Accurater™ (dual-piston type) servicing, Fig. 23 — accurater^^ (dual-piston) components – Carrier 50YQ User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

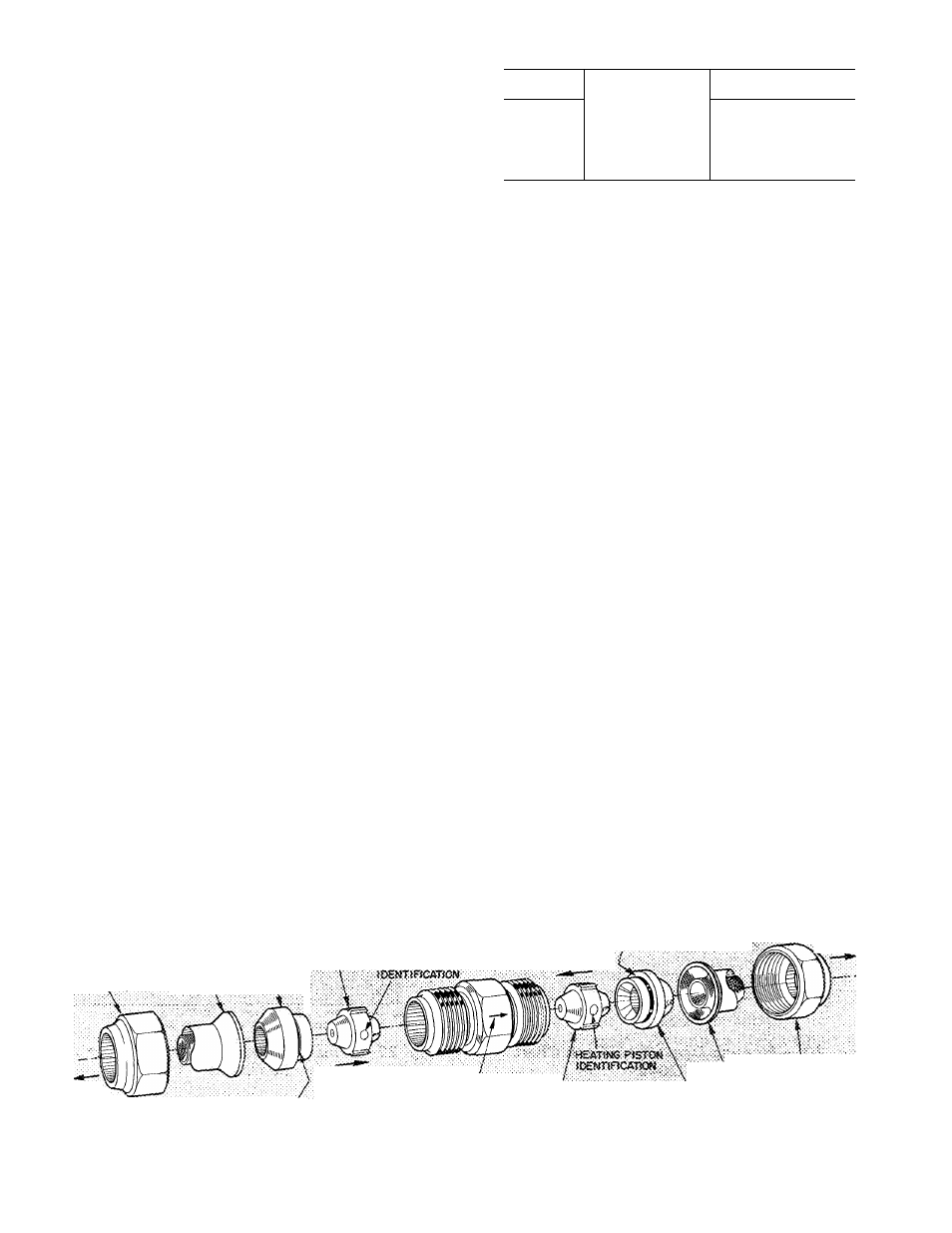

AccuRater™ (Dual-Piston Type) Servicing —

See Fig. 23 for dual-piston AccuRater components.

