Never use an open ñame for leak testing, 208/l – Carrier 48DH User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

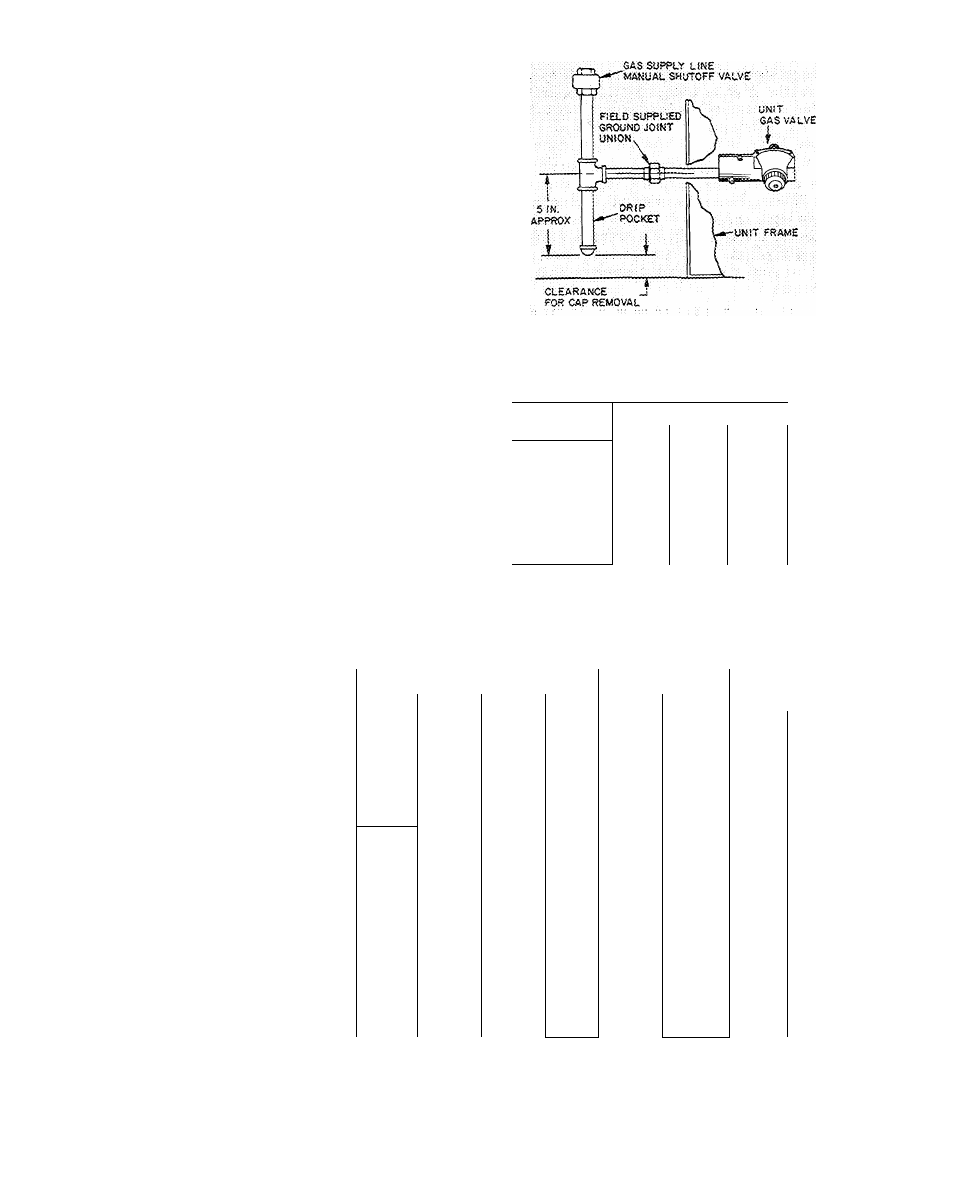

1. Furnish the gas line from the main gas supply

to the unit gas valve (Fig. 4).

2. Size the supply pipe for 0.3-in. wg maximum

pressure drop and for the volume of gas

required (Tables 3, 5 and 6). Pipe size must

equal or exceed size of gas connection at unit.

3. Use pipe dope approved for use with liquefied

petroleum (LP) gases.

4. Pitch all horizontal pipe runs towards the unit

1/4 in. per 15 ft to prevent trapping condensed

moisture.

