Carrier 50YQ User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 4 — Service Data

UNIT 50YQ

024

030

036

042

048

060

R-22 CHARGE* (lb)

54

5 7

5 15

6 7

7 3

8 6

Refrig Control

AccuRater^M

INDOOR FAN

Centrifugal — Direct Drive — 3-Speed

Rpm

1100/1050/900

Diameter (in.)

9

9

9

10

10

10

Width (in.)

7

7

9

9

9

10

Range (cfm)

833-1040

1000-1250

1183-1480

1367-1708

1633-2040

1800-2250

Motor Hp

1/5

1/5

1/3

1/2

1/2

3/4

OUTDOOR FAN

Propeller — Direct Drive

Cfm

2500

2500

2500

2700

3200

3600

Rpm

1050

1050

1050

1050

1050

1050

Diameter (in.)

20

20

20

20

20

20

Motor Hp

1/5

1/5

1/4

1/4

1/4

1/4

"Factory refrigerant charge

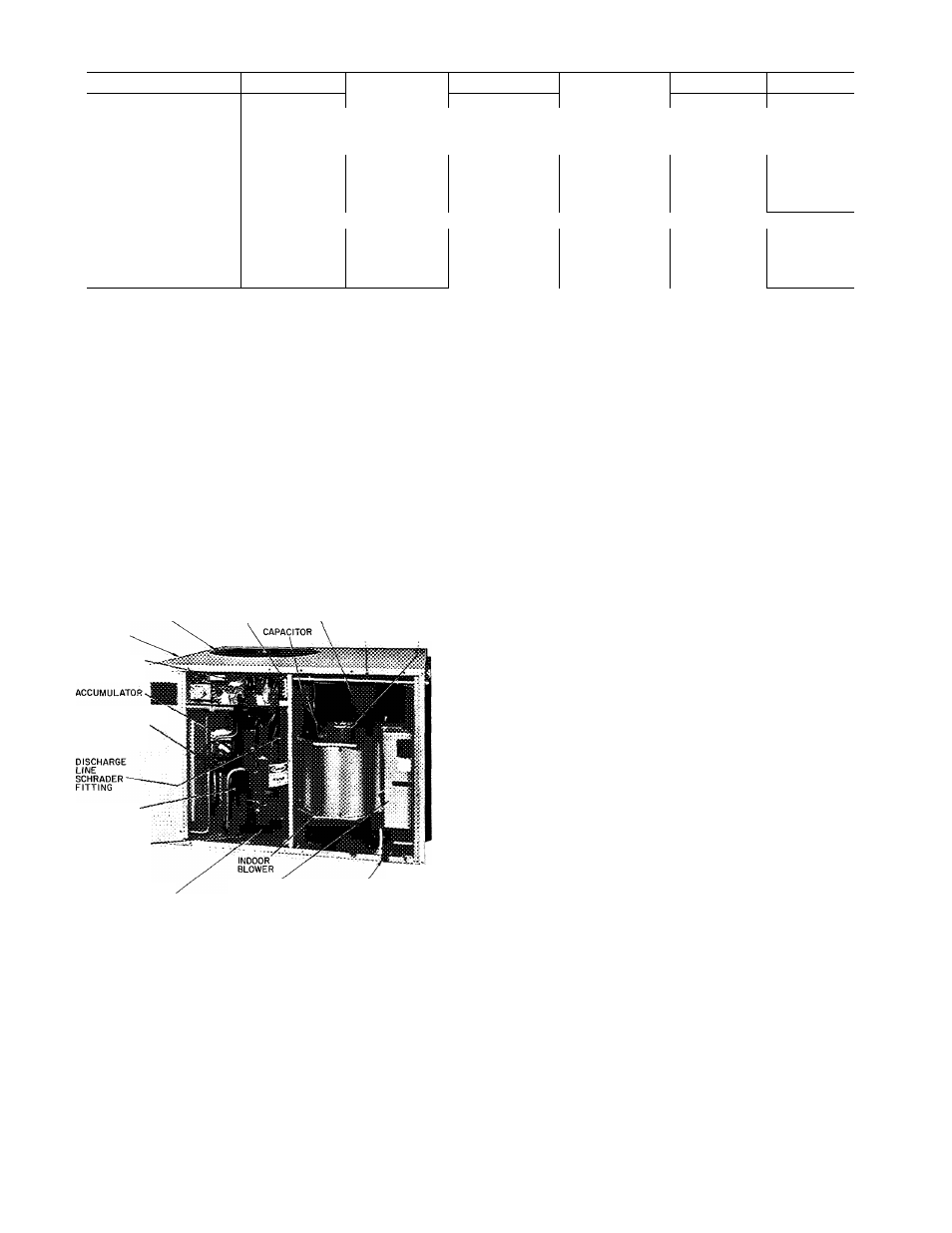

Unit refrigerant system is factory charged. When

recharging is necessary, weigh in total charge indi

cated in Table 4. (Charge must be weighed in during

heating season.) Remove any refrigerant remaining

in system before recharging. If system has lost com

plete charge, evacuate system to 500 microns

(29.7 in. vacuum) before recharging. Service port

connections are provided on unit suction and dis

charge lines for evacuation and charging. (See

Fig. 10 for service port location.) Dial-a-charge

charging cylinder is an accurate device used to re

charge systems by weight. These eylinders are avail

able at refrigeration supply firms.

OUTDOOR FAN

DISCHARGE GRILL

CONTROL WIRING

TERMINAL BLOCK

TOP COVER

UNIT CONTROL

BOX

REVERSING

VALVE

\

INDOOR

INDOOR BLOWER

COIL

MOTOR I

CONTROL WIRING

CONDUIT

SUCTION LINE'

SCHRADER

FITTING

COMPRESSOR

HOLD DOWN

BOLTS

ELECTRIC

COMPRESSOR

a

I

s

EMBLY

CONDENSATE

\

DRAIN LINE LINEWIRING

SPLICE BOX

Fig. 10 — Component Location (Typical)

To check and/or adjust charge during cooling

season, use correct Cooling Cycle Charging Chart

(Fig. 11 thru 16) and follow Charging Chart Method

below. The charging chart may also be used as an

alternate method of recharging system.

To check system operation during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 17 thru 22). These charts indicate whether a

correct relationship exists between system operating

pressures and air temperatures entering unit. If

pressure and temperature lines do not intersect on

chart, the system refrigerant charge may not be cor

rect or other sysem abnormalities may exist. Do not

use Operation Check Charts to adjust refrigerant

charge. Weigh charge into system.

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking

charge,

and

after

each

charge

adjustment.

2. Measure suction pressure by attaching a gage to

unit suction service port. (See Fig. 10 for correct

service port location.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature. Use service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor fan coil.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor

air wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than ehart

pressure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

7 8 1