Step 6 — make electrical connections, Step 7 — make outdoor air inlet adjustments – Carrier 50DP016 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

(| )FPT

DRAIN CONNECTION^ U

(HALF COUPLING)

BASE RAIL-

u

TO TRAP -!>

Fig. 9 — Condensate Drain Piping Details

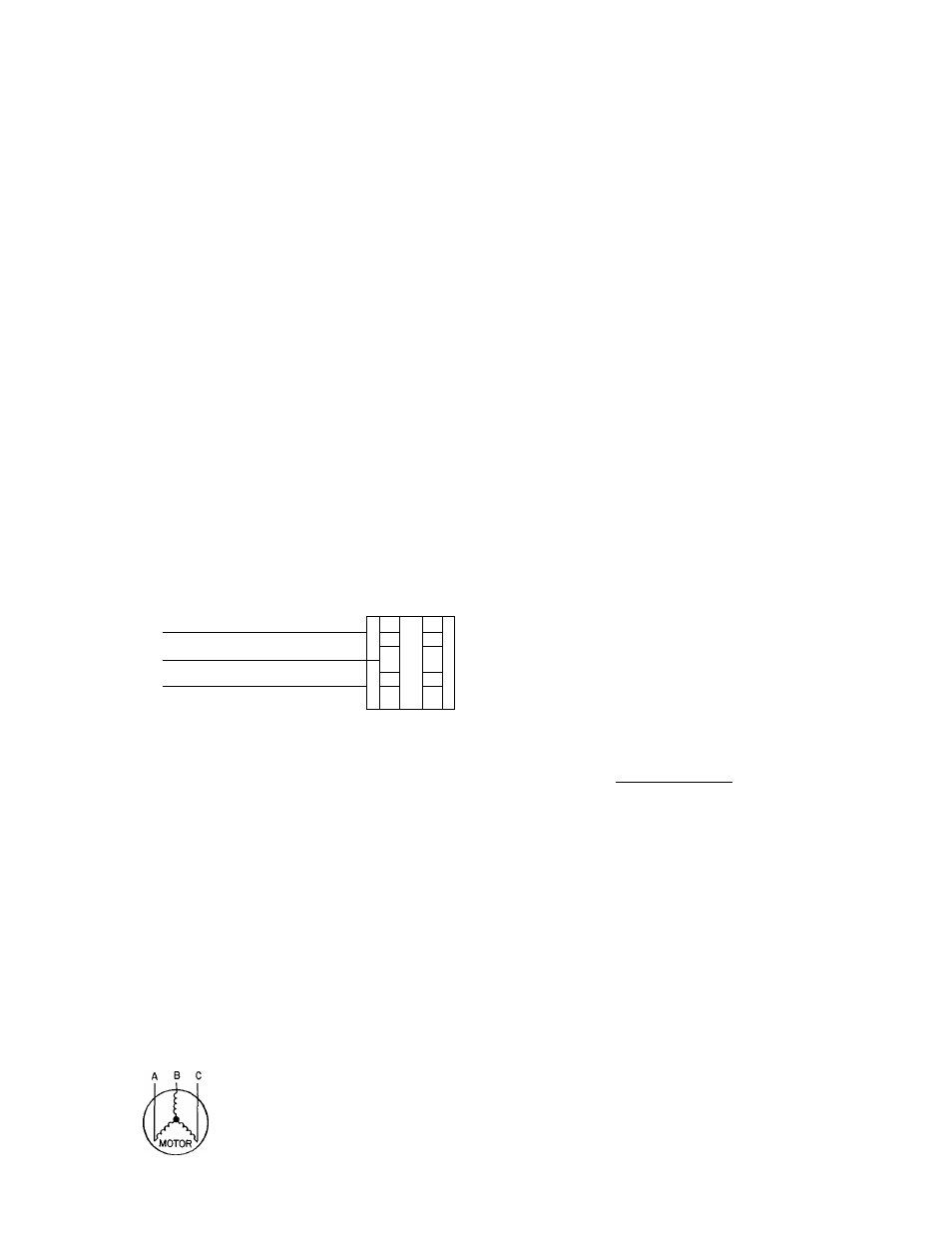

Step 6 — Make Electrical Connections

FIELD POWER SUPPLY ^ Unit is factory wired for

voltage shown on nameplate. Units are provided with

terminal bloek.

