Refrigerant charging, Catltiof^; to pfeveat persotial fejury. 'wear, Safeij; giasoe» ao<3 giovfes ha»d3t»g – Carrier 50QT User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

When an internal overload is suspected of being

open, check by using an ohmmeter or continuity

tester.

If

necessary,

refer

to

Carrier

Standard

Service Techniques Manual, Chapter 2, Electrical,

for complete instructions.

Defrost Control, consisting of a defrost timer,

defrost

thermostat

and

defrost

relay,

interrupts

normal system heating operation to remove frost

and ice formation on outdoor coil. Frost impairs

unit

performance.

Defrost

control

simultaneously

stops outdoor fan, energizes reversing valve sole

noid to switch system into cooling cycle (outdoor

unit

as

condenser,

indoor

unit

as

evaporator),

and

activates

electric

heater.

Unit

can

defrost

every 90 minutes, but will do so only if outdoor

temperatures are in the frosting temperature zone.

For heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Coil temperature must be cold enough to cause

defrost thermostat contacts to close.

Contacts close at 28 ±3 F (50QT112 - 118) and

35 ± 3 F (50QT124, 130). Every 90 minutes of

elapsed running time, the defrost timer contacts

close for 10 seconds. If the defrost thermostat

contacts are closed, the unit defrosts. The defrost

timer

limits

defrosting

period

to

10

minutes.

Normally the frost is removed and the defrost ther

mostat contacts will open to terminate defrosting

before 10 minutes have elapsed. Defrost thermostat

contacts open at 65 ±5F (50QT112 - 118) and

75

±5F

(50QT124,130).

When

defrosting

is

terminated, the outdoor fan motor is energized

and reversing valve solenoid is de-energized, re

turning unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 4 are

refrigerant flow diagrams for heating and cooling

cycles.

