VACUUBRAND BVC professional G User Manual

Page 57

+

If the old diaphragm is difficult to separate

from the diaphragm support disc, immerse

assembly in naphtha or petroleum ether. Do

not inhale vapors!

+

Check for washers between the diaphragm

support disc and the connecting rod. Make

sure that the original number is reassembled.

➨

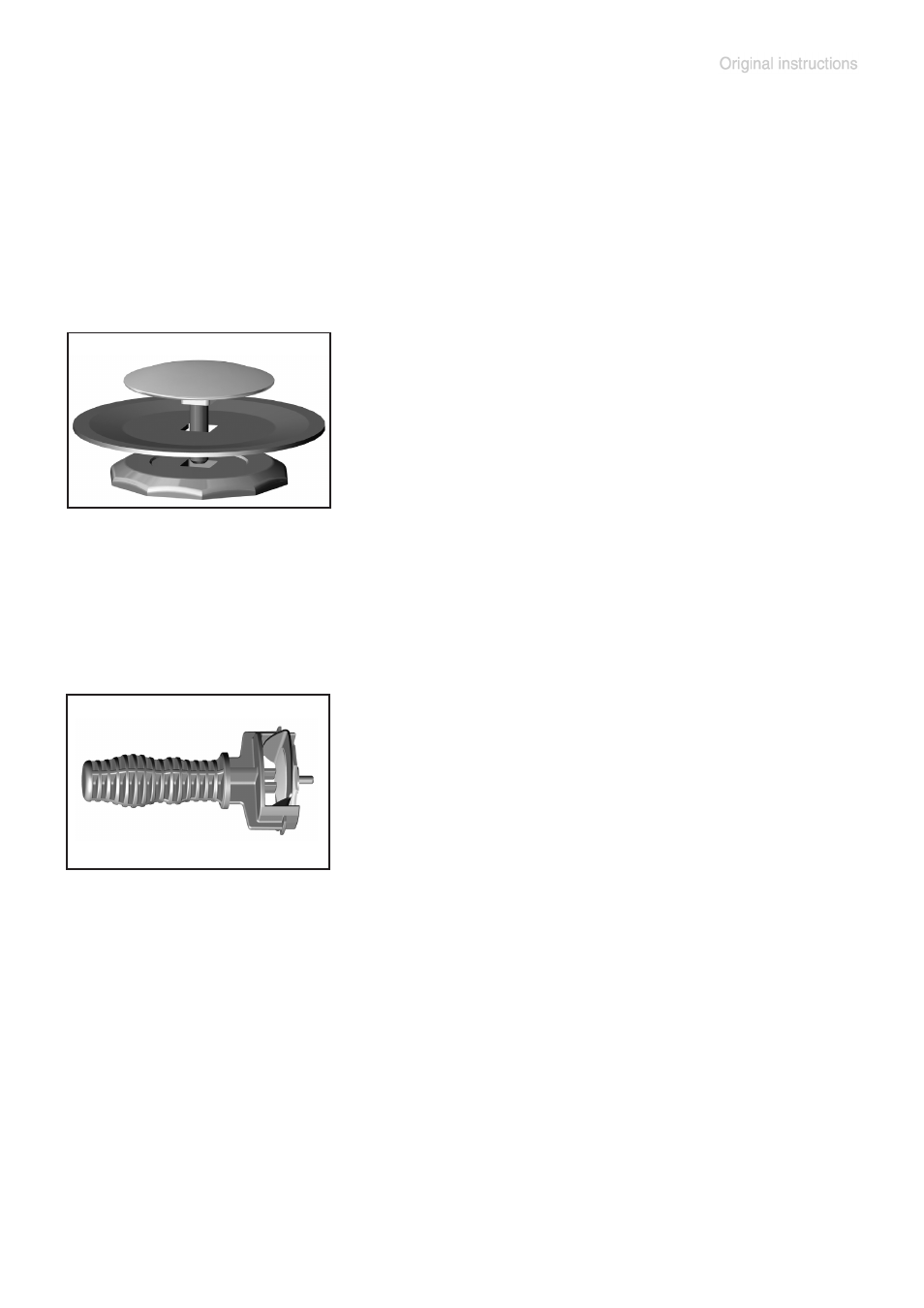

Position new diaphragm between diaphragm

clamping disc with square head screw and

diaphragm support disc.

+

Note: Position diaphragm with pale side

towards diaphragm clamping disc (facing

pump chamber).

+

Make sure that the square head screw of the

diaphragm clamping disc is correctly seated

in the guide hole of the diaphragm support

disc.

➨

Lift the diaphragm at the side. Place the di-

aphragm carefully together with diaphragm

clamping disc and diaphragm support disc in

the diaphragm key.

+

Avoid damage of the diaphragm: Do not ex-

cessively bend or crease the diaphragm.

➨

Assemble the original number of washers

between diaphragm support disc and con-

necting rod.

+

Too few washers: The pump will not attain

vacuum specification. Too many washers:

Diaphragm clamping disc will hit head cover,

causing noisy operation and possibly caus-

ing the pump to seize up.