Fig. 8 — unit gas valves – Carrier 48DH User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Example: measured resistance .32 ohm x 2 - .64

.64 divided by 0.032 = 20

Cut off 20 in. of resistance wire.

CHECK MAIN BURNERS

1. Check automatic pilot as previously described.

2. Measure and adjust main burner gas input as

described in Service section.

3. Turn main gas valve to “On” position and

operate unit for at least 15 minutes with all

access panels in place.

4. Remove heating section access panel.

5. Turn each primary air adjustment screw (Fig. 7)

clockwise until yellow tips appear on burner

flames. Then turn each screw counterclockwise

(about 3/4 turn) until flames become clear,

almost transparent blue with a well defined

inner cone. If the flames lift off the burner

ports, turn the screw clockwise slightly.

BURNER ADJUSTMENT SCREW

FINAL HEATING SYSTEM CHECKOUT - Move

thermostat dial above and below room temperature

setting several times, pausing at least 5 minutes

between cycles. Check pilot flame, main burner

ignition, flame characteristics and indoor (evap

orator) fan motor time delay relay operation.

Replace heating section access panel.

COOLING SYSTEM CHECKOUT

1

.

2

.

3.

Turn power on.

Set room thermostat selector switch at “Cool”

or “Auto.” and dial setting below room

temperature.

Move thermostat dial above and below room

temperature several times, pausing at least 5

minutes between cycles. Check fan and com

pressor operation. If compressor fails to start,

refer to the following section entitled Check

Compressor Start.

Check unit operating voltage. Voltage must be

within ±10% of nameplate voltage.

Check cooling effect at air outlets.

Check that field-supplied filter is in place.

Check action of safety devices and controls.

Check Compressor Start

— Single phase compres

sors of split capacitor (PSC) type require equalized

system pressure to start. When supply voltage is

within ±10% of nameplate voltage and the compres

sor fails to start, give the compressor a temporary

capacitance boost.

Use a start capacitor, sized as listed below, with

a bleed resistor wired across the terminals.

4.

5.

6

.

7.

Fig. 7 — Main Burner Adjustment

UNIT SIZE

CAPACITOR RATING

002 thru 004

045 thru 005

108

135 -

130 mfd, 370 V

155 mfd, 370 V

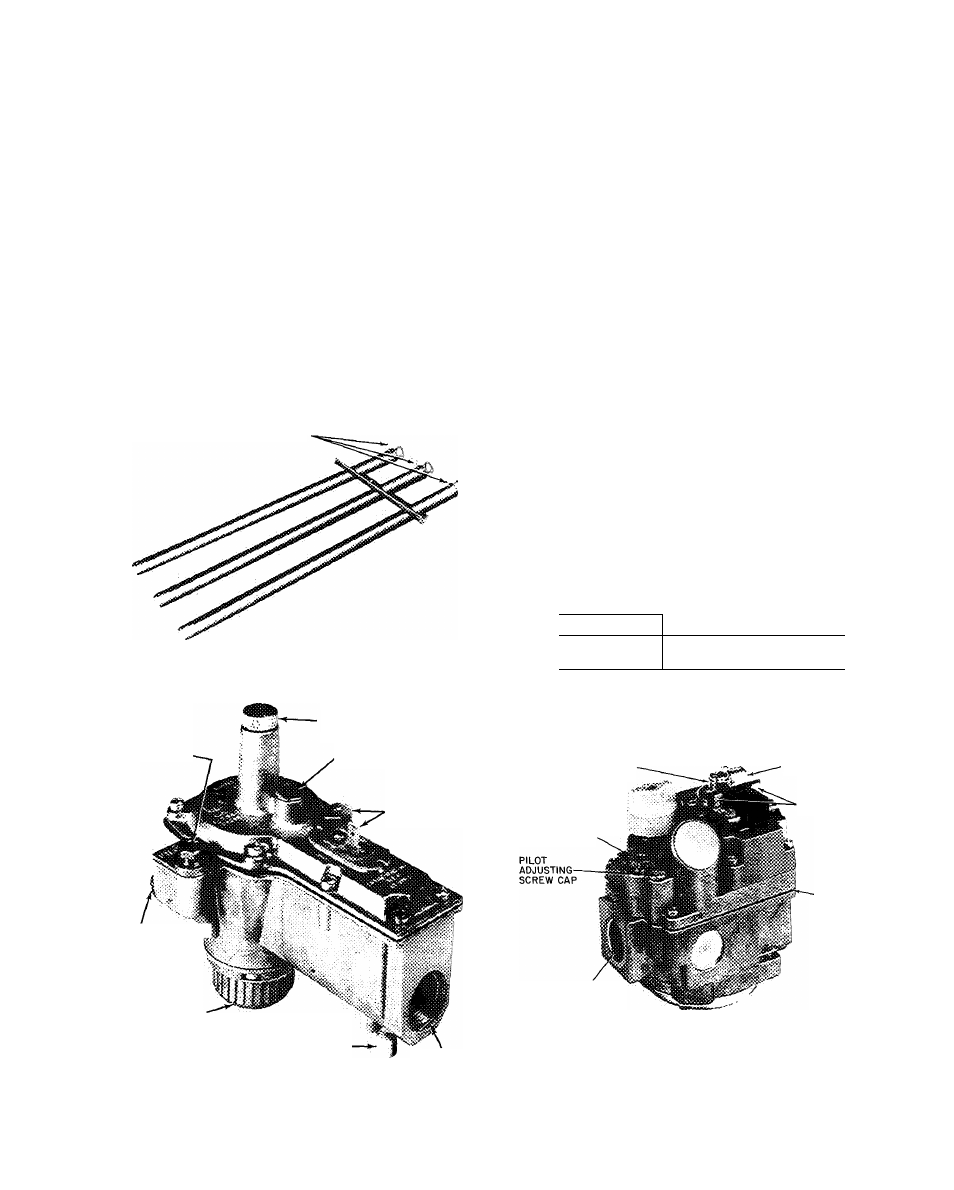

PILOT GAS LINE

CONNECTION

REGULATOR

ADJUSTING SCREW CAP

REGULATOR VENT

AND DUST CAP

LOW-VOLTAGE

CONNECTIONS

PILOT ADJUSTING 'i?

SCREW CAP

MANUAL SHUTOFF

VALVE AND PILOT COCK

NATURAL GAS VALVE

PIPE PLUG FOR

PRESSURE TAP

VALVE

OUTLET

REGULATOR ADJUSTING

SCREW CAP

MANUAL SHUTOFF

VALVE AND-----------

PILOT COCK

PILOT GAS LINE

CONNECTION

REGULATOR VENT

LOW VOLTAGE

CONNECTIONS

PRESSURE

TAP

(HIDDEN)

MAIN GAS LINE

CONNECTION

LP GAS VALVE

Fig. 8 — Unit Gas Valves