Refrigerant Charging

CAtlTiOf^; To pfeveat persotial fejury. 'wear

safeij; giasoe» ao<3 giovfes

ha»d3t»g

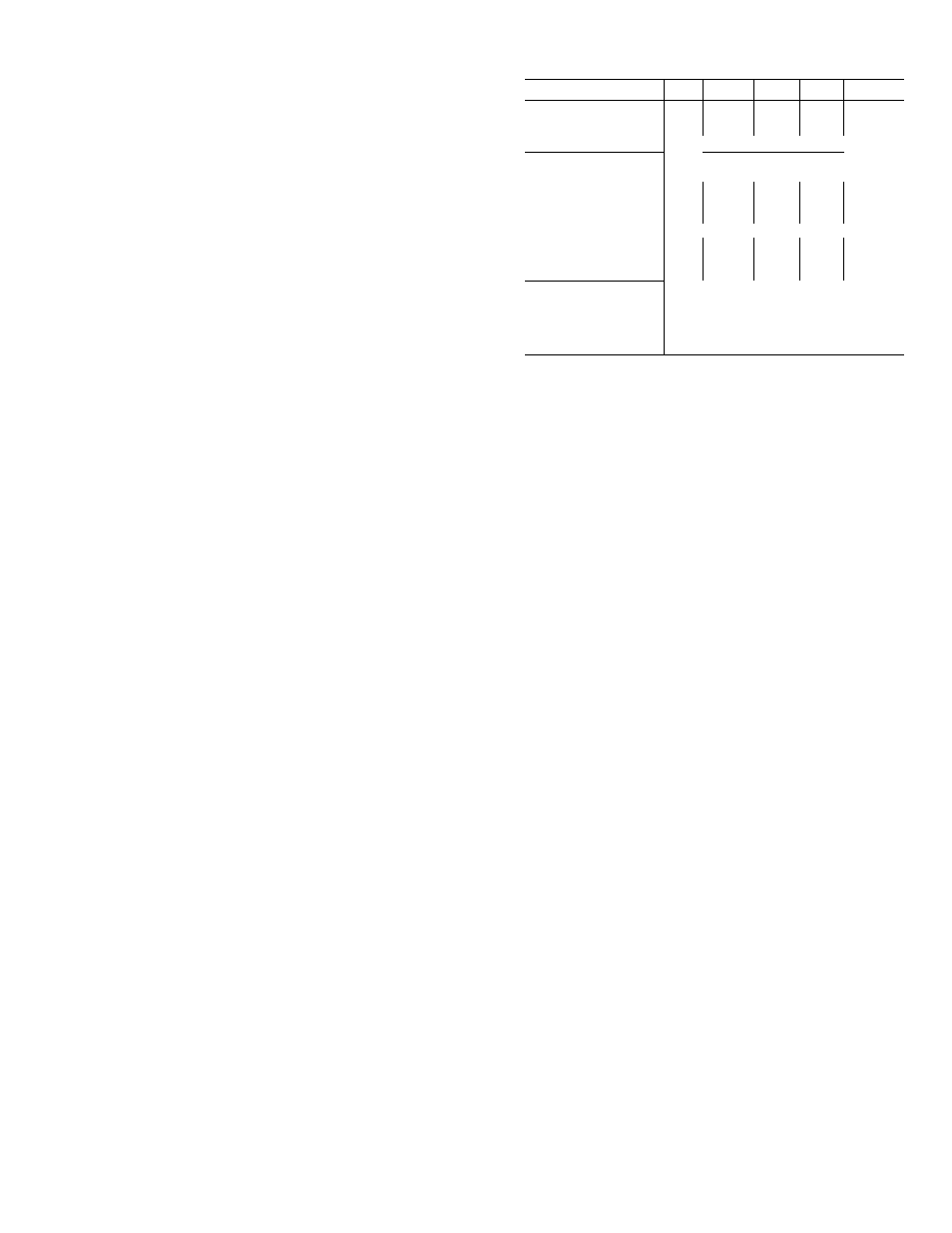

Table 2 — Service Data

Do not overcharge system. An overcharge can

cause compressor flooding.

Unit refrigerant system is factory charged. When

recharging is necessary, weigh in total charge indi

cated in Table 2. (Charge must be weighed in during

heating season.) Remove any refrigerant remaining

in system before recharging. If system has lost com

plete charge, triple-evacuate system to 5000 microns

(29.7 in. vacuum) before recharging. Service port

connections are provided on unit suction and dis

charge lines for evacuation and charging. (See Fig. 4

for service port location.) Dial-a-charge charging

cylinder is an accurate device used to recharge

systems by weight. These cylinders are available at

refrigeration supply firms.

UI\IIT50QT

112

115

118

124

130

MODEL

300

300

300

300

300

R-22 CHARGE* (lb)

2 7

2 7

3 2

4 5

47

Refrig Control

AccuRater™ Bypass Type

INDOOR FAN

Centrifugal Blower,

Direct Drive, 2-Speed

Rotationt

CW

CW

CW

CCW

CCW

Rpm

1580

1550

1570

1675

1675

Diameter (in )

6

6

6

7

7

Width (in.)

8

430/

550/

575/

885/

1025/

Range (cfm)

375

475

480

800

960

Motor Hp

'A

'A

Vs.

'/4

V4

OUTDOOR FAN

Propeller, Direct Drive, Single Speed

Cfm

1700

1700

1700

2000

2000

Rpm

1125

Diameter (in )

15

Motor Hp

Vs

ccw

cw

Counterclockwise

Clockwise

‘Factory

refrigerant

charge

fLooking at fan motor shaft

To check and/or adjust charge during cooling

season, use Cooling Cycle Charging Charts (Fig. 5,

7, 9, II, 13) and follow Charging Chart Method

below. The charging chart may also be used as an

alternate method of recharging system.

To check

system operation

during heating cycle,

use Heating Cycle Operation Check Chart (Fig. 6, 8,

10, 12, 14). These charts indicate whether a correct

relationship exists between system operating pres

sures and air temperatures entering unit. If pressure

and temperature lines do not intersect on chart,

the system refrigerant charge may not be correct

or other system abnormalities may exist. Do not

use Operating Check Charts to adjust refrigerant

charge. Weigh charge into system.

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

unit suction service port. (See Fig. 4 for correct

service port location.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature. Use service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor fan coil.

5. Refer to Charging Chart. Locate on curves where

outdoor air dry-bulb and indoor air wet-bulb

temperature lines intersect.

6.

From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure,

add

refrigerant

to

system

until

chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.