The pistons have a refrigerant metering orifice thru

them. The retainers form a stop for the pistons in the

refrigerant bypass mode, and a sealing surface for

liquid line flare connection. To check, clean or

replace piston;

1. Shut off power to unit.

2. Remove refrigerant from unit.

3.

Remove liquid line flare connections from

AccuRater.

4. Note position of arrow on AccuRater body with

respect to unit.

5. Pull retainer out of body. Be careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use vise grips to remove

retainer. Replace scratched or damaged retainer.

6. Slide piston out by inserting a small soft wire thru

metering hole (18-gage thermostat wire). See that

metering hole, sealing surface around piston

cones and fluted portion of piston are not

damaged.

7. Chart on unit access panel illustrates proper

arrangement and sizes of pistons.

8. Clean piston refrigerant metering orifice.

9. Replace container O-ring before reassembling

AccuRater.

Carrier

O-ring

part

no.

is

99CC501052.

LIQUID

LINE

STRAINERS

(protect

Accu

Rater), are made of wire mesh and located in the

liquid line on each side of the AccuRater. The

strainers are pressed into the line. Remove strainer

by threading a #10 sheet metal screw into strainer

and pulling the screw with pliers.

Compressor Removal

— See Table 5 for com

pressor information and Fig. 10 for component

location. Follow safety codes, and wear safety

glasses and work gloves. Have quenching cloth

available (step 8).

CAUTION:

ttibijag leased

ki

50 ¥Q

ccals. po xiot «yediest place excessive

Stiais iabxag

or

dasjage may result.

Table 5 — Compressor Data

MODEL

PRODUCTION

COMPRESSOR*

OIL RECHARGE (oz)

50YQ024

M24

44

50YQ030

M27

44

50Y0036

M34

44

50YQ042

P46

76

50Ya048

P53

76

50YQ060

P64

76

Refer to compressor nameplate for complete model number

1. Shut off power to unit. Remove unit access

panel. Fig. 10.

2. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service

Techniques

Manual,

Chapter

1,

Refrigerants.

3. Remove core from suction and discharge line

Schrader valves.

4. Disconnect compressor wiring at compressor

terminal box.

5. Using a tubing cutter, cut suction and discharge

lines at convenient place near compressor for

easy reassembly to new compressor with copper

clip couplings.

CAUTION: Excessive tiiovemesit of copper

Jities at compressor may cso&e a break where

Imes connect to other system componcius.

6. Remove crankcase heater from compressor

base.

7. Remove compressor hold-down bolts and lift

compressor out.

8. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

CAUTION: MoSkr may copiainquantity of

9.

10

.

Braze piping stubs (removed in step 8) on new

compressor.

Install new compressor in unit. Braze suction

and discharge lines to compressor piping stubs

(at points where cut, step 5) using field-supplied

copper couplings. Ensure compressor hold

down bolts are in place. Connect wiring.

fLARS

NUT

RETAiiÆR

S,TBA!Ï£B

-,

\

^

COOU^NS

PiSTON

COOUfiS PiSTON

HEATiwe

PLOW

RUЭДeЯO'Rl^4й

TO

■«DOOR

COOLfNS

P

low

RUeSERO-RlNG

STAii«PEDAf?i?OWOK

CCOPUING SOOr

(TCWAROiNDOOR COfU

PJSTO«

STRAiNER

RETAINER

PCARE

NUT

TO:

COTOOOR

cote

NOTE P«ton sizes are tabuteîed on unit access par.ef. Saainefs are îocateci >n iKjciti tine on eecti side ot AccuRater

Relative poS't'on of coccpor^er.ts is critical for ccrect operet.or.

Fig. 23 — AccuRater^^ (Dual-Piston) Components

1 2