50df, Electrical protection devices – Carrier MODU-PAC 50DF User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

50DF

As space temperature approaches the heating tempera

ture set point, heating stages cycle off.

During heating, economizer is limited to the minimum

position to provide minimum outdoor air for ventilation

requirements.

Operating

sequence

with

economizer

and

energy

management

Option/Accessory

(Using

electronic

thermostat or transmitter)

Clock in remote control box switches controls to DAY

(OCCUPIED) mode. Indoor air fan runs continually while

in DAY (OCCUPIED) mode.

If return air temperature is below the adjustable setting of

the morning warm-up thermostat, economizer remains

closed.

When return air temperature goes above the setting of

morning warm-up thermostat, economizer goes to adjust

able minimum position.

When thermostat calls for cooling and outdoor air

enthalpy is below setting of enthalpy controller, economizer

modulates open. (If outdoor air enthalpy is above enthalpy

set point, economizer remains at minimum position.) The

economizer acts as first stage of cooling, providing “free

cooling” with outside air. If outside air alone cannot satisfy

cooling requirements of conditioned space, economizer

cooling is integrated with mechanical cooling.

Compressor(s), working simultaneously with econo

mizer, will be staged on to meet cooling load.

As conditioned space temperature approaches the

thermostat’s cooling set point, stages cycle off, last stage

first. After all stages of mechanical cooling are off, econo

mizer modulates to minimum position.

During cooling cycle, a discharge air sensor senses dis

charge air temperature. If discharge air temperature drops

below 62 F, economizer starts to modulate toward minimum

position. At 50 F, economizer wil be at minimum position.

At end of the DAY (OCCUPIED) mode on the clock, unit

controls enter NIGHT (UNOCCUPIED) mode. Econo

mizer closes. Indoor air fan runs only on a call for heating

or cooling. The temperature controls go into a HEATING

SETBACK, COOLING SETUP or COOLING SHUT

DOWN mode.

The HEATING SETBACK is field selectable at the unit

for 5, 8, 12 or 15 F below set point on the room thermostat.

The COOLING SETUP is field selectable at unit for 5,8,

or 12 F above the set point on the room thermostat.

During the UNOCCUPIED mode, unit continues to use

economizer cooling first and then integrates economizer

cooling

with

mechanical

cooling

to

meet

cooling

requirements.

A 5-hour manual bypass timer is located in the remote

control box to provide for times when air conditioning is

needed during normally unoccupied hours.

Two-speed indoor fan option

The 2-speed indoor fan staging sequence is based upon

room demand. As the conditioned space requires cooling,

this cooling demand is transmitted from the room thermo

stat to the logic panel. Up to 4 stages of cooling can be

sequenced on to meet the demand from the conditioned

space.

As shown in the 2-speed indoor fan staging tables, the

high fan speed is used only if and when needed.

When outdoor air enthalpy permits economizer opera

tion, the indoor fan runs at high speed only when necessary

to take maximum advantage of oufside air to provide cool

ing. Low speed is used when modulating economizer can

handle the cooling load.

When outdoor air enthalpy does not permit economizer

operation, the economizer dampers remain at minimum

position and the indoor fan motor runs at high speed only

when cooling is at its highest demand.

During HEATING mode, the fans operate at low speed

for ventilation only, and at high speed at all times during

active heating.

