General operating sequences, Service, Turn thermostat selector switch to “off – Carrier 48DH User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL OPERATING SEQUENCES

These sequences apply to both natural and LP

gas units in normal operation after initial start-up.

Operating Sequence — Heating

1. Pilot ignited. Thermostat selector switch at

“Heat” or “Auto.” Thermostat dial set above

room temperature.

2. Main gas valve circuit is energized. Gas valve on

LP units opens immediately; gas valve on

natural gas units opens in 10 — 15 seconds.

3. TDR starts indoor fan in 30 — 45 seconds.

4. When thermostat setting is satisfied, main gas

circuit de-energizes. LP gas valve closes imme

diately; natural gas valve closes in 1 0 — 1 5

seconds. Gas flow to main burners stops and

flame is extinguished.

5. TDR stops indoor fan 1.0 — 1.5 minutes after

thermostat setting is satisfied.

6. Limit switch shuts off gas valve if air circulation

is restricted, but fan continues to run. Pilot

automatically reignites if extinguished.

Operating Sequence — Cooling

1. Unit energized. Thermostat selector switch at

“Cool” or “Auto.” Thermostat dial set below

room temperature.

2. Indoor and outdoor fans and compressor start.

3. When thermostat setting is satisfied, fans and

compressor stop.

Automatic Operation

— Power and gas on. Room

thermostat (control center) set at “Auto.” Fan

switch (on control center) set at “Auto.”

Unit performs as described in the operating

sequences above on call for heating or cooling.

Automatic changeover type thermostat is required.

Continuous Fan Operation

— With power supplied

to unit and fan switch at “On” position, indoor fan

remains on at all times.

Size 002 units require a field-installed accessory

indoor fan relay with N.O. contacts in parallel with

TDR contacts for continuous fan operation.

