Carrier 48DH User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

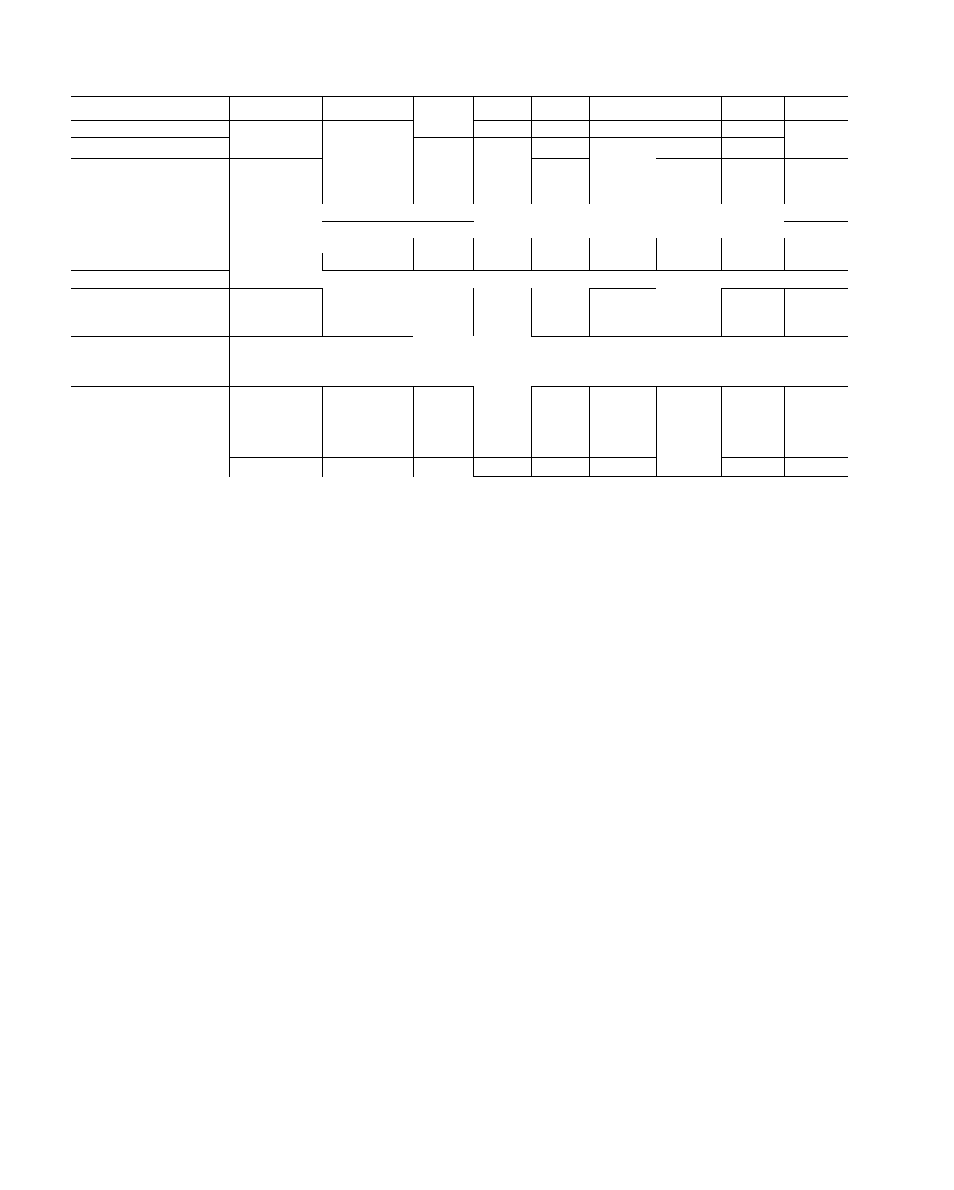

Table 2 — Physical Data

UNIT

48DL002

48DH002

48DL003

48DL004

48 DM004

48DH004

48DL045

48DL005

48DH005

OPERATING WT (lb)

331

343

385

411

430

438

450

476

512

REFRIG (22) CHG (Ib-oz)

3.2

3 2

3.6

5 1

5 1

5 2

5 1

5 1

COMPRESSOR

M27 (1-ph)

M27 (1-ph)

