Carrier 50BK User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 2 — Setscrew Torque Requirements

A VsfmCAL DfSC^íARS£

BOLT SIZE

1 RECOMMENDED

(in.)

TORQUE (Ib-ft)

%

1 15-18

Vs

1 22-25

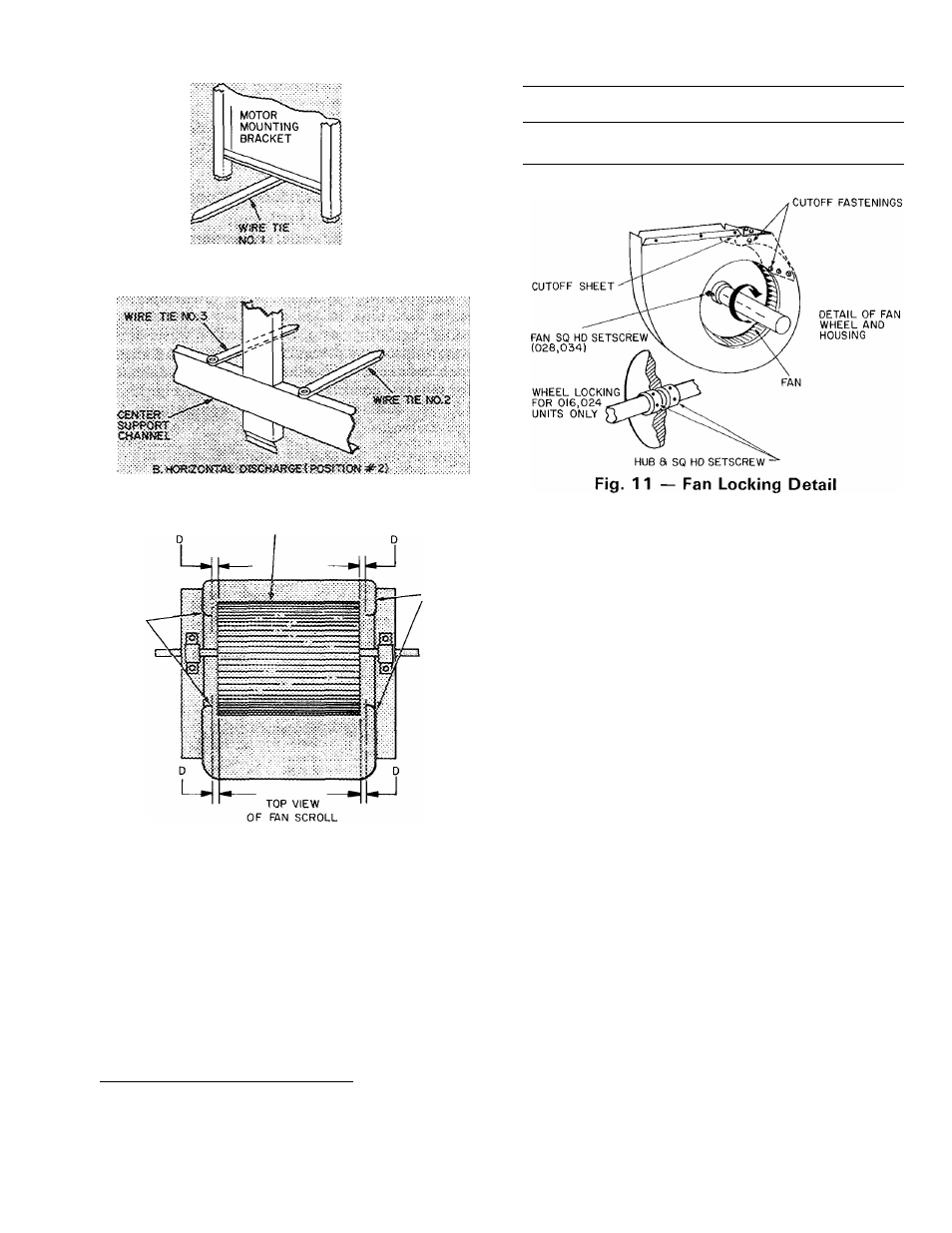

Fig. 9 — Wire Tie Locations

W H E E L

#

VENTURI

7SCROLL

DIMENSION "

d

"

MUST BE EQUAL ALL AROUND

Fig. 10 — Horizontal Wheel Centering

Adjust as follows:

Units 50BJ,BK0I6 and 024

1. Loosen setscrews holding wheel support to shaft

(Fig. 11).

2. Center the wheel by sliding it horizontally

(Fig. 10).

3. Retighten setscrews.

Units 50BJ,B1C028,034,044,054 and 064

1. Loosen fan wheel square head setscrews on each

side of fan support (Fig. 11).

2. Center wheel by sliding it horizontally (Fig. 10).

3. Retighten locking setscrews to torque specified

in Table 2.

CONCENTRIC

ALIGNMENT—Shaft

and

wheels

must be concentrically centered with the venturi or

air inlet of the fan housing.

ALL UNIT SIZES — Bearings are bolted to sup

ports.

To

correct

shaft

and

wheel

concentric

misalignment:

1. Loosen bearing support bolts and shim or move

as required.

2. Retighten bearing support bolts,

HORIZONTAL SHAFT ALIGNMENT (All

Units) — If the shaft has moved and all wheels are

off horizontal center, recenter the shaft as follows:

1.

Loosen setscrews holding bearing locking collar

at each end of shaft.

2.

Slide shaft and wheel assembly horizontally until

wheels are horizontally centered (Fig. 10).

3.

Slide the bearing locking collars against the

bearing race; turn in direction of shaft rotation

until tight.

4. Retighten locking collar setscrews.

FAN,

PULLEY

AND

BELT

ADJUSTMENT

—

Refer to the Service section entitled Indoor-Air

Fan Adjustment.

Step 9 — Install Field-Fabricated Ductwork

Connect ducts to unit, using flexible connections

as required. Duct angles are supplied with each

50BJ,BK044,054 and 064 unit. Install duct angles

at duct openings using flexible connections. Connect

supply ducts to flanges. Supply ducts should not be

manifolded together for at least 4 feet.

Attach ductwork to building structure and in

sulate. Add a vapor barrier to prevent sound trans

mission and vapor condensation.