Indoor-air fan motor removal, Sim oif artd lockout ouit power swply, Biotor î3ao«îî£&, place a pjece of i^wooá over – Carrier 50BK User Manual

Page 18: A caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Evaporator

Coil — Protect coil when working

inside unit.

(See screened CAUTION note, page 15.)

Remove dirt and debris from evaporator coil as

required. Clean with a stiff brush, vacuum cleaner

or compressed air. Straighten mashed or bent coil

fins with a fin comb of the correct spacing. Table 1

lists the fins per inch for each coil.

Water-Cooled Condenser(s) may require clean

ing of scale (water deposits). Contact local water

treatment company for best results.

Air-Cooled

Condensers

—

Periodically

inspect

and

clean

depending

on

operating

conditions.

Follow the service instructions provided with the

air-cooled condenser used.

Sight Glasses are provided at the inlet of each

expansion valve. Units may be field charged by

using the sight glass (see Charging the System).

'Charging the System

UNITS

WITH

WATER-COOLED

CONDENSER

(50BJ) — Units are shipped with a full operating

charge of refrigerant. If recharging is necessary

(complete charge lost) weigh in amount of refrig

erant indicated on unit nameplate and Table 1.

If unit has a partial charge, unit may be charged

with sight glass using standard charging techniques.

See Carrier Standard Service Techniques Manual

entitled

Chapter

1,

Refrigerants

for

applicable

procedures.

Adjust

the

water

regulating

valve

to

proper

saturated condensing temperature (168 to 226 psig).

UNITS

WITH

AIR-COOLED

CONDENSER

(50BK) — Units are shipped with a holding charge

only. To charge:

1. Open suction and discharge line service valves.

2.

Blow holding charge, evacuate and leaktest

system.

3.

Add sufficient refrigerant vapor to permit con

tinuous operation after starting unit.

4.

Start unit per Start-Up Section; then, using

standard charging techniques, add refrigerant as

required

to

maintain

normal

operating

conditions.

Use charging chart supplied with condenser. If

information is not available, block off enough of

condenser coil to maintain 220 psig discharge

pressure and charge to a clear sight glass.

Indoor-Air Fan Motor Removal

Sim oif artd lockout ouit power swply.

A CAUTION

ALL 50BJ,BK UNITS — Remove motor as follows:

1. Remove unit access panel and cover of motor

junction box.

2. Disconnect motor wires and remove conduit

connection.

3. Remove motor bolts and slide motor over so

that fan belt can be removed.

4. Disconnect motor ground wire (if present) and

remove motor.

TO REINSTALL MOTORS — Reverse the above

procedures. Align pulleys and adjust belt tension as

described

in

the

section,

Indoor-Air

Ean

Adjustment.

Pressure Relief Devices — The 50BK (condenser

less) and 50BJ,BK044-064 units are equipped with

a fusible-plug type safety relief device on the com

pressor. The relief setting is 197 or 203 E on all units.

All 50BJ (water-cooled) units have a frangible

disc on each condenser. Disc setting is 385 ± 5% psig.

^Crankcase

Heaters

are

supplied

on

all

50BK

(condenserless) units and on 50BJ044-064 water-

cooled units.

The heater reduces the possibility of liquid refrig

erant from accumulating in the compressor crank

case during extended shutdown periods. Heater is

automatically energized whenever unit main power

is on and compressor is stopped. Heater is de

energized when compressor starts.

Do not shut off unit main power supply for an

extended period except for servicing unit. After an

extended shutdown period, turn power supply on at

least 24 hours prior to starting compressor.

If 50BJ units are installed in unheated rooms,

they should be equipped with crankcase heaters. All

units equipped with crankcase heaters require 24

hours warm up time.

High-and Low-Pressure Switches — The high-

pressure switch is located in the electrical panel.

The

low-pressure

switch

is

located

on

top

of

compressor.

