate cleaning location.

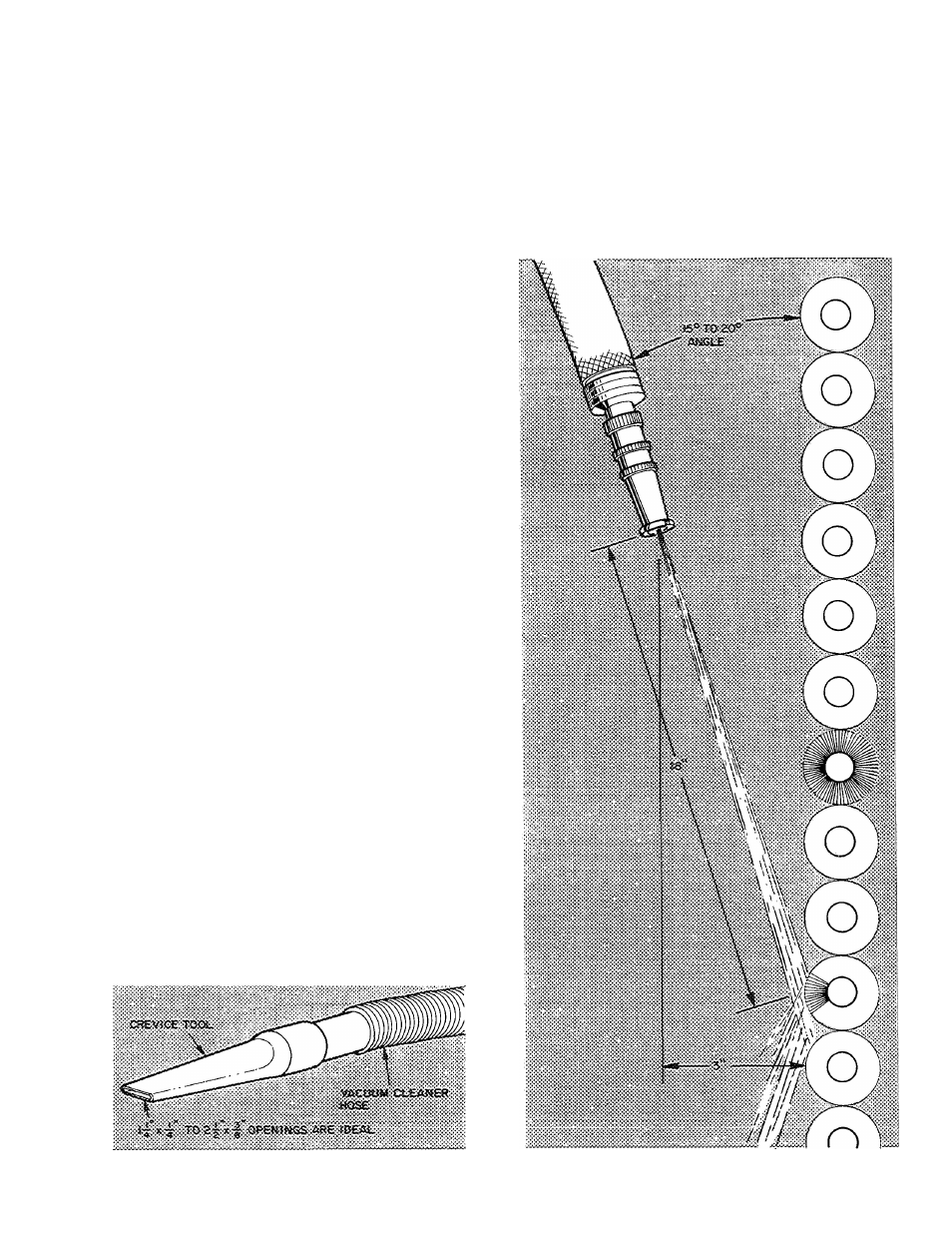

3. Clean coil using vacuum cleaner and its crevice

tool (see Fig. 16). Work crevice tool perpendicu

larly to coil tubes, making sure tool only touches

dirt on fins. To prevent fin removal, do not

“scrub” fins with tool or move tool parallel to

coil tube configuration.

4. If oil deposits are present, spray coil with liquid

household

detergent.

Wait

10

minutes,

then

proceed to step 5.

5. Using garden hose, spray coil perpendicularly to

coil tubes with a constant stream of water at

moderate pressure (see Fig. 17). Keep nozzle at a

15 to 20 degree angle, about 3 in. from coil face

and 18 in. from tube. Spray so debris is washed

out and away from coil making sure water does

not contact components on side of chassis.

Fig. 16 — Crevice Cleaning Tool

Fig. 17 — Positioning Hose to Spray Coil

II