M34

M40

M40

M40

P46

P53

P53

AHbbz^/h(J-ph)

AH5527h(3-ph)

Cyl inders

2

2

2

2

2

2

2

2

2

Rpm (60-Hz)

3500

CONDENSER FAN

Propel ler-Typ e — Direct Drive; Vertical Disc

large

Air Quantity (Cfm)

1700

1700

2000

2500

2500

2500

2700

2700

2700

Motor Hp

Vs

Vs

Vs

Vs

Vs

Vs

Vs

V,

Vs

EVAPORATOR FAN

Centrifugal — Direct Drive; Horizontal Discharge

CAPACITY (1000 Btuh)

Г

Cool in g

24

24

30

36

36

36

42

48

48

Input Heotlng/Bonnet*

56/42

80/60

80/60

80/60

110/82 5

125/93 75

100/75

110/82 5

150/112 5

MAX EXTERNAL

STATIC PRESSURE

Heating (in. W.C.)

40

FILTERSt (1-in. thick)

Disposable — No. ..

1 15x20

1 15x20

1 15x20

1 20x25

1 20x25

Size (in.)

1 .20x25

1 20x25

2 15x20

1 20x20

1 20x20

1 .20x20

2 20x20

1 25x25

1 .25x25

Permanenti — No. ..

Size (in.)

1 15x20

1 15x20

1 20x20

1 20x20

1 20x20

1 .20x20

1 20x25

2 15x20

2 15x20

HEAT TEMP RISE (F)

35-65

45-75

35-65

35-65

35-65

45-75

35-65

35 65

45-75

* Ratings shown for elevations up to 2000 ft above sea level. For ele

vations above 2000 ft deduct 4% capacity for each 1000 ft above

sea level

i Recommended field-supplied filter

ifBased on 0.082 in. wg pressure drop or less thru filter at 520 ft/min

face velocity.

OUTSIDE AIR LIMITATIONS - Although there

are no restrictions on either the percentage or the

temperature of the outside air circulated thru the

unit, the rate of moisture condensation from the

combustion process increases significantly when

return air temperature drops below 50 F. Protect

the drain holes in the bottom pan against ice

buildup if outside air of below freezing tempera

ture is used

VIBRATION ISOLATION -- The unit compressor,

evaporator fan and condenser fan are mounted on

isolators to minimize vibration. Additional isola

tion is not required for slab mounting. With some

types of roof construction, however, the use of

field-furnished mbber pad type isolators may be

advisable.

Unit Rigging

1. Sling the unit perpendicularly to shipping skid

mnners. Use spreader bars to prevent damage

from sling or cable.

2.

Raise unit to desired location and remove

shipping skid.

3. Mount and level the unit as indicated in Unit

Support and Mounting section.

Unit Support and Mounting

LEVELING THE UNIT — Level the unit from end

to end but pitch the unit slightly (3/8 to 1/2 in )

towards the condensate drain on the service access

face of the unit (Fig. 1). Use the unit frame as a

leveling reference.

SLAB MOUNTING — Mount the unit on a

concrete pad, cement blocks, bricks or creosoted

wood of sufficient area and strength to support the

unit weight (Table 2) without distortion or damage

and maintain the drainage pitch recommended

above.

A gravel apron will prevent grass and foliage

from obstructing the condenser air inlet (Fig. 1).

FLAT OR RECESSED ROOF MOUNTING should

be as close as possible to the roof duct opening

Place the unit on at least 2 wooden 2x4 in. or

2x6 in. sleepers.

Sleepers may be perpendicular to or parallel to

the unit mounting rails, but must span at least 2

roof joists or purlins to distribute unit weight. Set

the sleepers in roof cement or mastic. Do not plug

drain

holes

in

the

compressor

or

furnace

compartment.

Do not support the unit by the ends of the base

rails, nor use vibration isolators at these points.

Unit will not be properly supported and could sag

in the middle.

PITCHED ROOF MOUNTING -- Constmct a

s t u r d y

w e l d e d

o r

b o l t e d

f r a m e o f

1-1/2

X

1-1/2

X

1/4 in. or larger angle iron, with

frame members at right angles to unit rails. Make

provisions for securing unit to frame. Use roof

cement or mastic where frame is in contact with

roof.

%