When installing units, provide a diseonnect per NEC

of adequate size (Table 2).

All field wiring must eomply with National Eleetrieal

Code and loeal requirements.

Route power lines through control box end panel — or

unit basepan — (Fig. 4) to terminal connections as shown

on unit wiring diagram and Fig. 10.

TBI

UjO

2

O IE

1 FIELD

1 1

•¿\

! POWER

\Z

1 SUPPLY

1

lá

¿6

OT Q.

r-\ •

_____I

EQUIP GND

Fig. 10 — Field Power Wiring Connections

Operating voltage to eompressor must be within

voltage range indieated on unit nameplate. On 3-phase

units, voltages between phases must be balanced within

2% and the eurrent must be balanced within 10%.

Use the following formula to determine the % voltage

unbalanee.

% Voltage Unbalanee

average voltage

Example; Supply voltage is 460-3-60.

AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage

452 + 464 + 455

1371

457

Determine maximum deviation from average voltage;

(AB) 457 - 452 = 5 volts

(BC) 464 - 457 = 7 volts

(AC) 457 ~ 455 = 2 volts

Maximum deviation is 7 volts.

Determine % voltage unbalanee;

7

% Voltage Unbalance = 100

~

1-53%

This amount of phase unbalance is satisfaetory as it is

below the maximum allowable

2%.

IMPORTANT; If the supply voltage phase un

balance is more than 2%, contaet your loeal electric

utility company immediately.

Unit failure as a result of operation on improper line

voltage or excessive phase imbalance constitutes abuse

and may eause damage to eleetrieal eomponents. Sueh

operation would invalidate any applieable Carrier

warranty.

FIELD CONTROL WIRING — Install a Carrier-

approved accessory thermostat assembly aecording to

installation instruetions ineluded with aecessory. Loeate

thermostat assembly on a solid wall in the eonditioned

space to sense average temperature.

Route thermostat eable or equivalent single leads of

no. 18 AWG colored wire from subbase terminals

through eonduit in unit to low-voltage connections as

shown on unit label wiring diagram and in Fig. 11.

NOTE; For wire runs up to 50 ft, use no. 18 AWG insu

lated wire (35 C minimum). For 50 to 75 ft, use no. 16

AWG insulated wire (35 C minimum). For over 75 ft, use

no. 14 AWG insulated wire (35 C minimum).

Set heat anticipator settings as indicated in Table 3.

Settings may be changed slightly to provide a greater

degree of eomfort for a partieular installation.

Refer to accessory remote control panel instructions

as required.

THERMOSTAT ASSEMBLY

REMOVABLE JUMPER

I

h

PH

r

^ 1^ ^

^

[

r

] [

b

] 1 ^ Й Й ] Й [ ^ [ £ ] [

x

] [

h

] [ 1 ] [ K I

o

liJ

q

:

<

(r.

e >

z>

_j

CD

s

LOW-VOLTAGE TERMINAL BLOCK IN UNIT CONTROL BOX

Fig. 11 — Field Control Thermostat Wiring

Step 7 — Make Outdoor Air Inlet Adjustments

MANUAL OUTDOOR AIR DAMPER — All units

(except those equipped with a faetory-installed eeono-

mizer) have a manual outdoor air damper to provide

ventilation air. Damper ean be preset to admit up to 25%

outdoor air into return air compartment. To adjust,

loosen seeuring screws and move damper to desired

setting then retighten screws to seeure damper (Fig. 12).

OPTIONAL ECONOMIZER

Enthalpy Control Setting (loeation is shown in Fig. 13) —

For maximum benefit of outside air, set enthalpy control

to the A setting (Fig. 14).