Control sequence – Carrier 50BK User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CONTROL SEQUENCE

All 50BJ,BK Units — The indoor fan circuit

breaker (IFCB) must be closed for the control

circuit to be energized. When breaker is closed, the

SYSTEM light will be on.

The 044-064 units are equipped with a switch

labeled STANDBY. When switch is closed, the

indoor fan contactor (IFC) is energized and the

indoor fan will start and run continuously. A light

labeled FAN will come on. To use accessory timer

control, switch must be put in STANDBY position.

All units are equipped with the improved Honey

well W7100 discharge air controller. Controller has

3 control knobs: set point, reset and control band.

Controller regulates the leaving air temperature to

the set point. A setting below 50 F may decrease

unit efficiency due to use of hot gas bypass at light

loads. The reset knob adjusts reset control range

from 5 F to 20 F. The reset feature requires field-

supplied components and wiring. The control band

knob adjusts controller for the required number of

stages. The control band should be set at 6 F for the

016-034, 054 and 064 units, and 8 F for the 044 units.

Increasing control band setting above these recom

mended settings will decrease compressor cycling

and

increase

leaving

air

temperature

variations.

Decreasing setting will

not

reduce discharge air

temperature variations but will increase compressor

cycling.

The controller is also factory equipped with 2

fixed resistors. One resistor corrects for the number

of steps. This is done by placing a 1/4-watt, 5%-

m

8

on micro-

resistor

across

terminals

m

and

processor. A 3-stage, 300-ohm resistor is used on the

016 unit. A 4-stage, 400-ohm resistor is used on 044

units and a 600-ohm resistor is used on 024-034,

054 and 064 units. A second 510-ohm resistor is

connected between terminals 0 and [V] to indi

cate unit does nt have an economizer. These units do

not have a factory-supplied eeonomizer. If a field-

supplied economizer is added, remove the 510-ohm

resistor.

Consult

Carrier

Corporation

for

more

details.

If the discharge air deviates 1°F above or below

the control band while unit is running, a cooling

capacity stage will either be added or removed

according to the loading sequence table found on

page 18. Additional capacity steps will be turned on

or off until discharge air temperature is within

control band or is charging at a rate that will allow

it to be within control band within 10 minutes. The

controller also has a fixed guaranteed minimum

on and off time of 4 minutes to prevent compressor

cycling.

These units are equipped with a Time Guard®

circuit. This circuit prevents compressor no. 1 from

restarting until 4 minutes, 45 seconds have elapsed

from last shutdown. Compressor no. 2 will not

restart until 6 minutes, 10 seconds have elapsed.

Each compressor is equipped with a high-pressure

switch (HPS), discharge gas thermostat (DGT) or

internal

protection

(IP)

and

low-pressure

switch

(EPS). If any of these “trip”, the compressor will

shut down. If, after 4 minutes, 45 seconds for com

pressor no. 1 and 6 minutes, 10 seconds for compres

sor no. 2, the switch resets, compressor no. 1 will

restart within 15 seconds and compressor no. 2

within 19 seconds.

The 50BK condenserless units are equipped with

a liquid line solenoid (ELS). When a stage calls for

compressor shutdown, the liquid line solenoid will

close first. The compressor will continue to run until

the low-pressure switch opens.

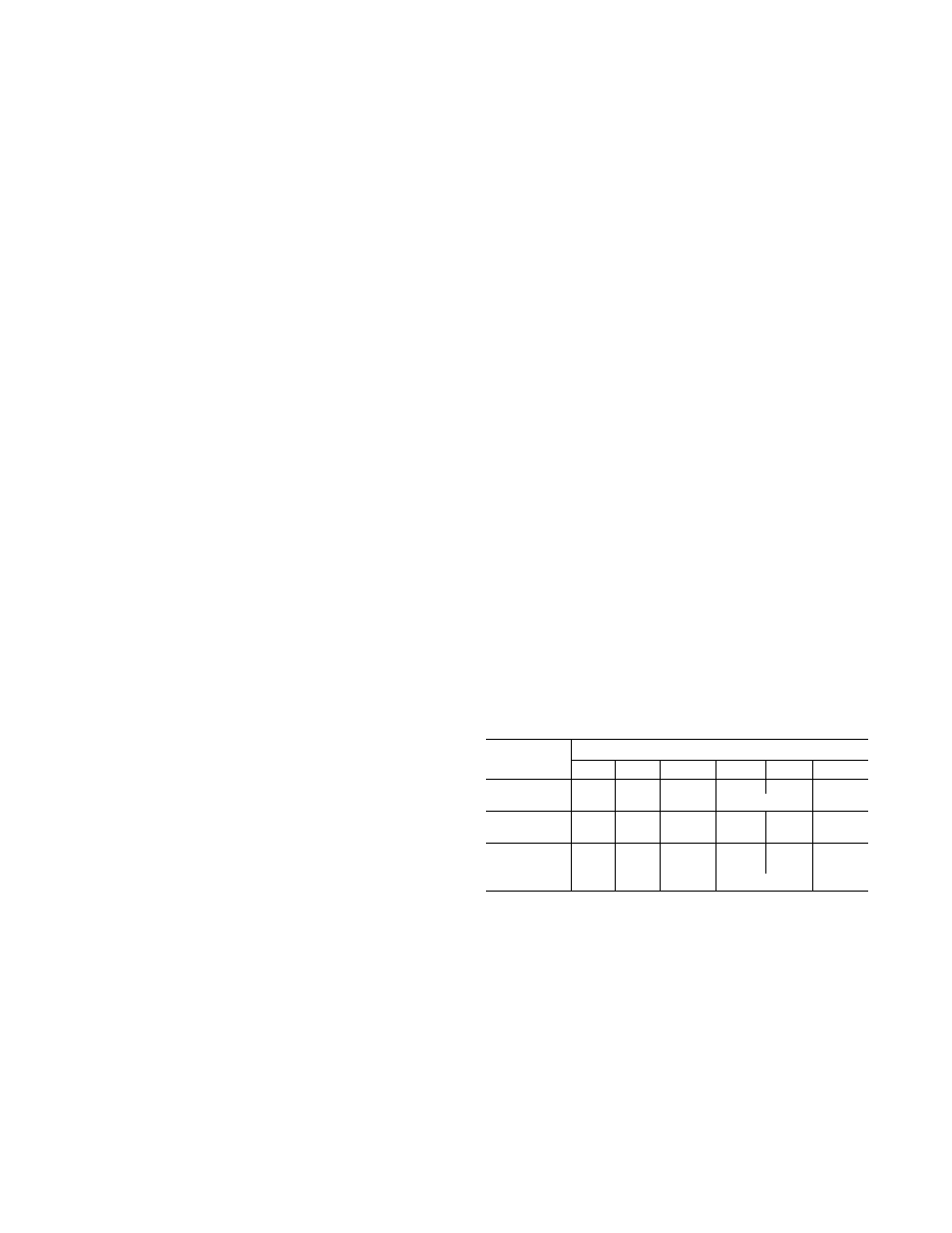

Loading Sequence

MODEL

STAGE

50BJ.BK

1

2

3

4

5

6

016

33%

67%

100%

—

—

—

024

17%

34%

50%

67%

84%

100%

028

17%

34%

50%

67%

84%

100%

034

17%

34%

50%

67%

84%

100%

044

25%

50%

75%

100%

------

—

054

19%

38%

57%

63%

84%

100%

064

17%

34%

50%

67%

84%

100%

18