Complete Shutdown or Change from Heating to

Cooling

1. Turn thermostat selector switch to “Off.”

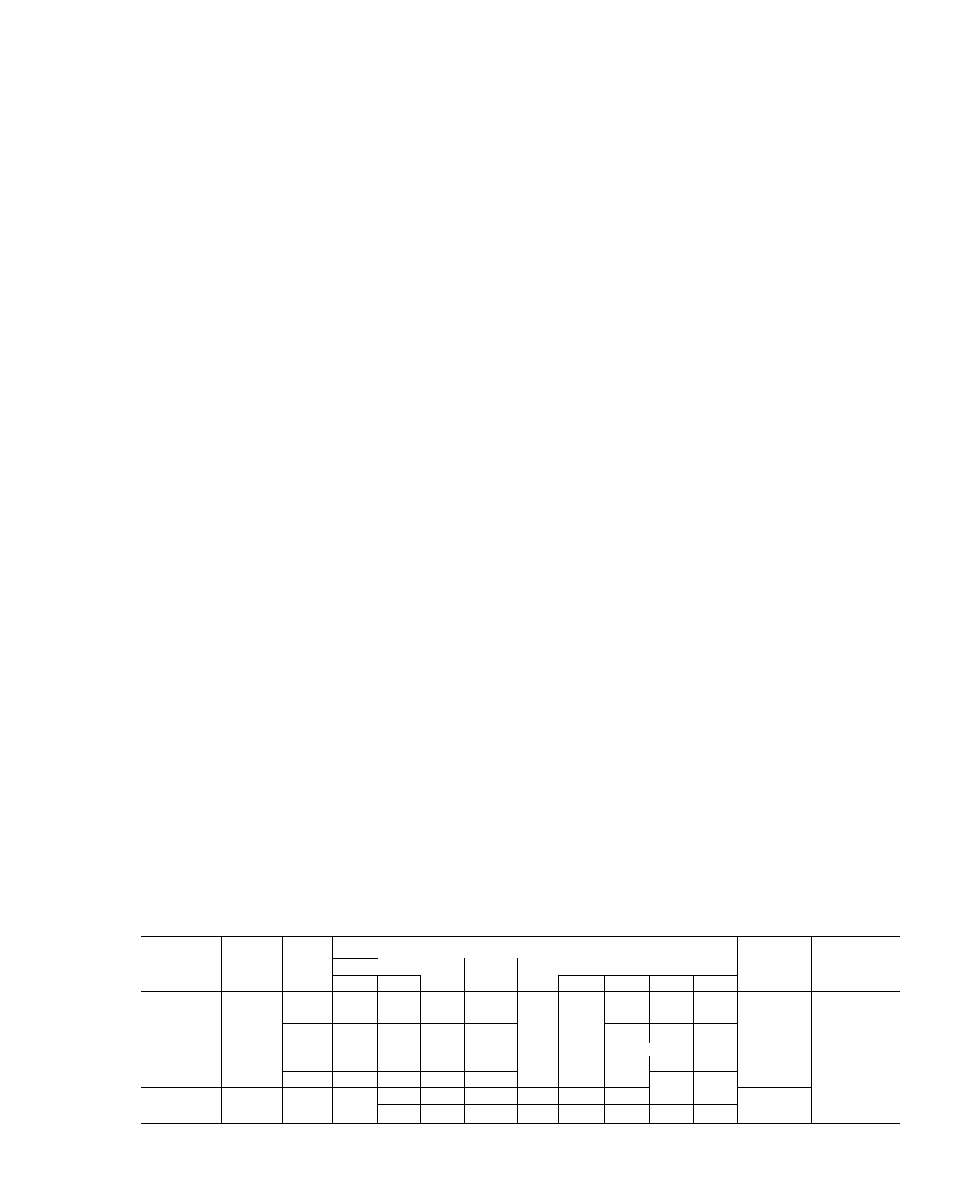

Table 5 — Manifold

2. Remove heating section access panel.

3. Turn manual shutoff valve (Fig. 8) to “Pilot.”

Then depress valve and turn to “Off.”

4. Turn off power. Replace access panel.

SERVICE

Adjusting Main Burner Gas Input

(Refer to Fig. 4 and 8 and to Table 5 and 6) —

Need for adjustment is determined by comparing

measured gas input (flow rate or manifold

pressure) against the rated input of a gas with a

specific heating value. Check local gas supplier for

correct heating value (BTU’s per cu ft). Before

measuring, shut down all other gas appliances.

Flow rate (cfm), the most accurate method, is

measured by gas meter and stop watch. Check

measured flow against rated flow in Table 6.

Manifold pressure (in. wg) is measured as

follows:

1. Remove heating section access panel.

2. Shut down unit and close gas supply line valve

(Fig. 4).

3. Remove pressure tap plug from main gas valve

(Fig. 8) and install pressure tap.

4. Attach U-tube water gage manometer to

pressure tap and open gas supply line valve.

5. Start up heating system.

6. Measure gas pressure (in. wg) and compare with

rated pressure in Table 5.

To adjust pressure or flow rate:

1. Remove pressure regulator adjusting screw cap

on main gas valve (Fig. 8).

2. Turn screw slowly, clockwise to increase pres

sure (flow), and counterclockwise to decrease.

3. Replace adjusting screw cap.

4. Shut down heating system.

5. Close gas supply line valve, remove manometer

and replace pressure tap plug.

6. Open gas supply line valve and replace heating

section access panel.

Pressure {in. wg)

TYPE

BTU

SP

GR

UNIT

MAIN

PILOT

ORIFICE

OF

PER

48DH

48DM

48DL

BURNER

GAS

CU FT

002

004

005

004

002

003

004

045

005

ORIFICE

1000

,60

3.3

3,0

3.0

3,4

3.5

3.3

3.3

3.0

3.4

65

3.5

3.2

3.2

3.6

3 7

3 5

3.5

3.2

3.6

Natu ra!

1050

.60

3.0

2.7

2.7

3.1

3.2

3.0

3.0

2.7

3,1 J

#41

016 in

Drill

65

3.2

2.9

2.9

3,3

3.4

3 2

3.2

2.9

3.3 1

1100

.60

2.7

2.4

2.4

2.8

2.9

2.7

2.7

2.4

2.8

.65

2.9

2.6

2.6

3.0

3.1

2.9

2.9

2.6

3.0

Butane

3200

2

00

11 5

10 5

10 5

12

2

12

0

11 5

11.5

10 5

12

2

#54

010

in

Propone

2500

1.53

12

2

11

2

11

2

12 9

13 0

)2

2

12

2

11

2

12 9

Drill

SP GR

— Specific Gravity