Service – Carrier 50YQ User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

If start thermistor is good and compressor does

not start, disconnect the thermistor from starting

circuit and give compressor a temporary capaci

tance boost as described below. Run compressor for

10 minutes, then shut off and allow system pressure

to equalize. Reconnect start thermistor and try

restarting compressor without boost capacitor. If

after 2 attempts the compressor does not start, re

move thermistor and add an accessory start capaci

tor relay package.

Single-Phase Units 50YQ024,030,036 and

042

— When supply voltage is within 10% limit

and compressor does not start, give compressor a

temporary capacitance boost.

^TEMPORARY CAPACITANCE BOOST — If

necessary, see Carrier Standard Service Techniques

Manual, Chapter 2, Electrical, for details.

WARKSNG; Cajjaciiaace boost Ls to be per-

fotaacfd írasaeá porsoKoeL improper

proce-

tlare cottjá «sose

injxtry.

SERVICE

High-Pressure Relief Valve

(Safety Control) is

located in compressor. Relief valve opens at a

pressure differential of approximately 550 psi

between suction (low side) and discharge (high side)

to allow pressure equalization.

Internal

Current

and

Temperature

Sensitive

Overload

(Safety Control) resets automatically

when internal compressor motor temperature drops

to a safe level (overloads may require up to 1 hour to

reset). When an internal overload is suspected of

being open, check by using an ohmmeter or con

tinuity tester. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 2, Electrical,

for complete instructions.

Defrost Control,

consisting of a defrost timer,

defrost thermostat and defrost relay, interrupts

normal system heating operation to remove frost

and ice formation on outdoor coil. Frost impairs

unit performance. Defrost control simultaneously

stops outdoor fan, energizes reversing valve sole

noid to switch system into cooling cycle (outdoor

unit as condenser, indoor unit as evaporator), and

activates accessory electric heater. Unit can defrost

every 90 minutes, but will do so only if outdoor tem

peratures are in the frosting temperature zone.

For heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature must be cold enough to

cause defrost thermostat contacts to close. Con

tacts close at 27 ± 3F.

Every 90 minutes of elapsed running time, the de

frost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit de

frosts. The defrost timer limits defrosting period to

10 minutes. Normally the frost is removed and the

defrost thermostat contacts will open to terminate

defrosting before 10 minutes have elapsed. Defrost

thermostat contacts open at 80 ( ± 6)F. When de

frosting is terminated, the outdoor fan motor is

energized and reversing valve solenoid is de

energized, returning unit to heating cycle.

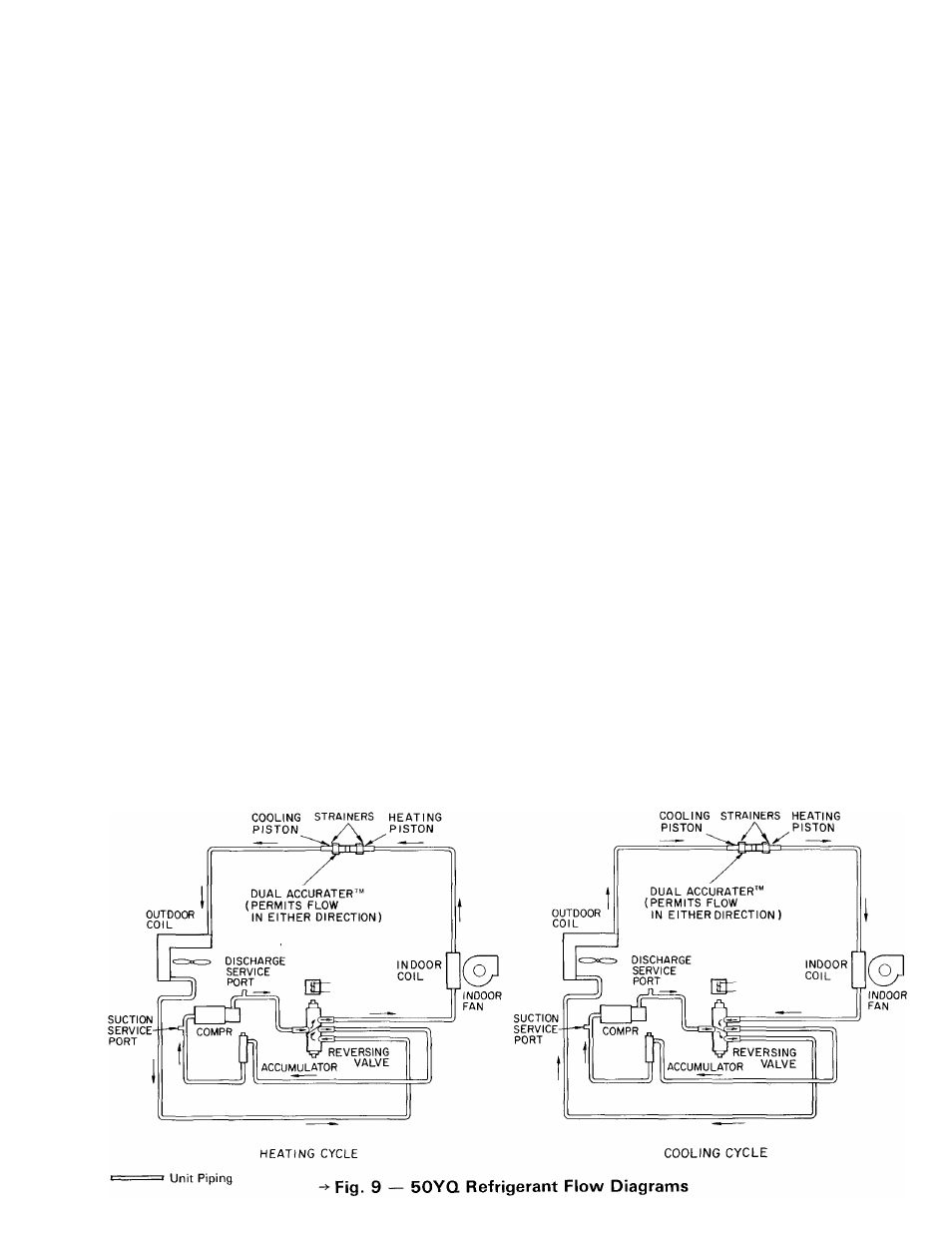

HEAT PUMP CIRCUITS shown in Fig. 9 are

refrigerant flow diagrams for heating and cooling

cycles.

> Refrigerant Charging

CAUTION: To

mcvem

personal injttxy, wear

safety

glasses

and

gloves

when

handHng

refrigerasL

Do not overcharge systemv An overcharge

can cause compressor flooding.

7 Q I