Carrier 50DP016 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

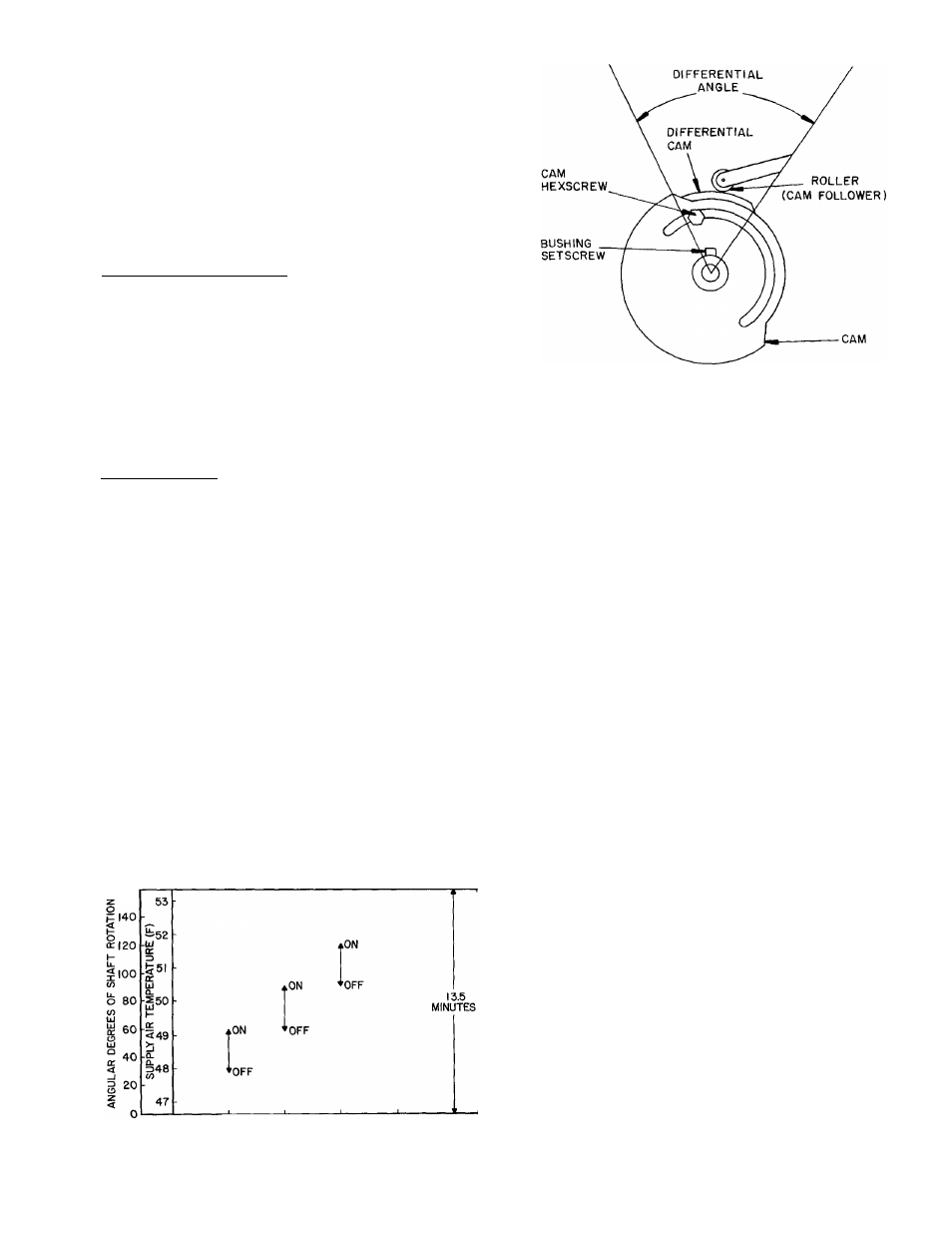

STEP CONTROLLER — The step controller consists of

a reversible electric motor which drives a set of cams that

activate up to 5 snap-acting switches. Each cam is adjust

able to operate at any point on the 160 angular degrees of

camshaft rotation. The differential of each system may be

adjusted from a minimum of 5 angular degrees to a maxi

mum limited only by the 160 angular degrees of camshaft

rotation.

Rotational direction is controlled by the proportional

thermostat through the step controller feedback poten

tiometer and balancing relay.

Determining Switch Settings — Switches are factory set

at angular settings as shown m Fig. 19 (also shown on unit

label diagram). To reset, if desired, determine angular

differential for each switch and between switches. Then

determine minimum differential or throttling range of

proportional thermostat to provide desired step con

troller differential or throttling range. This range should

be wide enough to prevent rapid cycling from one

capacity step to another. Then adjust cams to new settings

as required.

MAKE

POINT

BREAK

POINT

Fig. 20 — Step Controller Cam Adjusting

Details (Motor End View)

#

#

Cam Adjustments — The step controller is shipped with

cams set to operate switches (i.e. compressor unloaders)

as shown in Fig. 19. All switches are closed (compressor

unloaded). The shaft is positioned all the way counter

clockwise (as viewed from motor end).

Using the following procedure, first adjust all operating

points in one direction of motor drive. Then reverse

motor direction and adjust switch differentials. Use

potentiometer wiper as an approximate indicator of

angular adjustments using angular displacement scale

mounted on potentiometer back plate. Also see Fig. 20.

160

I

2

3

4

STEP CONTROL SWITCH

Fig. 19 — Step Controller Sequence

1. Loosen all bushing setscrews with a 1/16-in. Allen

wrench. Loosen all cam hex screws with a 3/16-in.

open-end wrench.

If setscrews are not accessible from top of controller,

operate motor to rotate cams and bushings by shorting

terminals R and B for counterclockwise rotation and

terminals R and W for clockwise rotation.

2. Momentarily de-energize motor to permit motor to

recycle to start position. Jumper terminals R and W to

run motor camshaft to desired position for operating

first switch. Stop motor in this position by removing

jumper between terminals S and T.

3. Starting with first switch, turn cam clockwise until

switch makes an audible “click” as roller moves up cam

rise to higher level. This is the operating point. Lock

bushing setscrews.

operating point of each of remaining switches in

manner. Advance motor by momentarily jumper-

Set

like manner.________

ing terminals S and T.

5. Set switch differential by reversing motor (short

terminals R and B) and running it to desired break

point. Stop motor at this point by de-energizing power

at LI (POWER switch off). Start at last switch and

progress to first switch.

Move differential cam clockwise so that roller is on

high part of cam. Be sure that switch is at make

position. To check this, manually lift roller assembly

to make switch. Move differential cam counterclock

wise until roller drops to low level of cam. At this

point, switch should break. Lock the hex screw.

6. Check settings by performing Control Sequence

Checkout.

7. If 115-volt to step controller is de-energized, timer

recycles to start point when power is restored.

13