Carrier 50DP016 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

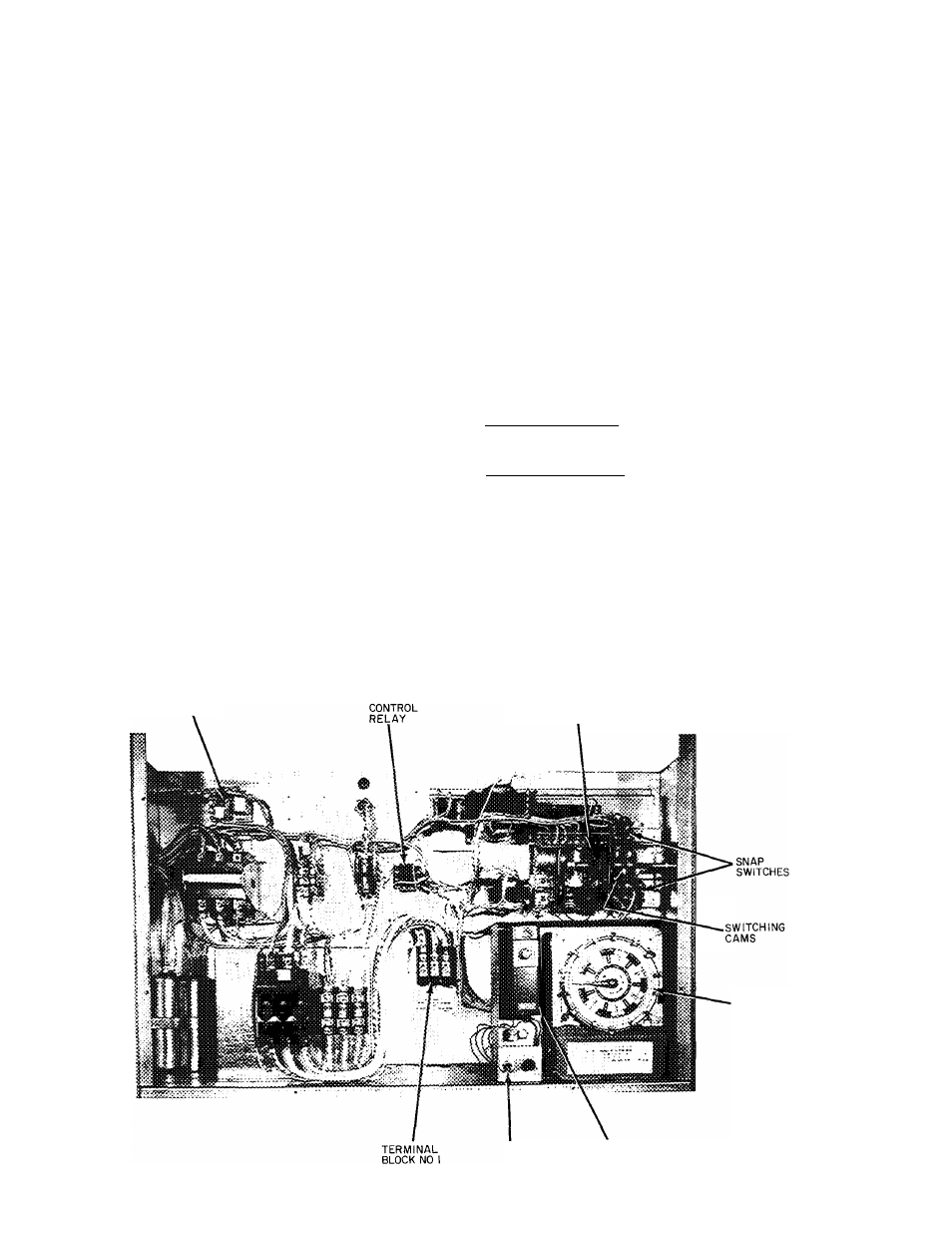

Variable Volume Units — Units suitable for use with

variable volume air handling systems are equipped with 2

electric unloaders on the compressor. The control panel

for these units (Fig. 18) consists of a step controller, a

proportional thermostat, a 7-day timer and a power

switch.

Before starting unit, open compressor service valves

and liquid line shutoff valve. Be sure compressor crank-

ease heaters have been on for 24 hours and that crankcase

oil level indicates half full.

CONTROL SEQUENCE CHECKOUT

1. Turn on unit main power supply. Be sure unit is ready

to operate.

2. Set variable volume control panel POWER switch

at ON.

3. If supply air leaving unit is above 50 F (or other field-

set temperature), step controller will operate to de

energize compressor unloader solenoids (compressor

loads up) until set temperature is achieved. An interval

of 13.5 minutes is required to maximum loading

position. Refer to unit label diagram for unloader

sequencing. Also see Fig. 19.

4. Step controller, 7-day timer and proportional thermo

stat are factory set and adjusted. If other settings

or changes in adjustment are required, refer to dis

cussion of these items.

SEVEN-DAY TIMER ADJUSTMENT — Factory

settings are ON — 6:30 A.M.; OFF — 7:30 P.M. for each

of 7 days.

1. On the timer dial face (Fig. 18), loosen the thumb

screws which position the system ON and OFF

trippers.

2. Set trippers at desired system ON and OFF time

settings and tighten thumbscrews. Skipping a day(s) is

accomplished by removing trippers from the dial.

3. Set the timer by turning the dial face

clockwise

until

fixed pointer indicates correct day and time.

Do not

turn dial face counterclockwise. Do not move fixed

pointer.

PROPORTIONAL THERMOSTAT — The propor

tional thermostat. Fig. 18, monitors temperature of the

conditioned air leaving unit. On signal from the thermo

stat, sequence motor operates cam switches to load or

unload compressor to maintain thermostat setting.

Thermostat is factory set at 50 F ± 6 F but may be reset

between 0°F and 100F as follows:

Temperature Setting — Turn knob on front of case until

pointer indicates desired set point temperature. This is

the center point of proportional range.

Range Adjustment — Remove cover and turn adjustment

wheel until pointer indicates desired range.

If sequencer motor shaft constantly moves back and

forth, increase proportional thermostat range (about 5 F

at a time) until system is stable.

CYCLE-LOC

STEP

CONTROLLER

POWER

SWITCH

PROPORTIONAL

THERMOSTAT

SEVEN

DAY

TIMER

Fig. 18 — Control Panel, Variable Volume Limits

12