Carrier 30HK User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The electric heater is wired into the 115-volt

control circuit thru normally closed contacts of

control relay in such a way that it is energized only

when compressor is not operating.

All heaters are 125 watts.

C .\L 1 ION: Never open an\ >witeh or discon

nect that will de-encrgi/e crankcase healer un

less unit IS being serviced or will be shut down

tor a prolonged period. .Alter such service or

prrdonged shutdown, energize crankcase heater

lor 24 hours before starting compressor.

TIME GUARD® CONTROL

This control protects compressor against short

cycling (Switch A on four-function timer).

FOUR-FUNCTION TIMER

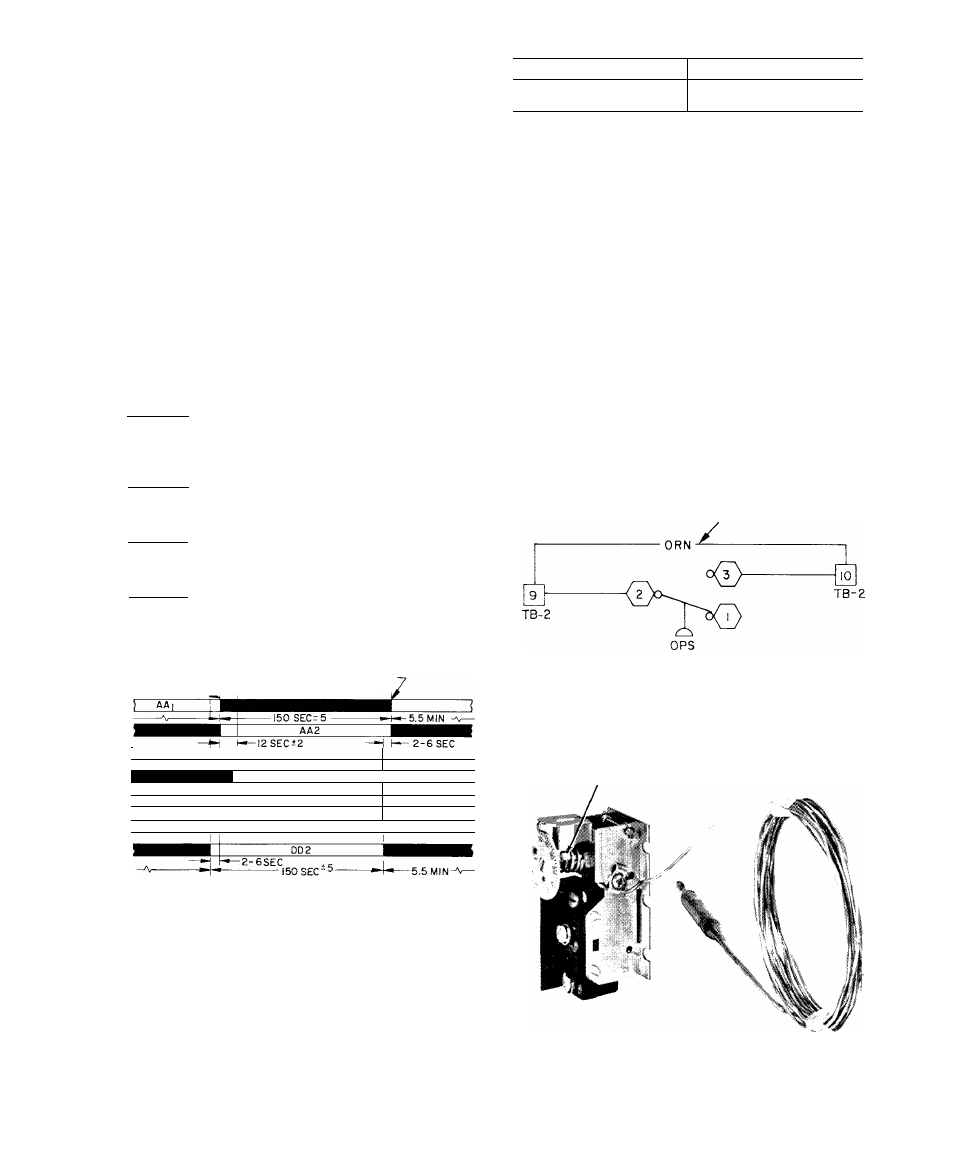

Refer to Fig. 4 — Timer Cycle. The functions are

as follows:

Switch A (Contacts A-Al, A-A2) runs timer motor.

This provides a minimum of 5-1/2 minutes after

compressor stops before it can restart, to prevent

short cycling (Time Guard control).

Switch B (Contacts B-Bl, B-B2) provides 1-second

time delay for part-winding start and also provides

a lock-out function.

Switch D (Contacts D-D 1) provides a 2-1 / 2 minute

bypass of the low-pressure switch at start-up to

prevent nuisance trips under cold-start conditions.

Switch E (Contacts E-El) provides a 35-second by

pass of the oil safety switch (OPS) at compressor

start-up (when OPS is used), if sufficient oil pressure

does not build up in this time, compressor stops.

0 OR 8 MiN.

POSITION DURING UNIT OPERATION-

COMPRESSOR STARTS

1 BBi

1 1

1--------------------------1

H 1—-1 SEC±05

H^SSECiZ

____ Щ_______ I . ............................................. 1

5

7 SEC±4 —И h

■«............^---------- 40SEC15

S DDI

NOTE: BLACK DENOTES CLOSED CONTACTS

Fig. 4 — Timer Cycle

OIL PRESSURE SAFETY SWITCH (OPS)

This control is standard on ЗОНЕ (condenserless)

units (020-030) and is available as an accessory for

30HK units (020-030). Refer to Fig. 5 for field

wiring connections. It is not available for the 015

unit.

The pressure switch is factory set at the following

pressures and should not be adjusted in the field.

SWITCH POSITION

PRESSURE SETTING

Close on rise

9 - 12 psi diff

Open on fall

4 - 6 psi diff

The oil pressure safety switch is wired in parallel

with Switch E of the 4-function timer. This arrange

ment allows approximately 35 seconds for oil pres

sure to reach normal operating level after com

pressor starts. If the oil safety switch does not close

within 35 seconds, the compressor shuts down.

To restart the compressor, the control circuit

ON-OFF switch must be pressed to OFF and then to

ON. The timer will start and after approximately

5-1/2 minutes compressor will start. If normal oil

pressure is established within the next 35 seconds,

the compressor continues to run. If, however, the oil

pressure does not reach a safe level, the compressor

stops at the end of the 35 seconds and locks out.

(’.ли I ION; Di' not attempt to restart the com

pressor tor a second time until the problem has

been determined and corrected.

REMOVE ORANGE Wl RE

OPS — Oil Pressure Safety Switch

TB — Terminal Board

Fig. 5 — Oil Pressure Safety Switch to

Control Box Wiring Connections

(020-030 Only)

LOW LIMIT STOP TAB

Fig. 6 — Safety Thermostat

(No. HH22CC050 Shown)

1090