Time

Guard®

Control

Circuit

provides

auto

matic

reset

protection

(except

circuit

breaker),

time delay in starting and controlled cycling. If

compressor shuts down for any reason, the control

circuit prevents restart for time periods as follows:

Biotor î3ao«îî£&, place a pjece of i^wooá over

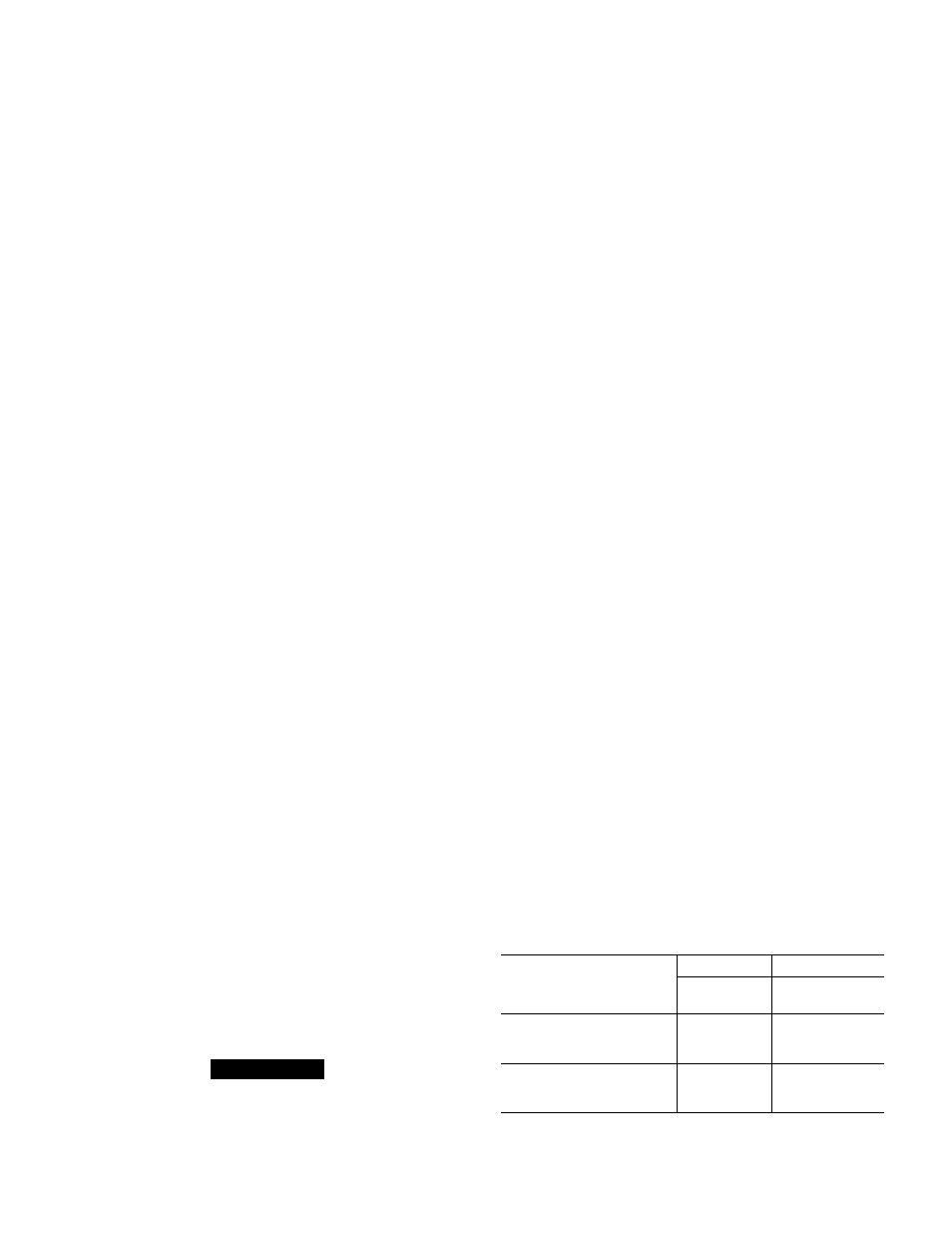

UNIT

50BJ.BK

CIRCUIT

NO.

A

B

Full Cycle

(minutes)

Delayed Start

(seconds)

016

1

5

15

024,028,

1

64

19

034

1 2

5

15

044,054

1

2

5

15

064

1 1 and 2

64

19

Column B shows time delay between compressor

starts under normal thermostat cycling.

17