Step 13 — install unit drain line, Fig. 18 — condensate drain – Carrier 50BK User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 4 — Recommended Line Sizes (in.)

(50BK Condenserless Models)

HG — Hot Gas Line (OD in ]

L — Liquid Line (OD in )

‘Sweat connections

UNIT

50BK

CONN.

LENGTH OF LINE (ft)

SYSTEM

SIZES*

20

40

60-80

L

HG

L

HG

L

HG

L

HG

016

—

%

^Ve

Ve

1'/s

ys

P/s .

ys

P/s

024

1 & 2

%

Vs

Y

b

ys

Ye

P/s

ys

P/s

028

1

%

^Vв

Va

1'/s

V

b

p/s

ys'

p/s

2

Ys

ys

Y

b

ys

Ya

p/s

Ps

p/s

034

1 & 2 1 %

r/s

Y

b

1

V

b

Va

p/s

ys

p/s

044

1 & 2

%

IVs

V

b

V/a

V

b

p/s

ys

p/s

054

1 & 2

%

lys

V

b

P/s

V

b

p/s

ys

p/s

064

1 & 2

ys

^Уe

V

b

P/s

Va

p/s

ys

p/s

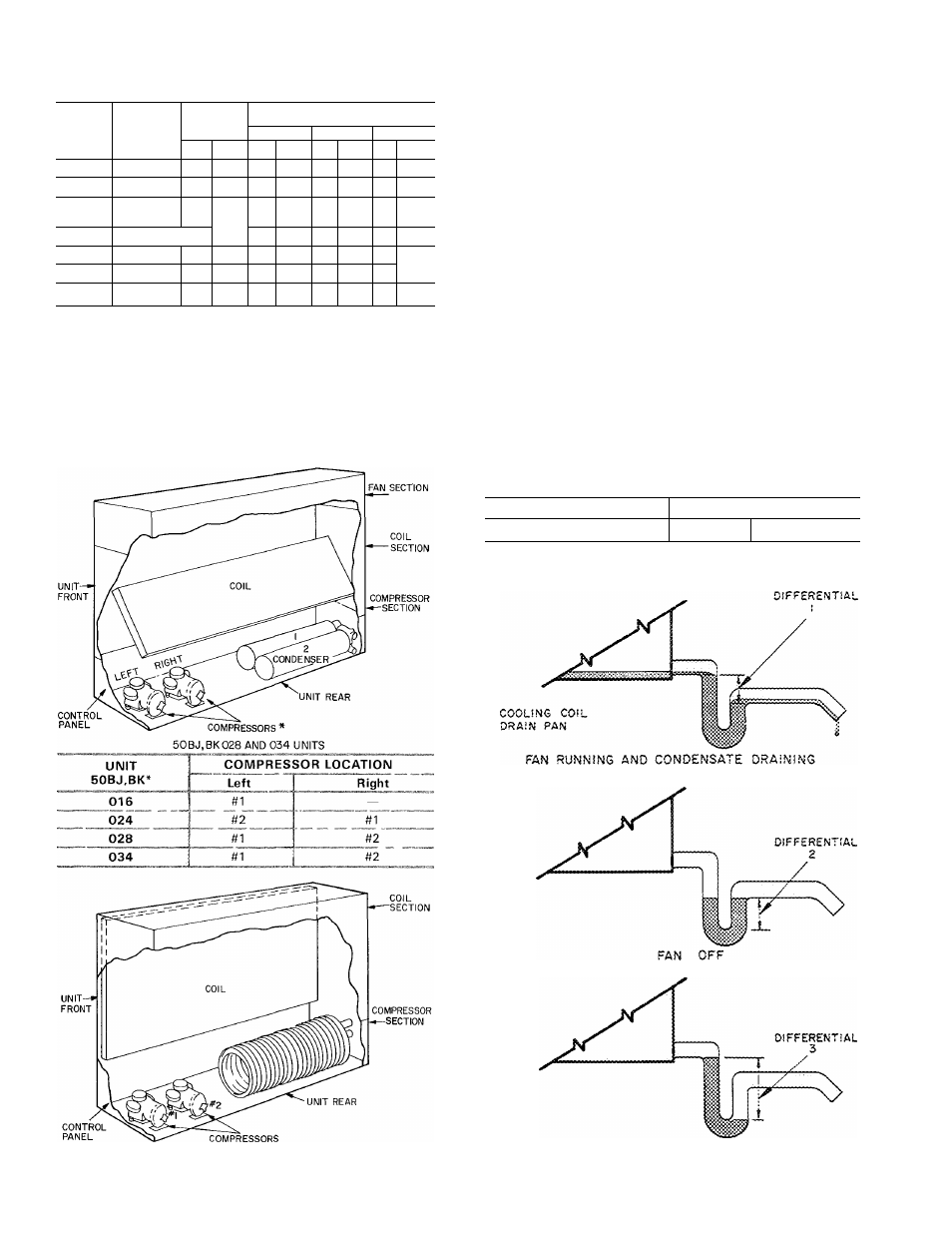

Step 13 — Install Unit Drain Line

Install a trapped condensate drain line at unit

drain

connection

(Fig.

12).

The

drain

requires

standard pipe connected to condensate pan nipple

as shown in Table 5. Figure 18 shows proper

trap design.

Determine design negative static pressure. This

pressure is not the same as fan total pressure,

which includes pressure losses downstream as well

as upstream from the indoor air fan. Always assume

the worst conditions, such as having return air

filters clogged with dirt.

Referring to Fig. 18, Differential 1 must be equal

to or larger than negative static pressure at design

operating conditions. Store enough water in trap to

prevent losing seal (Differential 2). This differential

must be equal to or larger than one-half the maxi

mum negative static pressure. When the fan starts.

Differential 3 is equal to the maximum negative

static pressure.

Table 5 — Condensate Drain Connections (in.)

UNIT SIZE :

016,024

028,034

044,054,064

PIPE SIZE ;

1

P/4

P/2

50BJ.BK044-064

UNITS

Fig. 17 — Refrigerant Systems (016-064)

TRAP CONDITION WHEN FAN STARTS

Fig. 18 — Condensate Drain

II