Control, Wt» access &msjs, Mnotutcpimz – Carrier 50YQ User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

■g CONDUIT

CONTROL-*“»

WIRING

0

'-6

j

3^

If DKO

ELECTRIC^

HEAT X

l| DKO

LINE

WIRING'

CONN

Fig. 1

L> INDOOR AIRFLOW

^ OUTDOOR AIRFLOW

RIGHT SIDE VIEW

Ceitified dimension drawings available on request

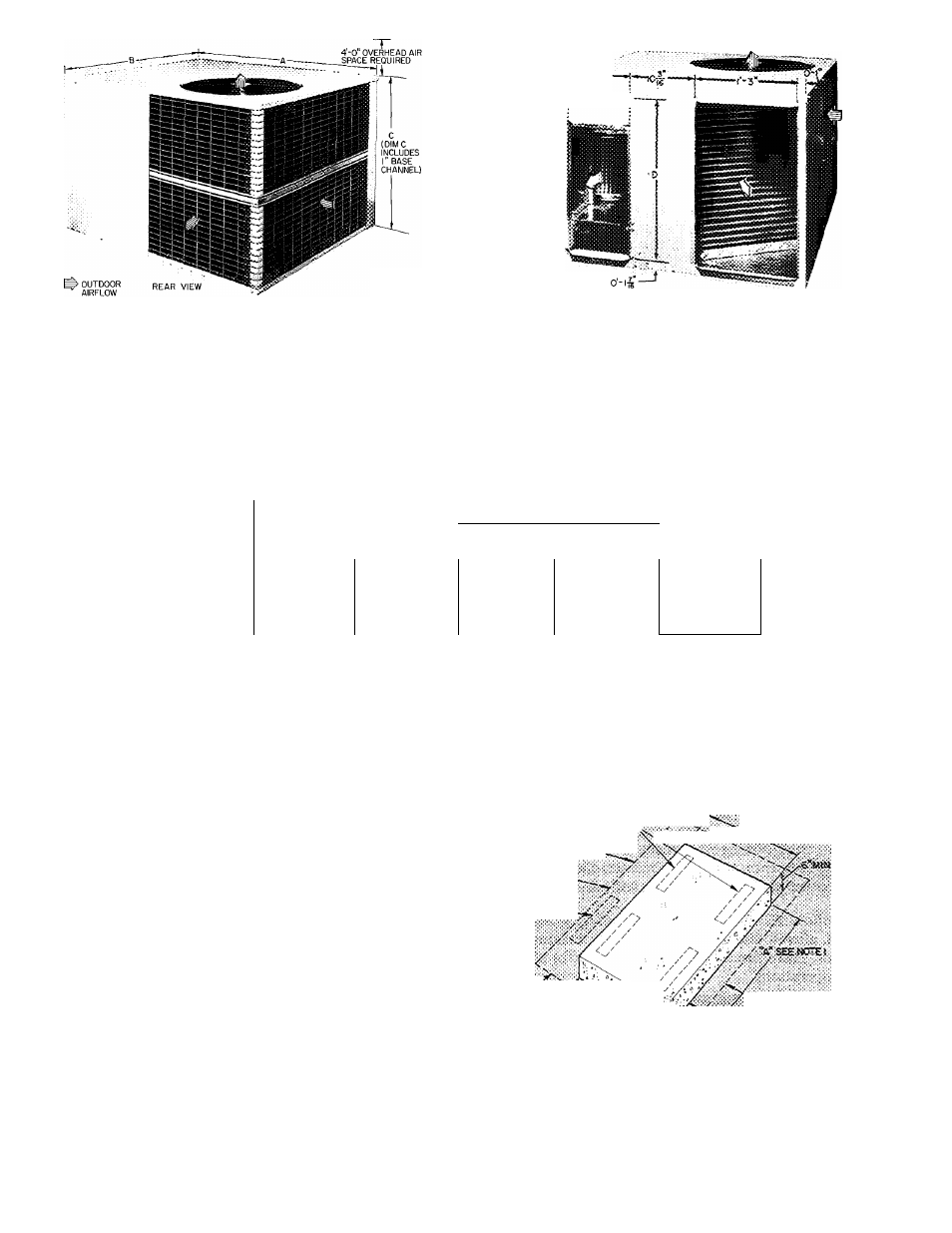

Dimensions and Connections

Table 1 — Installation Data (See Fig. 1)

UNIT

OPER WEIGHT (lb)

d

T

me

N

s

T

o

NS (ft-in )

A

B

50YQ024

303

50YQ030

320

50YQ036

333

50YQ042

375

50YQ048

417

50YQ060

4-0-7/16

3-6-1/4

C'

1-11-5/8

1-11-5/8

1-11-5/8

2- 3-5/8

2-7-5Z8

DUCT CONN (ft-in )

D

1- 7-3/4

1- 7-3/4

Side-by-Side Rectangular

1- 7-3/4 1 1-11-3/4

2-3-3/4

FILTER SIZEt (in.)

Disposable

20x25

15x20 (2)

15x20

20x20

20x20 (2)

20x25

20x20

Permanent

15x20

20x20

20x25

20x25

15x20 (2)

448

3-1-5/8

2-9-3/4

25x25

_2.Ûx25 ^

20x20 (2)

‘Dimension

"C"

includes

1-in

built-in

base

support

channels

fRecommended field-supplied filters are 1-in thick

Step 2 — Mount Heat Pump Package

ON THE GROUND; MOUNT HEAT PUMP ON

AN ELEVATED FRAME POSITIONED ON A

LEVEL CONCRETE PAD See Pig. 2 for pad

dimensions. Ensure pad does not obstruct coil slots

in unit basepan. (Slots drain water during heating

and defrost cycles. See Fig. 2 for drain slot loca

tions.) Construct pad a minimum of 6 in. thick to

provide clearance under basepan coil slots for

drainage and ice buildup. In areas where prolonged

subfreezing

temperatures

or

snowfall

occur,

increase clearance to 12 to 18 inches by constructing

an angle-iron frame to support unit 12 to 18 in. off

concrete base. Design cross angle of frame so as to

not obstruct basepan coil slots. See Fig. 3 for recom

mended frame construction. Alternate construction

should follow dimensions. Extend a 24-in. gravel

apron around pad for condensate and defrost water

drainage field.

ON THE ROOF: MOUNT UNIT ON A LEVEL

PLATFORM OR FRAME — Elevate unit for

proper clearance as described under ground installa

tion above. Design roof and plan water runoff so as

to prevent unit and its duct flashing from sitting in

water, in accordance with all applicable codes.

Step 3 — Make Ductwork Connections

CONNECT

RETURN

AND

SUPPLY

AIR

DUCTWORK — Connect ductwork to unit supply

and return air duct connections. Refer to Fig. 1 and

Table 1 for unit supply and return air connection

sizes and locations.

«Nfraasc

?ïEAfîsii«e8?a«(T^

UNIT OUTÏ-iN?-

•JEF^SSBE

NtWfTSaX:OFU1«T

«ïTH «JCT coitwecTfONS.

i

y-t ■

A / ■

fMm

WT» Access &msjs

ooKOT

i««oei%E»soss«E«T>

mnotutcPimz

^

d47«IS AilES.

mres.

t to 3f«as «lowiait «ievSKNf fr««» as(Xi, 3r«AS where eievsieci f:e«» is f.oi A w A2 iHmee&'cm B js 3T xiches 2 AJiow a 3'*t service, ctoarahce at frotrt fear anc feit sioe of unit Fig. 2 — Concrete Pad Dimensions