Viconics VZ7656E Installation Guide User Manual

Page 21

21 | VZ7656E1000W Installation Guide

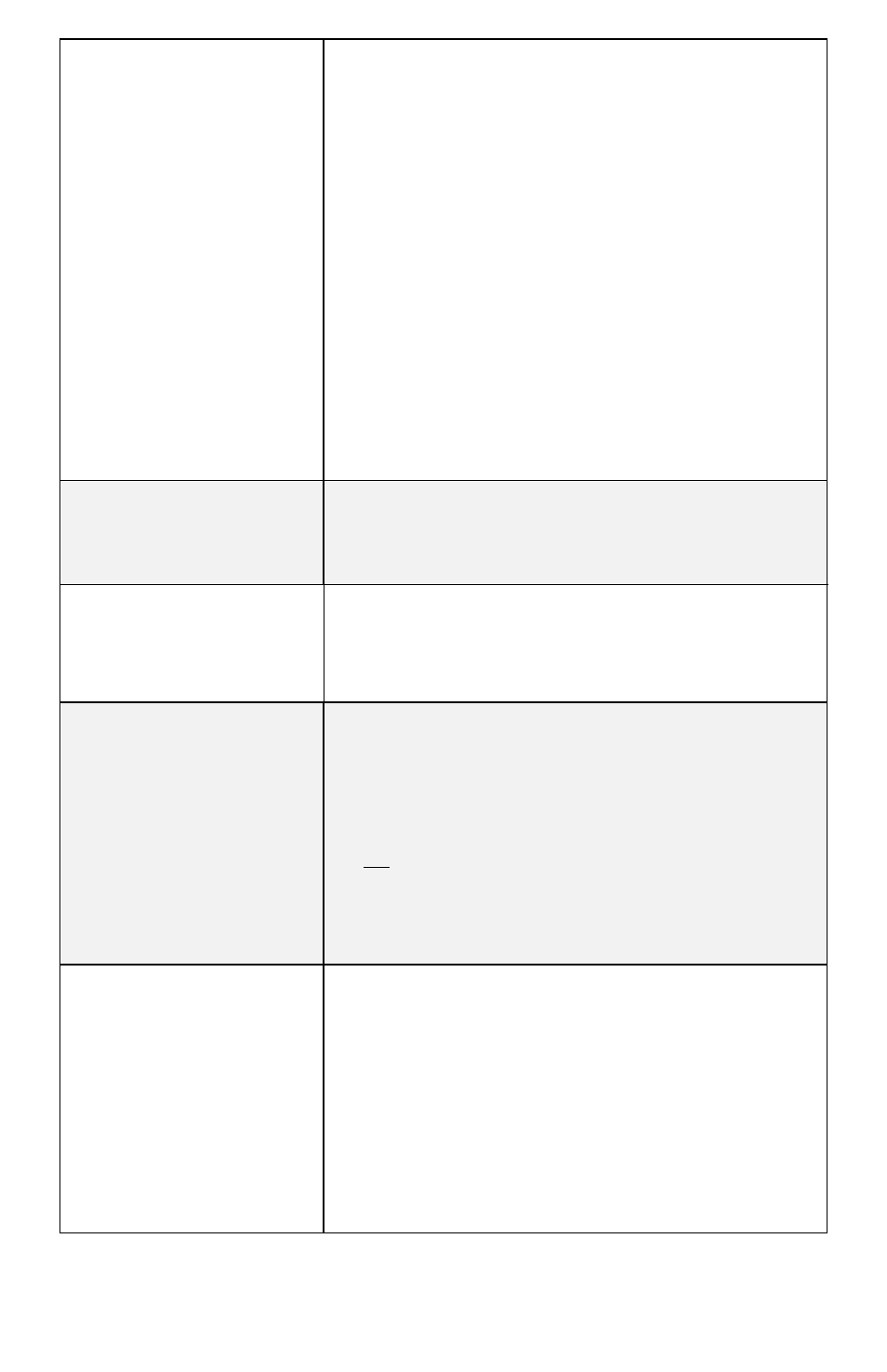

CntrlTyp

Sets how the Zones attached

to the RTU controller vote to

determine the actual system

mode of operation.

(Heat or Cool)

Default Value:

1 = AV_H3

This parameter will select the type of operation required

for the RTU based on the size of the system. Please refer

to the Viconics Zoning System Guide for recommended

settings.

Only the Zones that actually have values above 0% in

their (PIHT Wei & PICL Wei) configuration parameters

will be able to vote on the RTU operational mode

calculation.

0 =Highest: The highest PI Heating or PI Cooling

demand from the selected voting zones will dictate

heating or cooling operation of the RTU controller.

1 = AV_H3: The average of the 3 highest PI Heating or PI

Cooling demands from the selected voting zones will

dictate heating or cooling operation of the RTU controller.

2 = AV_H5: The average of the 5 highest PI Heating or

PI Cooling demands from the selected voting zones will

dictate heating or cooling operation of the RTU controller.

Dis HL

Discharge air temperature

high limit

Default: 120°F

Discharge air high temperature value at which the heating

stages will be locked out.

70°F to 150°F (21°C to 65°C)

(increments: 0.5° or 5°)

Dis LL

Discharge air temperature low

limit

Default: 45°F

Discharge air low temperature value at which the cooling

stages will be locked out.

35 to 65°F (2.0°C to 19.0°C)

(increments: 0.5° or 5°)

Anticycl

Minimum On-Off operation

time for stages

Default value = 2 minutes.

Minimum On-Off operation time of cooling & heating

stages.

IMPORTANT, anti-short cycling can be set to 0 minutes

for equipment that possess their own anti cycling timer.

Do not use this value unless the equipment has the above

mentioned internal timer. Failure to follow this guideline

may lead to damaged equipment.

0, 1, 2, 3, 4 & 5 minutes.

Heat cph

Heating stages cycles per

hour

Default value = 4 C.P.H.

Will set the maximum number of heating stage cycles per

hour under normal control operation. It represents the

maximum number of cycles that the equipment will be

turned on and off in the span of an hour.

Note that a higher C.P.H will represent a higher accuracy

of control at the expense of wearing down mechanical

components faster

.

3, 4, 5, 6,7 & 8 C.P.H.