2 measurement in pipelines, Measurement in pipelines -8 – YSI IQ SensorNet ViSolid Sensor 700 IQ User Manual

Page 20

3 - 8

ba76040e04

05/2014

Commissioning

ViSolid

®

700 IQ (SW)

3.4.2

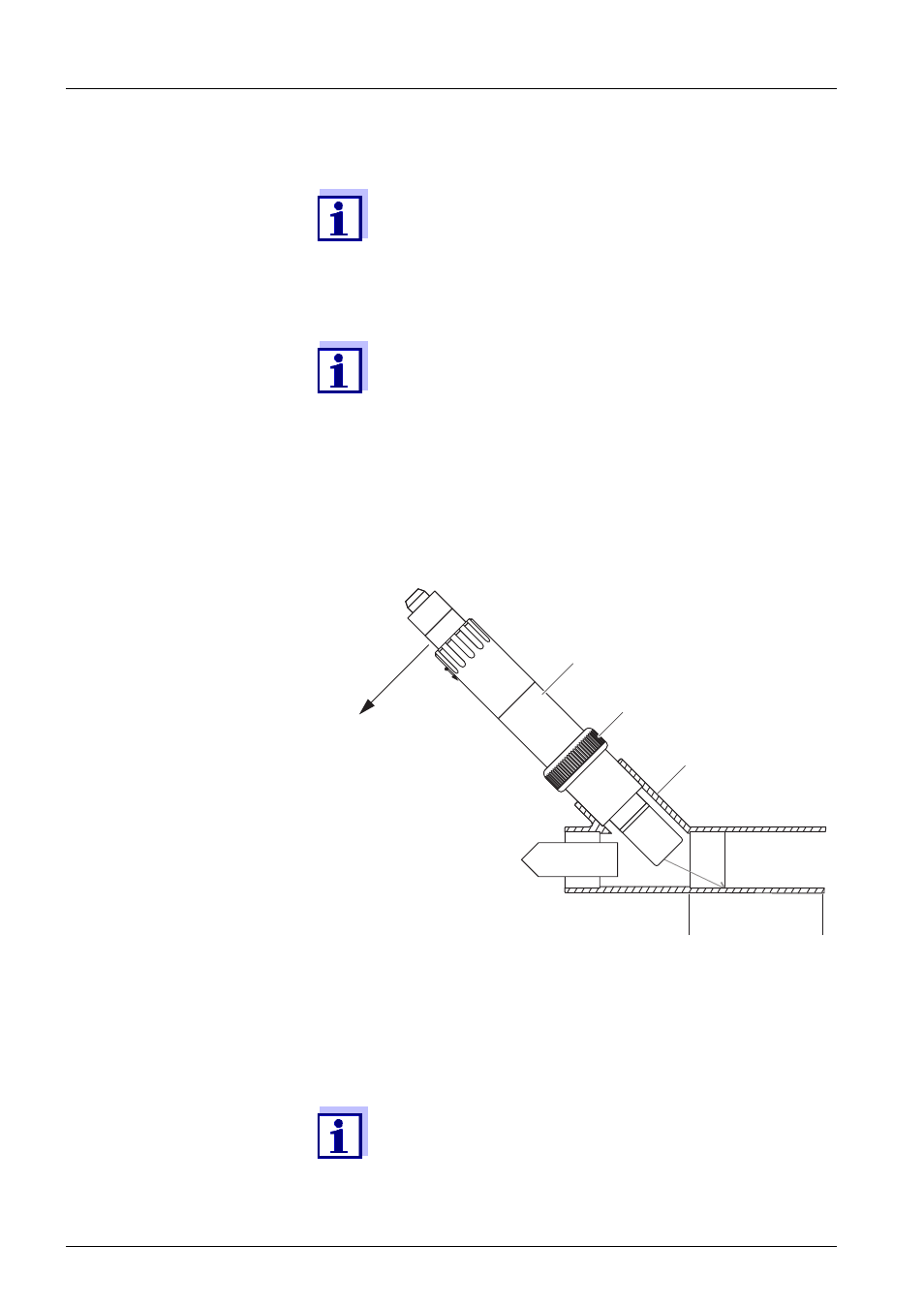

Measurement in pipelines

If deposits occur on the pipe walls, the calibration should be repeated

at regular intervals.

Example:

45 ° pipe installation

The pipe should be straight for a length of approx. 25 cm beyond the

installation location. Angled or tapered pipes can cause interference

effects in the case of low levels of total suspended solids.

Fig. 3-5

Total suspended solids sensor in the pipe with EBST 700-DU/N flow-thru

adapter

Fig. 3-5 shows the installation of the EBST 700-DU/N flow-thru adapter

for installation in a pipeline (DN 50). The infrared beam points in the

opposite direction to the direction of flow. The marking on the sensor

points towards the pipeline (see Fig. 3-5).

If there is a low level of total suspended solids (< 2000 mg/

l SiO2 or < 1000 mg/l TSS), the effects of the measurement

environment can simulate a higher content of total sus-

pended solids. The effect of the measurement environment

can be reduced by ensuring the optimum conditions (see

section 3.3.2).

If an optimum installation is not possible due to the struc-

tural conditions at the measuring location (e.g. in narrow

pipelines), the effects of the measurement environment

can be compensated by user calibration (see section

4.2.4).

For exceptions to the direction of flow, see section

3.3.3 F

ADA-DF 9

EBST 700-DU/N

ca. 25 cm

straight pipe

Marking aid

in this direction

Swivel nut

Infrared beam

Direction

of flow