Table 5 — electrical data; 3-phase, 60-hertz – Carrier 30HK User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

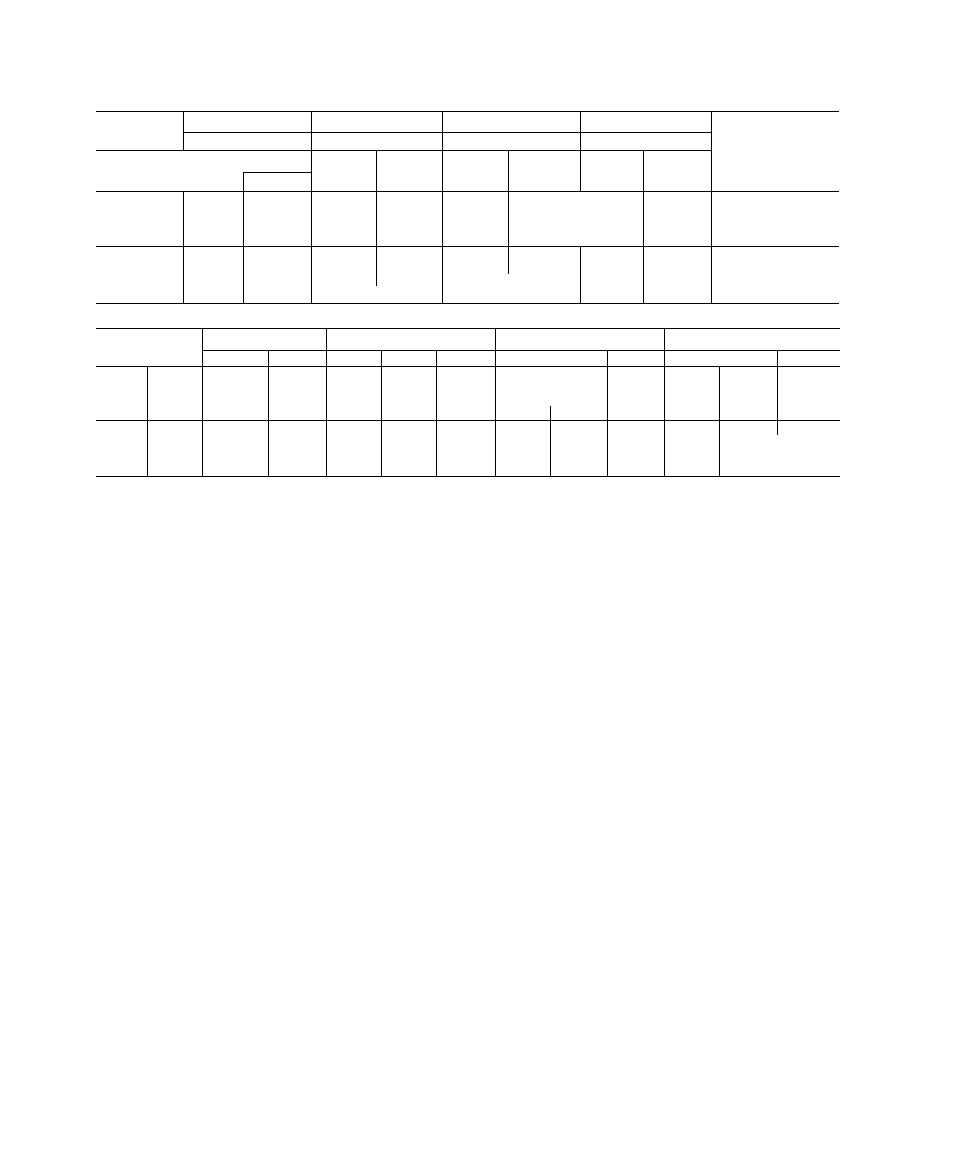

Table 5 — Electrical Data; 3-Phase, 60-Hertz

COMPLETE UNIT

VOLTS

Nameplate

208/230*

460

575

COMPRESSOR

06E USAGES

Supply Ränget

187-253

414-508

518 632

UNIT 30

MCA

Max

Fuse

Amps

MCA

Max

Fuse

Amps

MCA

Max

Fuse

Amps

MKW

015

16.4

69

110

34

60

29

50

0537**

020

21.8

79

125

36

60

34

60

2150

025

29.0

103

175

50

90

45

80

7265

030

31.0

115

200

50

90

49

80

7175

015

19.1

80

125

38

60

30

50

C537**

020

25.2

90

150

42

70

38

60

2250

025

31.8

115

200

50

90

45

80

7265

030

35.9

140

250

62

110

53

90

7275

INDIVIDUAL COMPRESSORS

COMPRESSOR

208/230V*

460 V

575 V

06t

Kw

RLA

LRA

MTA

RLA

LRA

MTA

RLA

LRA

MTA

015

0537**

16.4

55

266

77

27

120

37

23

96

31

HK

020

2150

21.8

63

283

88

29

142

40

27

98

37

025

7265

29.0

82

446

114

40

223

56

36

164

50

030

7175

31.0

92

446

128

40

223

56

39

164

54

015

0537**

19.1

64

266

89

30

120

41

24

96

33

HL

020

2250

25.2

72

345

100

33

173

45

30

120

42

025

7265

31.8

92

446

128

40

223

56

36

164

50

030

7275

35.9

112

506

156

49

253

68

42

176

58

KW — Maxi mum Power Input (compressor)

LRA — Locked Rotor Am.ps

MCA -- Mm imum Circuit Amps (for wire sizing). Complies with

National Electrical Code (NEC) Section 430-24.

MKW — Unit power input at operating conditions of 50 F Leaving

Chilled

Water

Temperature

(44

F

Saturated

Suction

Temperature) and 120F (FIK) or 145F (HL) Saturated

Discharge Temperature.

MTA — Must Trip Amps (factory-installed circuit breaker)

RLA — Rated Load Amps

’Compressors in ail models have extended voltage motor.

tUnits are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the range

limits shown.

fPrefix: 2 = 1 electric unloader; C, 7 = 2 electric unloaders.

”30FIK,HL015 models use 06D compressor instead

of 06E compressors.

START-UP AND SERVICE

WAk\lN(j; Shut oil all powur to unit hdorc

proceeding with any ^cr\!ce woik.

Initial Check

Do not attempt to start the liquid chiller even

momentarily until the following steps have been

completed.

1. Check all auxiliary components such as chilled

liquid circulating pump, cooling tower if used,

air handling equipment, or other equipment to

which chiller supplies liquid. Consult manu

facturer’s instructions.

2. Checksafety thermostat. See Safety Thermostat.

3. Determine if there is a refrigerant charge in the

system. Refer to Check Refrigerant Charge.

4. Backseat (open) compressor suction and dis

charge shutoff valves.

5. Open liquid line shutoff valves.

6. Open valves to capillaries of water-regulating

valve (when used).

7. Fill chilled liquid circuit with clean water or

other noncorrosive fluid to be cooled. Bleed

all air out of high points of system.

8. Open supply valve (or fill cooling tower if used)

for condenser cooling water.

9. Set temperature controller.

Check tightness of all electrical connections.

Be sure compressor is floating freely on the

isolation springs. See installation. Step 3.

Check compressor oil (should be visible in

bull’s-eye). Refer to Check Oil Charge.

Be sure crankcase of each compressor is warm

(heaters should be on for 24 hours before start

ing compressors).

Check Refrigerant Charge

IMPORI AN'l; Do not open liquid \al\e or

compressor discharge \al\e until there is a

charge in remainder ol system. .A positive pres

sure will indicate a eharue in svstem.

10

.

11.

12

.

13.

1090