5.

Support piping to maintain proper pitch,

prevent strain on unit controls, and prevent

accidental movement of piping.

6. Install a tee for attachment of a dirt and

moisture drip pocket (Fig. 4). Tee should be at

same level or below gas valve connection. Drip

pocket must be protected against freeze-up.

7. Install manual shutoff valve on gas piping per

local codes.

8. Provide a ground joint union in the gas supply

line near the unit gas valve.

9. Protect gas piping from freezing temperatures.

Gas stoppage can result from failure to insulate

pipe against wide or sudden temperature

changes.

10. When piping is completed, check entire gas

assembly and field piping with soap and water

solution.

Never use an open ñame for leak testing.

Fig. 4 — Gas Piping Details

Table 3 — Maximum Pipe Cap. (cfh)^

PIPE

NOMINAL PIPE SIZE

LENGTH (ft)

V.

V

/ 4

1

10

132

278

520

20

92

190

350

30

73

152

285

40

63

130

245

50

56

115

215

60

—

105

195

70

96

180

80

_

90

170

90

—

84

160

100

-

79

150

1

V

4

1050

730

590

500

440

400

370

350

320

305

*Cfh — Cu ft/hr based on 0.3 in. wg pressure drop and 0.6 gas

specific gravity.

NOTE;

Correction is not necessary for normal number of fittings nor

for 0.7 gas specific gravity unless specified.

Table 4 — Electrical Data (60-Hz)

UNIT

Model

Serie

48DL,DH

002

48DL

003

48DL,DH,

DM004

48DL

045

48DL,DH

005

200

300

400

200

300

400

500

^00

300

400

500

600

200

300

400

500

600^

200

300

400

500

600

VOLTAGE

Norn V/Ph

230/1

208/3

208/1

230/1

208/3

230/3

___ 460A3__

'^208/l~

230/1

208/3

230/3

460/3

208/1

230/1

208/3

230/3

460/3

'208/1^

230/1

208/3

230/3

460/3

UNIT

COMPR

OFM

WSA

FLA

ICF

FU

FLA

LRA

FLA

23 5

19 5

83 4

35

16 1

80 0

2 0

1 4

21 6

17 9

75 4

30

14 5

72 0

2 0

1 4

16 8

14 0

58 4

20

10 6

55 0

2 0

1.4

29 8

24 3

102.8

40

20.8

99 0

2 4

1 4

27 3

22.3

91 8

35

18.8

88.0

2 4

1 4

18.8

15 5

73 8

25

12 0

70 0

2 4

1 4

17 4

14 4

63.8

25

10 9

60.0

2 4

1.4

8.8

7 4

31 9

15

5 5

30 0

2.4

1 4

39 0

32 4

117 9

50

26 5

112,0

3 1 1

2.8

35 9

29 9

105 9

45

24 0

100 0

3 1

2.8

25 0

21 2

85 9

30

15 3

80 0

3 1

2 8

23 3

19 8

75 9

20

13 9

70 0

3.1

2 8

11.3

10.0

39.0

15

7 0

35 0

3 1

2.8

41 0

34 1

115 6

60

27 5

109 0

3 8

2.8

36 5

30 5

100 6

50

23 9

94 0

3 8

2 8

27.4

23 2

85.6

35

16 6

79 0

3 8

2 8

24 5

20 9

73 6

30

14 3

67 0

3 8

2.8

12 4

10 6

38 3

15

7 3

35 0

3 8

2 8

46 5

38 5

132.6

60

31 9

126 0

3 8

2.8

41 5

34 5

112 6

50

27 9

106 0

3 8

2.8

29 5

24.9

93.6

40

18 3

87 0

3 8

2 8

25 2

21.5

76 6

35

14 9

70 0

3 8

2 8

13 3

11.3

38 3

20

8 0

35 0

3 8

2.8

FLA — Full Load Amps

FU — Dual Element Fuse or Circuit Breaker having high inrush

capability (max allowable amps)

ICF — Max Instantaneous Current Flow during start-up is the sum

of compressor LRA plus the FLA of all other motors in

the unit.

IFM

LRA

OFM

WSA

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Outdoor (Condenser) Fan Motor

Wire Sizing Amps per NEC equals 1.25 x FLA of the largest

motor plus the sum of all other motors in the unit.