Carrier 30HK User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Tube information:

in.

(mm)

Tube sheet hole diameter...... .... 0.631

(16.03)

Tube OD............................... .... 0.625

(15.87)

Tube ID after rolling............. .... 0.581

(14.76 to

(includes expansion due

to

14.94)

to clearance)

0.588

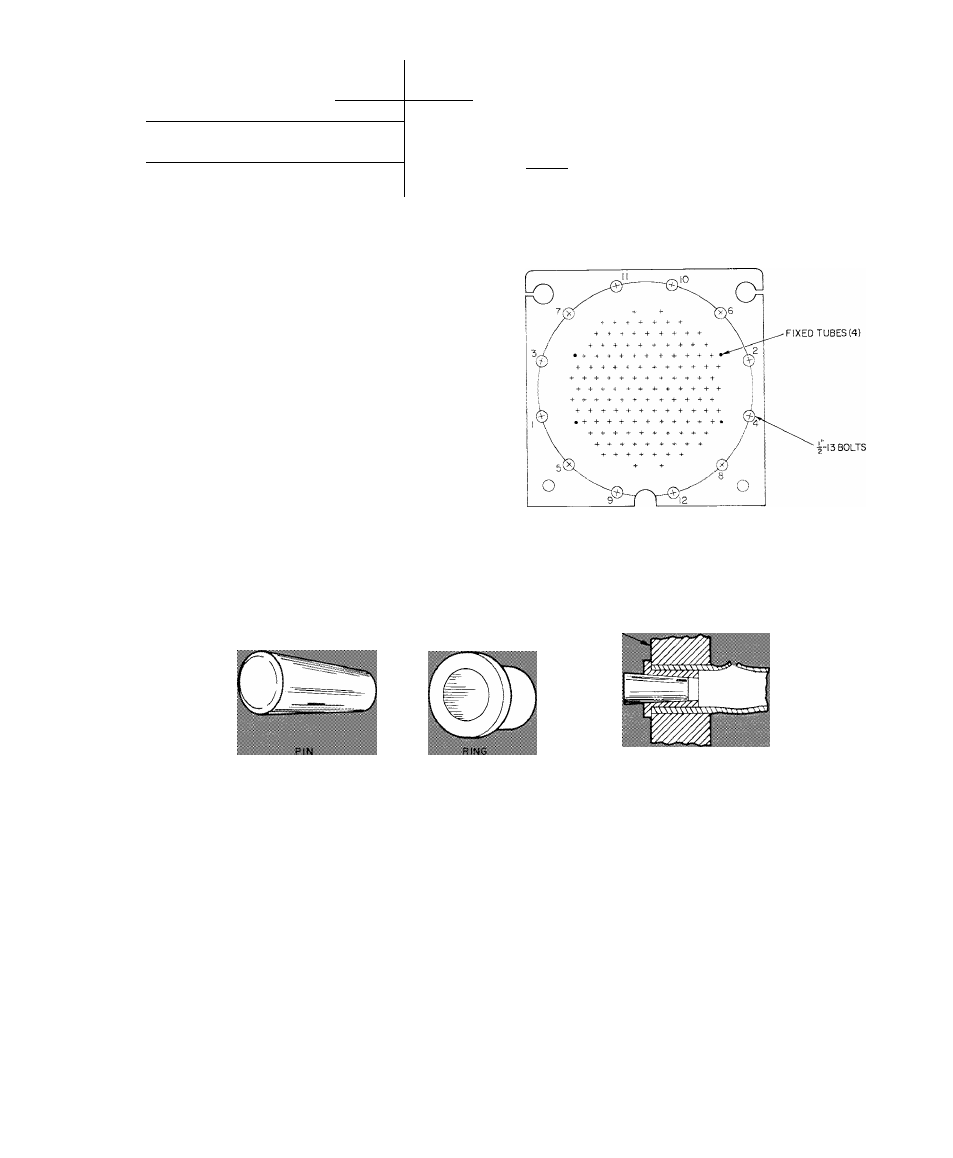

BOLT TIGHTENING SEQUENCE (Fig. 11)

The following is a recommended bolt tightening

sequence:

Step 1 — Tighten moderately (without torquing)

all the flange bolts in sequence shown.

Step 2 — Repeat Step 1, tightening bolts to speci

fied torque.

NOTE: Tubes next to gasket webs must be flush

with tube sheet (both ends).

Tightening Cooler Head Bolts

GASKET PREPARATION

When reassembling, use new gaskets. Com

pressed asbestos neoprene gaskets. Carrier Material

Specification ZAOO-24, are to be momentarily

dipped in compressor break-in oil prior to assembly.

Do nut soak gaskets in oil as gasket deterioration

results. Use dipped gaskets within 30 minutes to

prevent deterioration.

BOLT TORQUES

Apply the following torques during bolt tighten

ing sequence described below:

1/2-in. diameter flange bolts.............. 70 - 90 lb ft

Fig. 11 — Tightening Sequence,

Cooler Head Bolts

Tuet SHEET

Fig. 10 — Elliott Tube Plug

13

1090