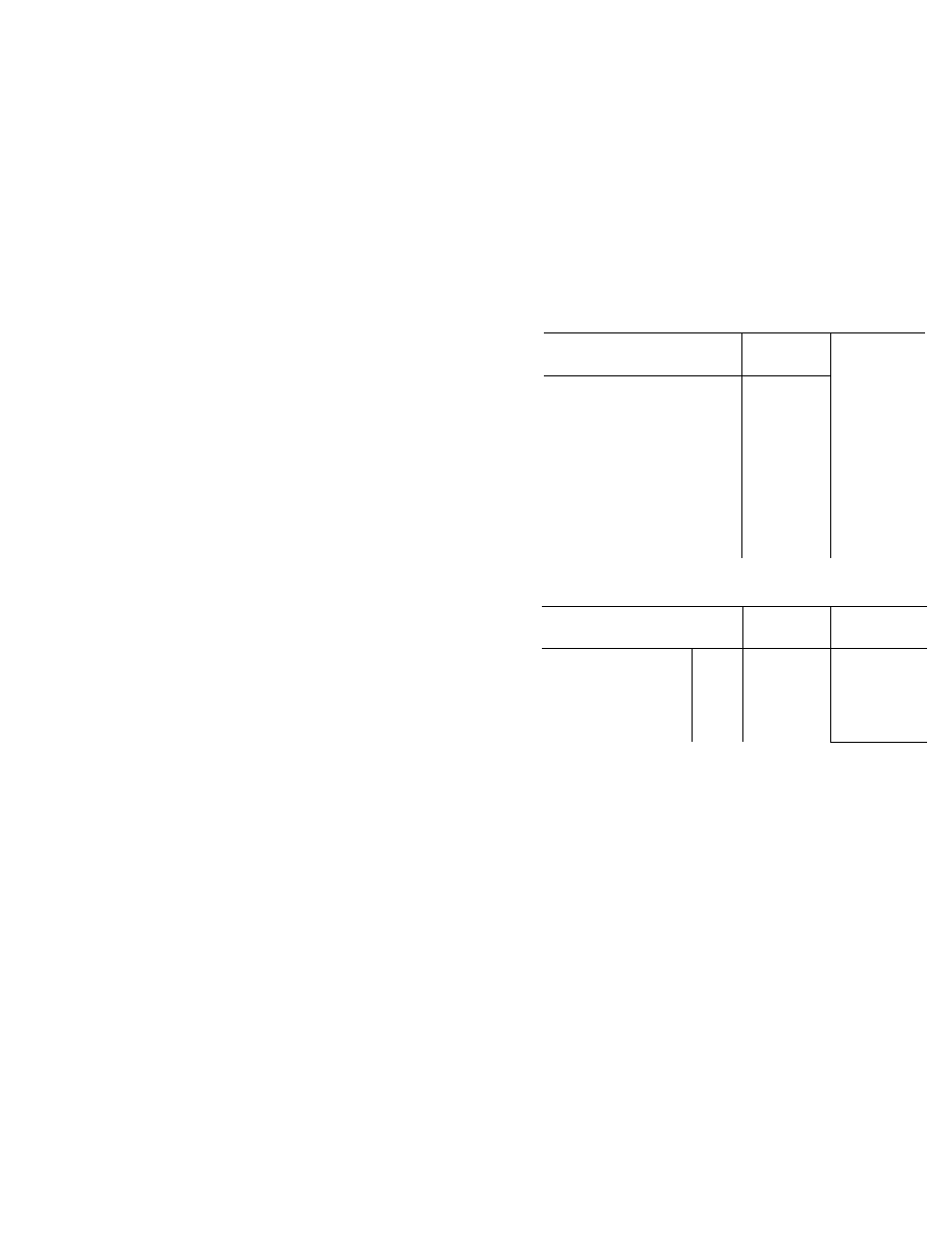

TWO-SPEED INDOOR AIR FAN STAGING

ECONOMIZER COOLING (Enthalpy Permitting)

.................................................................r

OPERATING

i

CONDITION i

FAN

SPEED

ECONOMIZER

DAMPER

POSITION

COMPRESSOR

OPERATtON

No Call for Cooling {

(Vent Air)

I

Low

Min

Position

Off

Step 1 1

(Call for Minimum Cooling) !

Low

Modulating

Between

Min and Full

Open

Off

Step 2

1

(Economizer Cooling) *

High

Full Open

Off

Step 3 1

(Integrated |

Econ /Mech Cooling) |

High

Full Open

Compr 1

Step 4

(Integrated |

Econ /Mech Cooling) |

High

Full Open

Compr and 2

MECHANICAL COOLING

(Enthalpy Not Permitting Economizer Cooling)

OPERATING

i

FAN

CONDITtON j SPEED

ECONOMIZER

DAMPER

POSnrtON

COMPRESSOR

OPERATiON

No Cali for Cooling

(Ventilation Air)

Step 1

Step 2

Step 3

Step 4

Low

Low

Low

Low

High“

Min Position

Min F*osition

Min Position

Min Position

Min Position

Off

'ofl

Compr 1

Compr 1 and 2

Compr 1 and 2

Electrical protection devices

Compressor circuit breakers, calibrated for specific

applications, are current sensitive and temperature com

pensated to shut off compressor if current draw is excessive.

Must be manually reset.

Inherent compressor thermal protection with auto

matic reset de-energizes control circuit if extreme motor

temperature should occur due to excessive suction gas

temperature or motor overloading.

Low-pressure switch automatically shuts off compressor

if refrigerant pressure drops below setting for loss-of-charge

protection.

Fusible plugs, located in refrigerant system, protect

against excessive pressures or temperatures in case of fire

or other abnormal high-temperature condition.

Inherent outdoor fan motor protection with auto

matic reset — Power circuit opens if motor temper^ure

becomes excessive.

Indoor fan motor circuit breakers — These manually

reset circuit breakers protect against fan motor overload.

Limit switches, heat limiters and overcurrent circuit

breakers provide thermal and overcurrent protection for

electric resistance heaters.

17