Carrier 30HK User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

6. ANY SAFETY DEVICE TRIPS.

If device is low-pressure switch, reset is automatic

and unit restart is thru normal timer cycle. In the

case of low, or lost, refrigerant charge, charge

must be increased to normal level before restart.

If device is one of the following, high-pressure

switch, overtemperature switch or oil pressure

safety switch, press control circuit ON-OFF

switch to OFF, then to ON. Restart occurs thru

normal timer cycle.

If chilled water flow has stopped, locate and

correct cause, restart water flow. Unit will restart

automatically thru normal timer cycle.

IMi’Oxl .ANl; И sU;ppage b\ ;; •.aic;;. deuce

rcpca.s -..nee. do attempt am/ti'cr restart

unt..

IS ds

titted and cotijcted

Refer also to Troubleshooting section for addi

tional information on unit malfunctions.

Tube Plugging

— Leaky tube(s) can be plugged

until retubing can be done. The number of plugged

tubes determines how soon cooler must be retubed.

If several tubes require plugging, check with your

local Carrier representative to find out how number

and location will affect unit capacity.

Figure 10 shows an Elliott tube plug and a cross-

sectional view of a plug in place. Table 8 lists the

components for plugging.

C.Ai'ilON; Use e.vtreme caie when mslalling

plugs to prevent damaging the lube sheet sec

tions between holes.

Clean parts with Loequie "N" and apply a few

drops of Loctite #75 to obtain a tight seal without

using too much force to set pin.

Usually plugs can be removed by heating pro

jecting end of pin to approximately 1000 F and

chilling quickly with water. Apply heating flame to

side of the pin to prevent overheating tube sheet.

c

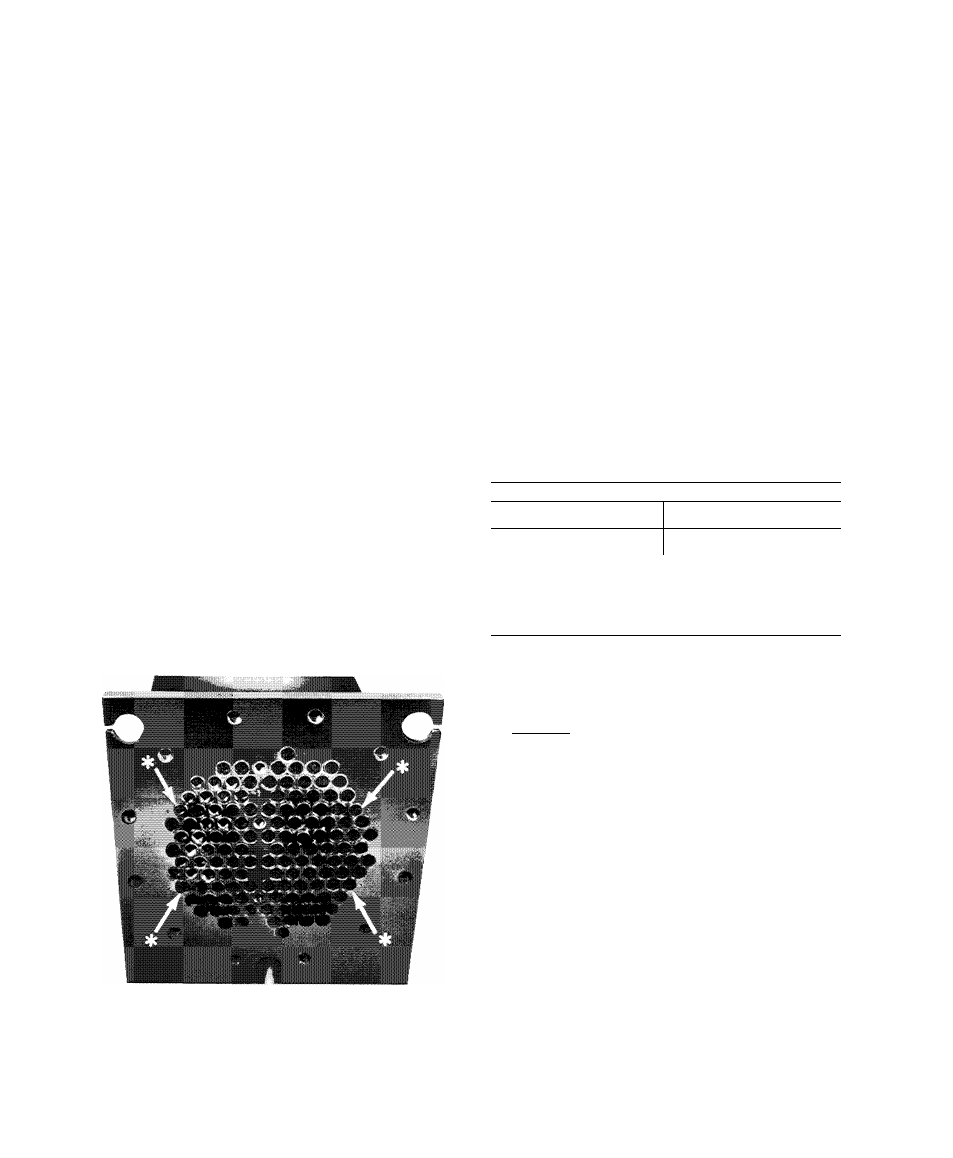

SERVICING COOLER

When cooler heads and partition plates are

removed, tube sheets are exposed showing tube

ends shown in Fig. 9.

C.-M I'lON; Four lubes m the bun-.iie .ue 'Ci,tired

inside cooler at baffles and cannot he removed.

These are identified on the tube sheets by a drill

mark horizontally adjacent to each of the 4

lubes.

!; iruku^te

o; ^

oi ou\

- V

4 m!>< s.

Jc.M r:;>eJ i:ihler Inhe

Table 8 — Plugs and Tubes

‘Four fixed tubes (cannot be removed) identified by adjacent drill

points.

Fig. 9 — Typical Tube Sheet

UNIT 30HK.HL j

015.020 025,030

COMPONENTS FOR i

PLUGGING i

PART NUMBER

For Tubes i

Brass Pin

853103-500‘

Brass Ring

For Holes without Tubes |

853002-570*

Brass Pin '

853103-1*

Brass Ring i

853002 631 '

Loctite i

No. 75t

Loequie i

-N"t

‘Order directly from Elliott Tube Co.

Dayton, Ohio.

tCan be obtained locally.

Retubing (See Table 8) — When retubing is to be

done, obtain service of qualified personnel exper

ienced in boiler maintenance and repair. Most

standard procedures can be followed when retubing

the lOHA coolers. A (i% crush is recommended

when rolling replacement tubes into the tube sheet.

A 6% crush can be achieved by setting the torque on

the gun at 48 to 50 in. lbs.

The following Elliott Co. tube rolling tools are

required:

В3400 Expander Assembly

B3401 Cage

В 3405 Mandrel

B3408 Rolls

Place one drop of Loctite No. 67541, or

equivalent, on top of tube prior to rolling.

1090

12