Fig. 24 — fan belt adjustment, Lubrication — shut off power protect, Shut off unit power – Carrier 50BK User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 3 — Matched Set of Belts — Always use

matched set of belts.

NEVER mix new and used

belts andjor mix belts from different manufacturers.

Step 4 — Belt Installation:

a.

Move pulleys together to facilitate belt installa

tion.

NEVER pry or roll belt on to pulleys as this

may cause serious damage to belts.

b.

Work belts around pulleys by hand. All belts

should be slack on same side of drive.

Mixing

slack and tight sides together may result in

.serious damage to belts when drive is tensioned.

THIS

OR THIS

NEVER THIS

Fig. 24 — Fan Belt Adjustment

c.

Move pulleys apart until belts are snug. Make

preliminary check of sheave and shaft alignment.

Operate drive at no load for several minutes to

seat belts and then check belt tension.

Excessively

high or low tensions adversely affect the life and

operation of V-belts.

d.

Check sheave and shaft alignment after belt

tension is applied.

PULLEY ALIGNMENT —

Shut off unit power

Make sure motor and fan shafts are parallel.

Align

shafts

by

loosening

motor

on

mounting

bracket if required. Then loosen fan pulley set

screws, slide pulley along fan shaft and align with

straightedge as shown in Fig. 25.

PULLEYS

/

\ SETSCREWS

MOVABLE F

langes

A

/ ■

STRAIGHT EDGE MUS

t

/

SE PARALLEL

WITH BELT

/

A

l

/

: SETSCREWS--

nXED FLANGES

SINGLE-GROOVE T-WO-GRC'O'VE

MOTOR a FAN SHAFTS

' ^ MUST BE PARALLEL

Fig. 25 — Indoor Air Fan Pulley

Adjustment and Alignment

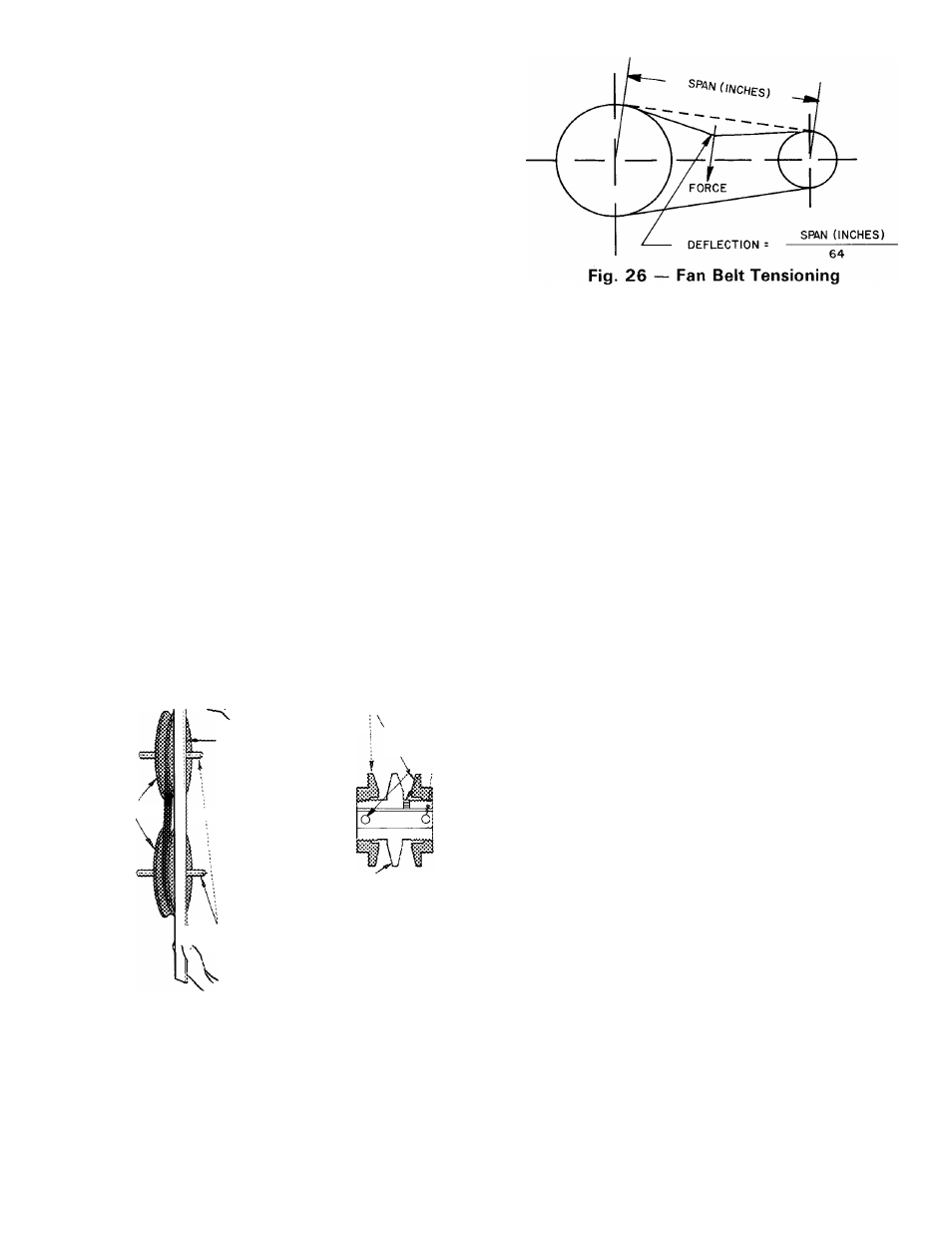

TENSIONING (See Fig. 26) — Use the following

steps when adjusting belt tension:

Step 1 — Measure belt span in inches.

Step 2 — Use spring scale at center of span to deflect

belt 1/64 inch for every inch of span length. Record

scale reading.

Example: For span of 10 inches — deflection will be

10

5 . .

tt

or inch.

64

32

Step 3 — Spring scale reading should be in range of

12 to 18 pounds. Maximum tension for a new belt

is 18 pounds.

Step 4 — Adjust tension to maximum after 15

minutes. Check belt tension after 2 to 4 hours of

operation.

Step 5 — After 24 to 48 hours of operation, check

drive to see if normal tension is obtained.

Exces

sively high or low tension will adversely affect life

and operation of V-belt.

Lubrication —

Shut off power

Protect

coil from damage.

Fan motor bearings are factory lubricated and

will need no lubrication for the first 5 years of

operation (3 years with continuous service or ex

cessively dirty conditions).

Inspect bearings and relubricate or replace as

required.

Follow

manufacturer’s

instructions

for

lubrication of special field-supplied motors.

Fan shaft bearings on 50BJ,BK016 and 024 units

are lubricated for the life of the bearings. Bearings

for 50BJ,BK028 thru 064 units have grease fittings.

On 50BJ,BK044-064 units the fan shaft universal

joint requires the same lubrication as the bearings.

Lubricate annually with a good grade of mixed base

grease or lithium base grease with rust inhibitor.

Add grease until air bubbles form under the seal.

Do not overgrease.

Return-Air Filters — Inspect filters twice monthly

and replaee as often as required by operating condi

tions. Filter type and size is given in Table 1.

If field-supplied, cleanable filters are used, flush

them with hot water or steam, or soak them in a

mild solution of soap or detergent and water. Refer

to filter manufacturer’s instructions as applicable.

Never operate the unit without return-air filters

in place.

Condensate Drains — Clean drain line and unit

drain pan at start of each cooling season. Check

flow by pouring water into drain. Be sure trap is

filled to maintain air seal (Fig. 18).

16