Carrier 50YQ User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

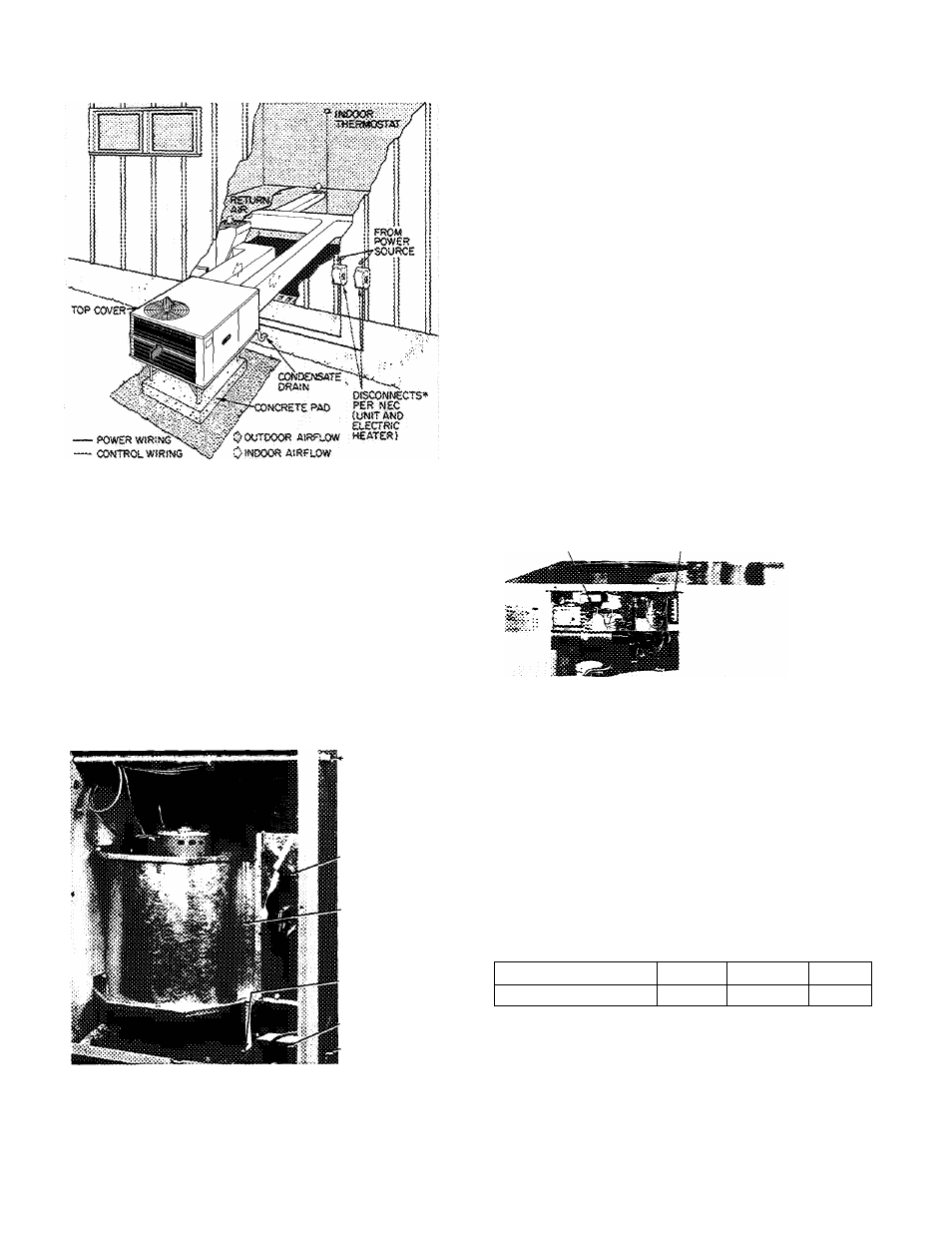

g. Secure all ducts to building structure. Weather

proof duct openings in wall or roof according to

good construction practices.

"Separate disconnect required for electric heater

> Fig. 4 — Typical Installation — 50YQ

Step 4 — Provide for Cooling Cycle Conden

sate Disposal

— Condensate may be drained

directly onto gravel apron or connected by drain

line(s) to a dry well. Follow local codes.

CONNECT DRAIN LINE to rubber condensate

drain fitting on side of unit (see Fig. 5). Use clamp

provided. Install factory-supplied condensate trap

(taped to indoor fan compartment for shipment) at

end of drain line. If a drain line is not used, connect

condensate trap to unit drain fitting as shown in

Fig. 5.

CONDENSATE

TRAP (SHIPPING

LOCATION, INSTALL

ON CONDENSATE

DRAIN LINE)

CONDENSATE

DRAIN LINE

¡i

DKO LINE

POWER

Fig. 5 — Condensate Drain and Trap Details

Step 5

—

Make Electrical Connections

— In

stall field wiring in compliance with local and

national fire, safety and electrical codes. Be sure

voltage to unit is within ± 10% of voltage indicated

on nameplate. On 3-phase units, check that phases

are balanced within 2%. Contact local power

company for correction of improper line voltage.

Oisrratton «kf tïiïÿi wth exijessm phase ¡as coiaM affect waCFaïïty, See Table 2 for recommended wire and fuse sizes. INSTALL A BRANCH CIRCUIT DISCONNECT PER NEC of adequate size to handle unit starting current. Provide a separate disconnect for unit required. (See electrie heater Installation, Start-Up and Service Instructions.) Locate disconnect(s) per Section 440-14 of National Electrical Code ROUTE LINE POWER LEADS INTO UNIT ^ provided (Fig. 1) into line wiring splice box (Fig. 6). Use copper or copper-clad aluminum wire. (Do not make connections with aluminum wire.) UNIT CONTROL WIRING TERMINAL BOX CONTROL WIRING Fig. 6 — Unit Control Box CONNECT GROUND LEAD TO GROUND LUG IN SPLICE BOX FOR SAFETY — Connect power wiring. See Fig. 7. Connect line power leads SET INDOOR FAN MOTOR SPEED — Refer to electric heater operation. Three-speed indoor fan Fan motor is equipped with spade-type speed selec tor terminals marked 1, 2 and 3. For electric heater operation, set motor at: “Low” — sizes 024 thru 042; MOTOR TERMINAL 1 2 3 FAN SPEED High Medium Low ROUTE CONTROL POWER WIRES (24-v) thru The 50YQ unit transformer supplies 24-v power for complete system including accessory electric 7 8 1

and for each accessory electric heater circuit as

within sight of and readily accessible from the unit,

(NEC).

Extend leads from disconnect per NEC thru hole

CONTROL BOX

CONDUIT,

to yellow and black pigtails on single-phase units;

yellow, blue and black pigtails on 3-phase units.

page 3 for minimum allowable air quantity for safe

motor is factory wired for high-speed operation.

“High” — size 048; “Med” — size 060.

7/8-in. conduit provided in unit. Fig. 1 and 5. Ex

tend leads to unit control wiring terminal board in

unit control box. Connect leads to terminal board

as directed in Fig. 8.

heater.