Start-up, Prior to unit start, Control sequence checkout – Carrier 50BK User Manual

Page 15: Start-up ,15, Prior to unit start control sequence checkout

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

START-UP

General — The 50BJ,BK. units are designed for use

in Modu-Vac Variable Air Volume Systems using

Carrier 37A Moduline® and 35B Modubox Air

Terminals. For air terminal installation and adjust

ment, refer to 37 A or 35B literature as required.

CAPACITY CONTROL — The units are equipped

with electrie unloaders on the lead compressor

(Fig. 17) and hot gas bypass on the no. 1 refrigerant

system. (Size 016 units have only one refrigerant

system.)

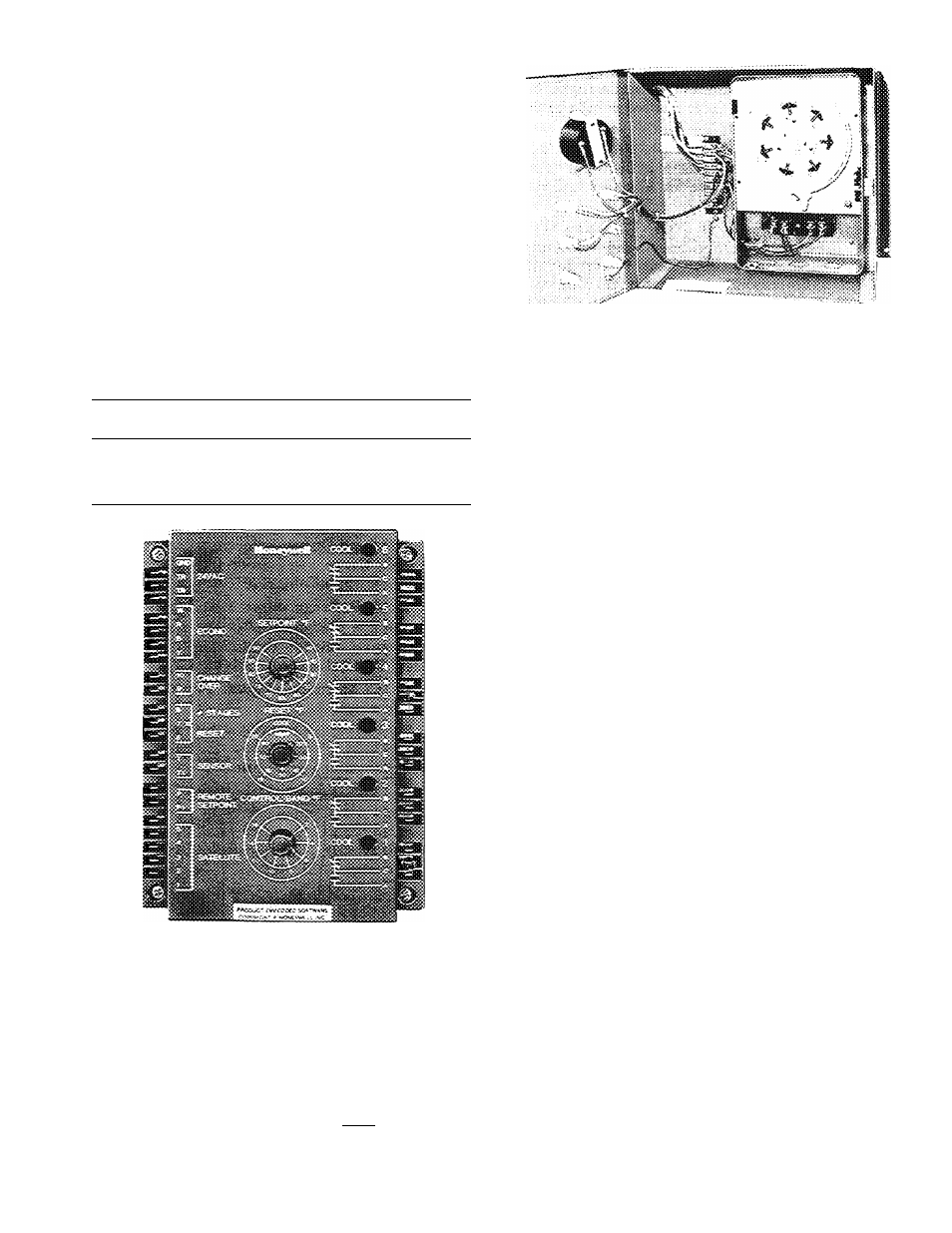

Unit capacity is monitored and controlled by a

Honeywell W7100 microprocessor (Fig. 20). This

controller provides the number of capacity control

steps as shown in Table 8.

Table 8 — Capacity Control Steps

UNITS

I CAPACITY CONTROL

50BJ.BK

I (No. Steps)

016

I 3

024,028,034

6

044

4

054,064

6

Fig. 20 — Honeywell Microprocessor

TIMER CONTROL — Carrier strongly recom

mends use of an accessory timer control panel with

the 50BJ,BK units. Installation and adjustment of

this device (Fig. 21) is covered in separate Installa

tion, Start-Up and Service Instructions included in

the accessory package.

If accessory timer is not used, install field-installed

manual switch between TB3 terminals [~T~| and

in the variable volume eontrol box for the 016-034

units. Switeh is factory-installed on the 044-064

units.

Fig. 21 — Accessory Timer Control Panel

MOISTURE INDICATORS are located ahead of

thermal expansion valves. They must be full of

liquid

to

properly

indicate

moisture

content.

Operate system for 30 minutes before determining

moisture content.

SERVICE VALVES (50BK) — Valves use teflon

seat washers to ensure position seal with minimum

stem torque (10 Ib-ft max). Do not overtighten valve

stem. Use wet rag on valve when soldering. If refrig

erant has been lost, midseat valve. Always replace

stem cap.

Prior to Unit Start

1. Clean and inspect the unit.

2.

Open (backseat) compressor service valves and

liquid line shutoff valves. Replace and tighten

valve caps to prevent leakage.

3.

On 50BK (air-cooled condenser) units, turn on

indoor fan motor circuit breaker. Check that

compressor crankease heaters are energized and

crankcase oil level is half full.

4.

Leave crankcase heaters energized for 24 hours

to ensure safe oil/ refrigerant mixture in crank

cases for unit start-up.

Control Sequence Checkout

1.

Perform all applicable steps described above

under Prior to Unit Start.

2. Turn on unit main power supply.

^3. Set the control band knob on microprocessor

(Fig. 20) at 2.

4. Turn on indoor fan motor circuit breaker.

5.

If unit is equipped with accessory timer control

panel and 7-day clock is not calling for cooling,

turn on unit by overriding clock with manual

bypass

switch

(see

Start-Up

General

section

entitled, TIMER CONTROL).

6. Close compressor circuit breakers.

7.

Check for cooling by turning microprocessor

SETPOINT knob to 40 F. Light-emitting diodes

14